Rising Demand for Automation

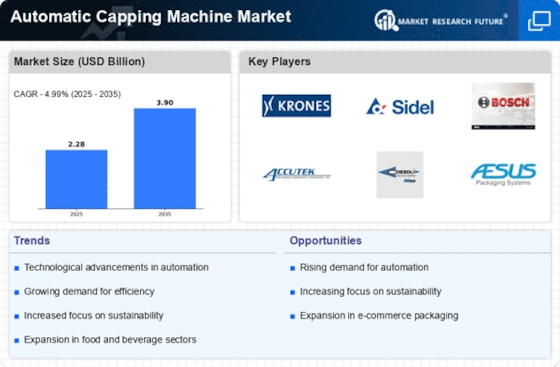

The Automatic Capping Machine Market is experiencing a notable surge in demand for automation across various sectors. Industries such as food and beverage, pharmaceuticals, and cosmetics are increasingly adopting automated solutions to enhance production efficiency. This shift is driven by the need to reduce labor costs and improve consistency in product quality. According to recent data, the automation market is projected to grow at a compound annual growth rate (CAGR) of approximately 10% over the next five years. As manufacturers seek to streamline operations, the integration of automatic capping machines becomes essential, thereby propelling the market forward.

Expansion of Packaging Industry

The Automatic Capping Machine Market is closely linked to the expansion of the packaging sector. With the increasing production of packaged goods, there is a heightened need for efficient capping solutions. The packaging industry is projected to grow significantly, driven by consumer preferences for convenience and safety. This growth is likely to create new opportunities for automatic capping machine manufacturers, as companies seek to enhance their packaging processes. The demand for innovative capping solutions that cater to diverse packaging formats is expected to rise, thereby contributing to the overall growth of the automatic capping machine market.

Increased Focus on Quality Control

Quality control remains a pivotal concern within the Automatic Capping Machine Market. As consumer expectations rise, manufacturers are compelled to implement stringent quality assurance measures. Automatic capping machines play a crucial role in ensuring that products are sealed correctly, thereby preventing contamination and ensuring product integrity. The market for quality control solutions is expected to expand, with investments in advanced capping technologies that offer precision and reliability. This trend indicates a growing recognition of the importance of quality in maintaining brand reputation and customer satisfaction, further driving the demand for automatic capping machines.

Technological Innovations in Machinery

Technological innovations are reshaping the Automatic Capping Machine Market. Advancements in machine design, such as the integration of smart technologies and IoT capabilities, are enhancing the functionality and efficiency of capping machines. These innovations allow for real-time monitoring and data collection, enabling manufacturers to optimize their production processes. The introduction of user-friendly interfaces and automated adjustments further streamlines operations. As technology continues to evolve, the market is likely to witness an influx of sophisticated capping solutions that meet the demands of modern manufacturing environments.

Regulatory Compliance and Safety Standards

Regulatory compliance is a critical driver within the Automatic Capping Machine Market. As industries face increasing scrutiny regarding safety and quality standards, the demand for capping machines that adhere to these regulations is on the rise. Manufacturers are investing in equipment that not only meets but exceeds safety requirements, ensuring that products are sealed securely and safely. This trend is particularly evident in sectors such as pharmaceuticals and food and beverage, where compliance with stringent regulations is paramount. The focus on safety and compliance is expected to bolster the market for automatic capping machines, as companies prioritize risk management and consumer safety.