Technological Innovations

Technological advancements play a pivotal role in shaping the Amorphous Polyalphaolefin Market. Innovations in polymer chemistry and processing techniques have led to the development of high-performance materials with enhanced properties. For instance, the introduction of advanced catalysts has improved the efficiency of polymerization processes, resulting in better product quality and reduced production costs. The market is expected to grow as manufacturers leverage these technologies to create tailored solutions for various applications, including adhesives, coatings, and sealants. The increasing integration of automation and digitalization in manufacturing processes further streamlines operations, potentially increasing output and reducing waste. This technological evolution is likely to attract new players and investments, fostering a competitive landscape.

Growing Consumer Awareness

Consumer awareness regarding product quality and performance is increasingly influencing the Amorphous Polyalphaolefin Market. As end-users become more informed about the benefits of high-performance materials, demand for amorphous polyalphaolefins is expected to rise. This awareness is particularly pronounced in sectors such as packaging and consumer goods, where product integrity and safety are paramount. Manufacturers are responding by emphasizing the superior properties of their products, such as enhanced durability and resistance to environmental factors. The market is likely to see a shift towards premium products as consumers prioritize quality over cost. This trend may encourage manufacturers to invest in marketing strategies that highlight the advantages of amorphous polyalphaolefins, thereby expanding their market presence.

Sustainability Initiatives

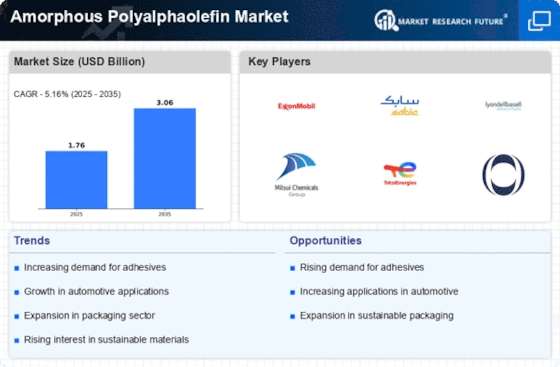

The Amorphous Polyalphaolefin Market is increasingly influenced by sustainability initiatives. As environmental concerns rise, manufacturers are compelled to adopt eco-friendly practices. This shift is evident in the growing demand for sustainable materials, which has led to innovations in production processes. Companies are exploring bio-based alternatives and recycling methods to reduce their carbon footprint. The market is projected to witness a compound annual growth rate (CAGR) of approximately 5% over the next few years, driven by these sustainability efforts. Furthermore, regulatory frameworks are becoming more stringent, pushing industries to comply with environmental standards. This trend not only enhances the market's appeal but also encourages investment in research and development for sustainable solutions.

Diverse Application Spectrum

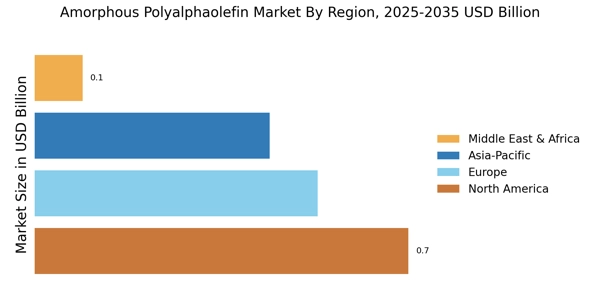

The Amorphous Polyalphaolefin Market benefits from a diverse application spectrum that spans multiple sectors. These materials are utilized in automotive, packaging, and construction industries, among others. The automotive sector, in particular, is witnessing a surge in demand for lightweight and durable materials, which enhances fuel efficiency and performance. In packaging, the need for flexible and high-performance materials is driving growth, as manufacturers seek to improve product shelf life and reduce waste. The market is projected to expand as new applications emerge, particularly in the realm of medical devices and consumer goods. This versatility not only broadens the market's reach but also encourages innovation, as companies strive to meet the evolving needs of various industries.

Rising Demand from Automotive Sector

The automotive sector is a significant driver for the Amorphous Polyalphaolefin Market, as manufacturers increasingly seek lightweight materials to enhance vehicle performance. The shift towards electric vehicles (EVs) further amplifies this demand, as EVs require advanced materials that contribute to energy efficiency. Amorphous polyalphaolefins are favored for their excellent thermal stability and low viscosity, making them ideal for applications such as adhesives and sealants in automotive assembly. The market is anticipated to grow as automotive manufacturers prioritize materials that improve fuel efficiency and reduce emissions. This trend is likely to foster collaborations between material suppliers and automotive companies, leading to innovative solutions that meet stringent regulatory requirements.