Focus on Vehicle Performance and Comfort

The Automotive Shock Absorbers for Commercial Vehicle Market is witnessing a heightened focus on vehicle performance and passenger comfort. As competition intensifies among commercial vehicle manufacturers, there is a growing emphasis on delivering superior driving experiences. Shock absorbers are integral to achieving this goal, as they directly influence ride quality and handling. Market data suggests that vehicles equipped with advanced shock absorber systems tend to have higher customer satisfaction ratings. Consequently, manufacturers are increasingly prioritizing the development of innovative shock absorber solutions to meet the evolving expectations of consumers in the Automotive Shock Absorbers for Commercial Vehicle Market.

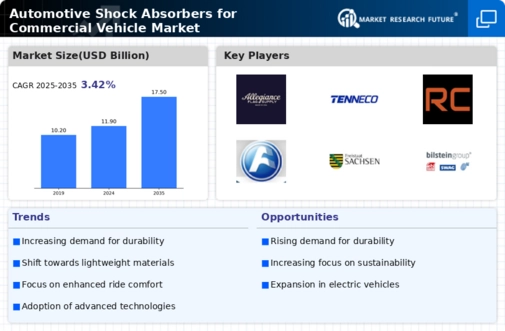

Increasing Demand for Commercial Vehicles

The Automotive Shock Absorbers for Commercial Vehicle Market is experiencing a notable surge in demand for commercial vehicles. This trend is largely driven by the expansion of e-commerce and logistics sectors, which require efficient transportation solutions. According to recent data, the commercial vehicle segment is projected to grow at a compound annual growth rate of approximately 4.5% over the next few years. This growth necessitates enhanced vehicle performance, where shock absorbers play a crucial role in ensuring stability and comfort. As commercial fleets expand, the need for reliable shock absorbers becomes paramount, indicating a robust market opportunity for manufacturers in the Automotive Shock Absorbers for Commercial Vehicle Market.

Sustainability and Eco-Friendly Solutions

Sustainability is becoming a pivotal driver in the Automotive Shock Absorbers for Commercial Vehicle Market. As environmental concerns rise, manufacturers are exploring eco-friendly materials and production processes for shock absorbers. The shift towards sustainable practices not only aligns with regulatory pressures but also caters to the growing consumer demand for environmentally responsible products. Companies that successfully integrate sustainability into their shock absorber designs may enhance their market position. This trend indicates a potential shift in the Automotive Shock Absorbers for Commercial Vehicle Market, where eco-conscious innovations could lead to new opportunities and competitive advantages.

Regulatory Compliance and Safety Standards

The Automotive Shock Absorbers for Commercial Vehicle Market is significantly influenced by stringent regulatory compliance and safety standards. Governments worldwide are implementing regulations aimed at improving vehicle safety and performance, which directly impacts the demand for high-quality shock absorbers. For instance, regulations concerning load capacity and vehicle stability require manufacturers to innovate and enhance their products. This compliance not only ensures safety but also promotes the adoption of advanced shock absorber technologies. As a result, companies that prioritize adherence to these regulations are likely to gain a competitive edge in the Automotive Shock Absorbers for Commercial Vehicle Market.

Technological Innovations in Shock Absorbers

Technological advancements are reshaping the Automotive Shock Absorbers for Commercial Vehicle Market. Innovations such as electronically controlled shock absorbers and adaptive damping systems are gaining traction, offering improved ride quality and handling. These technologies allow for real-time adjustments based on road conditions, enhancing vehicle performance. The integration of smart technologies is expected to drive market growth, as fleet operators seek to optimize their vehicles for efficiency and comfort. As the industry evolves, manufacturers that invest in research and development of cutting-edge shock absorber technologies will likely capture a larger share of the Automotive Shock Absorbers for Commercial Vehicle Market.