Expansion of Industrial Applications

The Automatic Tube Cleaning System Market is witnessing an expansion in industrial applications across various sectors. Industries such as HVAC, marine, and pharmaceuticals are increasingly recognizing the benefits of automatic tube cleaning systems. These systems are essential for maintaining the efficiency of heat exchangers and cooling systems, which are critical in these sectors. The growing awareness of the importance of equipment maintenance and the potential cost savings associated with automatic cleaning solutions are driving this trend. As more industries adopt these systems, the market is expected to expand, with a projected increase in demand for customized solutions tailored to specific industrial needs.

Regulatory Compliance and Safety Standards

The Automatic Tube Cleaning System Market is significantly influenced by stringent regulatory compliance and safety standards. Industries are increasingly required to adhere to environmental regulations that mandate the reduction of emissions and waste. Automatic tube cleaning systems help companies meet these regulations by ensuring that equipment operates at optimal efficiency, thereby minimizing the risk of leaks and emissions. Furthermore, the implementation of these systems enhances workplace safety by reducing the need for manual cleaning, which can expose workers to hazardous conditions. As regulations become more stringent, the demand for automatic tube cleaning systems is likely to rise, as companies seek to avoid penalties and maintain compliance.

Rising Energy Costs and Resource Management

The Automatic Tube Cleaning System Market is also driven by the rising energy costs and the need for effective resource management. As energy prices continue to fluctuate, industries are compelled to seek solutions that enhance energy efficiency. Automatic tube cleaning systems play a crucial role in maintaining the efficiency of heat exchangers, which are vital for energy transfer in various applications. By ensuring that these systems operate without fouling, companies can significantly reduce energy consumption and operational costs. The market is expected to witness a notable increase in adoption as organizations prioritize energy conservation and sustainable practices, aligning with the global push towards greener technologies.

Technological Innovations and Smart Systems

The Automatic Tube Cleaning System Market is benefiting from rapid technological innovations and the integration of smart systems. Advancements in sensor technology, IoT, and automation are transforming traditional cleaning methods into more sophisticated solutions. These innovations allow for real-time monitoring and predictive maintenance, which can further enhance the efficiency of tube cleaning operations. As industries increasingly adopt smart technologies, the demand for automatic tube cleaning systems is likely to grow. The ability to collect and analyze data on system performance not only improves operational efficiency but also aids in decision-making processes, making these systems an attractive investment for many organizations.

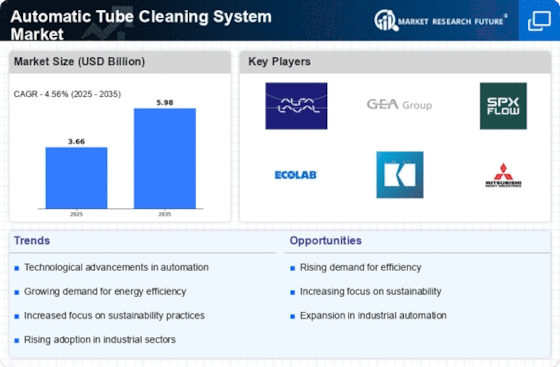

Increased Efficiency in Industrial Processes

The Automatic Tube Cleaning System Market is experiencing a surge in demand due to the increasing need for efficiency in industrial processes. Industries such as power generation, petrochemicals, and food processing are adopting these systems to minimize downtime and enhance operational efficiency. By automating the cleaning of heat exchangers and other tubular equipment, companies can reduce maintenance costs and improve energy efficiency. Reports indicate that the market for automatic tube cleaning systems is projected to grow at a compound annual growth rate of approximately 6% over the next five years. This growth is driven by the need for continuous operation and the reduction of manual labor, which aligns with the broader trend of automation in various sectors.