Growing Focus on Sustainable Practices

The Aerospace Insulation Coating Market is increasingly aligning with sustainability initiatives as manufacturers seek to minimize their environmental impact. The shift towards eco-friendly materials and processes is becoming a priority, driven by both regulatory pressures and consumer demand for greener solutions. Companies are exploring bio-based insulation coatings and recyclable materials to reduce waste and enhance sustainability. This trend is expected to foster innovation within the Aerospace Insulation Coating Market, as manufacturers strive to develop products that not only meet performance standards but also adhere to environmental guidelines. The integration of sustainable practices is likely to become a key differentiator in the competitive landscape.

Regulatory Compliance and Safety Standards

The Aerospace Insulation Coating Market is significantly influenced by stringent regulatory compliance and safety standards imposed by aviation authorities. These regulations necessitate the use of high-performance insulation coatings that can withstand extreme temperatures and environmental conditions. As safety remains a paramount concern in the aerospace sector, manufacturers are compelled to adopt advanced insulation solutions that meet or exceed these standards. The market is projected to grow as companies invest in research and development to create coatings that not only comply with regulations but also enhance the safety and reliability of aircraft. This focus on compliance is likely to drive innovation within the Aerospace Insulation Coating Market.

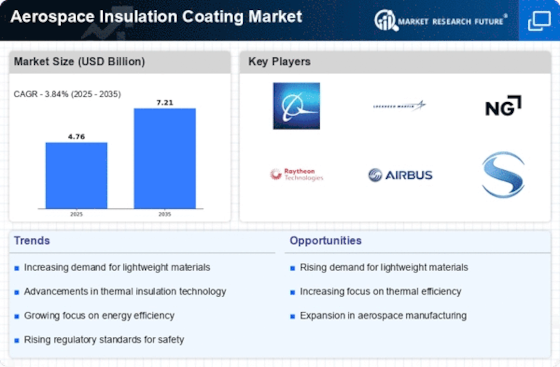

Increasing Demand for Lightweight Materials

The Aerospace Insulation Coating Market is experiencing a notable surge in demand for lightweight materials. This trend is primarily driven by the aerospace sector's ongoing efforts to enhance fuel efficiency and reduce emissions. Lightweight insulation coatings contribute significantly to weight reduction in aircraft, which is crucial for improving overall performance. According to recent data, the aerospace industry aims to achieve a 20% reduction in fuel consumption by 2030, which further propels the need for advanced insulation solutions. As manufacturers increasingly prioritize lightweight designs, the Aerospace Insulation Coating Market is poised for substantial growth, with innovations in materials and formulations playing a pivotal role in meeting these evolving requirements.

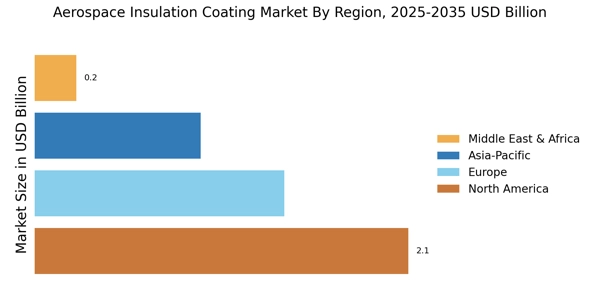

Expansion of Aerospace Manufacturing Capabilities

The Aerospace Insulation Coating Market is benefiting from the expansion of aerospace manufacturing capabilities across various regions. As new manufacturing facilities emerge and existing ones upgrade their technologies, the demand for high-quality insulation coatings is expected to rise. This expansion is driven by the increasing production rates of commercial and military aircraft, which necessitate advanced insulation solutions to ensure optimal performance. The market is projected to grow as manufacturers seek reliable and efficient insulation coatings that can withstand the rigors of aerospace applications. This trend indicates a robust future for the Aerospace Insulation Coating Market, as it adapts to the evolving needs of the aerospace sector.

Technological Innovations in Coating Applications

Technological advancements are reshaping the Aerospace Insulation Coating Market, with innovations in coating applications leading to enhanced performance and durability. The introduction of advanced application techniques, such as spray and dip coating, allows for more efficient and uniform coverage, which is essential for optimal insulation performance. Furthermore, the development of smart coatings that can monitor temperature and environmental conditions is gaining traction. These innovations not only improve the effectiveness of insulation coatings but also contribute to the overall longevity of aircraft components. As technology continues to evolve, the Aerospace Insulation Coating Market is likely to witness increased adoption of these cutting-edge solutions.