Regulatory Compliance and Standards

Regulatory frameworks surrounding workplace safety and product integrity are becoming increasingly stringent, which positively impacts the Anti-Static Fibre Market. Industries such as electronics, pharmaceuticals, and aerospace are mandated to adhere to specific standards that require the use of anti-static materials. Compliance with these regulations not only ensures safety but also enhances product reliability. As companies strive to meet these standards, the demand for anti-static fibres is likely to increase. This trend indicates a growing awareness of the importance of static control in various sectors, thereby bolstering the market.

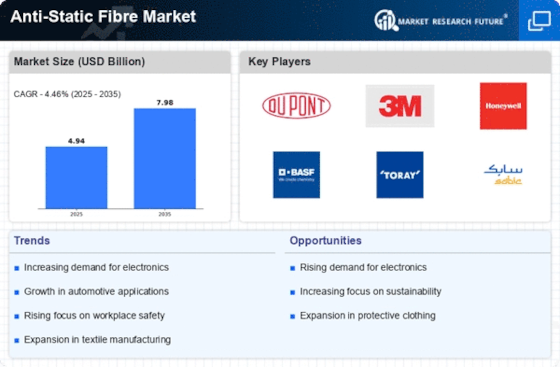

Innovations in Textile Manufacturing

Innovations in textile manufacturing processes are playing a crucial role in shaping the Anti-Static Fibre Market. Advances in technology have led to the development of new anti-static materials that are not only effective but also cost-efficient. These innovations enable manufacturers to produce high-quality anti-static fibres that meet the evolving needs of various industries. The textile industry is projected to grow at a rate of approximately 5% annually, which could further enhance the demand for advanced anti-static solutions. This trend indicates that the market is poised for growth as manufacturers seek to leverage new technologies to improve product offerings.

Expansion of E-Commerce and Logistics

The rise of e-commerce has led to a significant transformation in the logistics and packaging sectors, which in turn fuels the Anti-Static Fibre Market. With the increasing volume of electronic goods being shipped, the need for anti-static packaging solutions has surged. Anti-static fibres are essential in preventing electrostatic discharge during transportation, thereby protecting sensitive electronic components. The logistics sector is expected to grow at a rate of around 6% annually, indicating a robust market for anti-static solutions. This expansion highlights the critical role that anti-static fibres play in ensuring product integrity during transit.

Increasing Adoption in Automotive Industry

The Anti-Static Fibre Market is experiencing a notable increase in demand from the automotive sector. As vehicles become more technologically advanced, the need for materials that can mitigate static electricity is paramount. Anti-static fibres are utilized in various automotive applications, including interior fabrics and electronic components. The automotive industry is projected to grow at a compound annual growth rate of approximately 4.5% over the next few years, which could further drive the demand for anti-static fibres. This trend suggests that manufacturers are increasingly prioritizing safety and performance, thereby enhancing the overall market for anti-static fibres.

Rising Awareness of Static Electricity Hazards

There is a growing awareness regarding the hazards associated with static electricity, which is significantly influencing the Anti-Static Fibre Market. Industries that handle sensitive electronic components are increasingly recognizing the risks posed by static discharge, leading to a heightened demand for anti-static solutions. Educational initiatives and industry seminars are contributing to this awareness, prompting companies to invest in anti-static materials. This trend suggests that as more organizations understand the implications of static electricity, the market for anti-static fibres will likely expand, driven by a proactive approach to safety.