Rising Demand in Electronics

The Global Advanced Structural Ceramic Market Industry is benefiting from the increasing demand for advanced ceramics in the electronics sector. These materials are utilized in insulators, substrates, and other components due to their excellent electrical properties and thermal stability. As the electronics industry evolves, with trends such as miniaturization and the need for high-performance components, the demand for advanced ceramics is expected to rise. This growth is indicative of a broader trend towards integrating advanced materials in electronic applications, further solidifying the market's position in the global landscape.

Growing Demand in Aerospace Sector

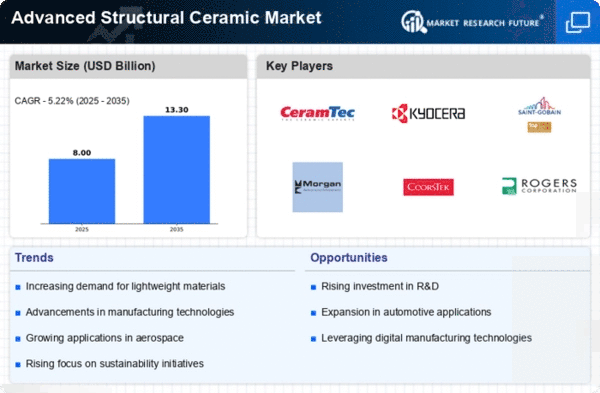

The Global Advanced Structural Ceramic Market Industry is witnessing a surge in demand from the aerospace sector, primarily due to the material's lightweight and high-temperature resistance properties. Advanced ceramics are increasingly utilized in turbine engines and structural components, enhancing fuel efficiency and performance. As the aerospace industry continues to expand, driven by rising air travel and the need for more efficient aircraft, the market for advanced ceramics is projected to grow significantly. This trend suggests that the market could reach approximately 7.6 USD Billion by 2024, reflecting the material's critical role in meeting the industry's stringent performance standards.

Increasing Applications in Defense

The Global Advanced Structural Ceramic Market Industry is experiencing heightened interest from the defense sector, where advanced ceramics are employed in armor systems, missile components, and other critical applications. These materials offer superior ballistic protection and thermal stability, which are essential for modern military operations. As nations invest in upgrading their defense capabilities, the demand for advanced ceramics is likely to increase. This trend is expected to contribute to the market's growth trajectory, potentially reaching 13.3 USD Billion by 2035, as defense budgets expand and the need for advanced materials becomes more pronounced.

Environmental Sustainability Initiatives

The Global Advanced Structural Ceramic Market Industry is increasingly influenced by environmental sustainability initiatives. Advanced ceramics are often favored for their durability and low environmental impact during production and use. As industries seek to reduce their carbon footprint and adhere to stricter environmental regulations, the demand for sustainable materials is likely to grow. This shift towards environmentally friendly solutions may drive the adoption of advanced ceramics across various sectors, contributing to the overall market growth and aligning with global sustainability goals.

Technological Advancements in Manufacturing

Technological innovations in the manufacturing processes of advanced ceramics are significantly influencing the Global Advanced Structural Ceramic Market Industry. Techniques such as additive manufacturing and advanced sintering methods are enhancing the production efficiency and scalability of these materials. These advancements not only reduce production costs but also improve the material properties, making them more attractive for various applications. As manufacturers adopt these technologies, the market is likely to witness a compound annual growth rate of 5.22% from 2025 to 2035, indicating a robust growth outlook driven by enhanced production capabilities.