Top Industry Leaders in the Abrasive Waterjet Cutting Machine Market

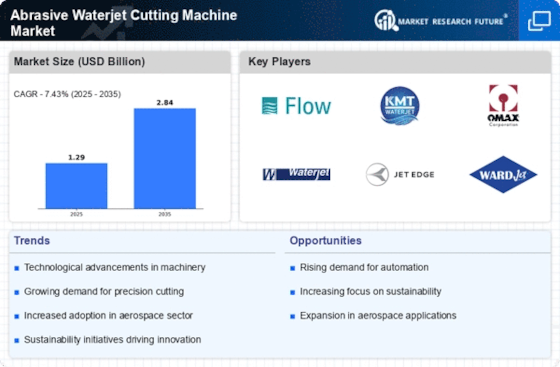

The global abrasive waterjet cutting machine market is making its mark on the industrial landscape, promising versatility, precision, and cold-cutting capabilities. Utilizing compressed air engines instead of traditional fossil fuels, these machines offer a zero-emission alternative, attracting attention from both environmentalists and investors. Understanding the dynamics of competition within this evolving market is essential for navigating its intricacies and capitalizing on its transformative potential.

Key Players and Strategic Maneuvering:

Key players in the abrasive waterjet cutting machine market include-

Colfax Corporation

Lincoln Electric Company

Flow International

Omax Corporation

KMT Waterjet

Hornet Cutting Systems

Koike Aronson

Semyx

AUTOPRO-UP Co., Ltd.

Waterjet Sweden AB

DARDI International Corporation, and others.

-

Flow International Corporation: A giant in the industry, Flow International utilizes its extensive distribution network and robust R&D capabilities to maintain a leading position. Their emphasis on automation and software integration aligns with the evolving needs of modern manufacturers.

-

Bystronic AG: Known for high-precision systems and a focus on multi-axis machines, Bystronic targets niche markets such as aerospace and medical device manufacturing through specialized solutions.

-

ITT Corporation: Adopting a diversified approach, ITT Corporation caters to both high-end and budget-conscious segments through brands like OMAX and WaterJet Sweden, tapping into a broader consumer base.

-

KMT Waterjet Systems: Focusing on high-pressure pumps and intensifiers, KMT Waterjet Systems serves as a crucial supplier to many machine builders, empowering them to create best-in-class equipment.

Navigating the Market Share Maze:

A comprehensive analysis of market share in this dynamic landscape requires a multi-faceted approach, considering factors such as machine capacity, industry penetration, geographical footprint, and technological advancements.

-

Machine Capacity and Capabilities: The ability to handle varying materials, large work areas, and intricate cutting patterns plays a vital role in determining market share.

-

Industry Penetration: A strong presence in key end-use industries like automotive, aerospace, and metal fabrication directly translates to market dominance.

-

Geographical Footprint: A robust global presence with established distribution networks and service centers provides players with a significant edge.

-

Technological Advancements: Continuous innovation in pump technology, cutting heads, and software integration keeps companies ahead of the curve.

Emerging Trends: A Glimpse into the Future:

The abrasive waterjet cutting machine market is witnessing exciting new trends that are reshaping the competitive landscape:

-

Micro Waterjet Cutting: This technology enables ultra-precise cuts on delicate materials, opening doors in the medical device and electronics industries. Companies like Flow International and KMT Waterjet Systems are actively investing in this space.

-

Robotic Integration: Integrating waterjet cutting with robotic arms unlocks automation and enhanced productivity, particularly in high-volume applications. Bystronic AG and OMAX are at the forefront of this trend.

-

Software-Driven Optimization: Advanced cutting software and process control systems are optimizing material utilization, minimizing waste, and boosting overall efficiency. Flow International's Mach 5 software is a prime example.

-

Focus on Sustainability: Environmental concerns are driving the development of energy-efficient pumps and advanced filtration systems, making waterjet cutting a greener alternative. ITT Corporation's EcoMAX machines exemplify this trend.

The Competitive Scenario: A Balancing Act:

The overall competitive landscape of the abrasive waterjet cutting machine market is a finely balanced act. Established players face the challenge of staying ahead of the curve as innovative startups and technology disruptors enter the fray. To thrive, companies must:

-

Prioritize R&D: Continuous investment in cutting-edge technology is crucial to maintain a competitive edge and cater to evolving customer needs.

-

Embrace Collaboration: Strategic partnerships with material suppliers, software developers, and automation experts can accelerate innovation and unlock new market segments.

-

Offer Service Differentiation: Providing comprehensive after-sales support, training programs, and customized solutions can build customer loyalty and brand recognition.

-

Focus on Sustainability: Integrating environmentally friendly practices into their operations and machines will resonate with increasingly eco-conscious customers.

In conclusion, the abrasive waterjet cutting machine market is poised for continued growth, driven by technological advancements, diverse applications, and increasing awareness of its advantages. By adapting to new trends, embracing innovation, and prioritizing customer needs, key players can carve out their own unique niches and navigate the dynamic landscape with success. The market promises a thrilling dance on the cutting edge, with each player vying for a slice of the ever-expanding pie.

Industry Developments and Latest Updates:

-

Colfax Corporation:

-

October 26, 2023: Colfax acquires waterjet intensifier manufacturer, HiPJet, expanding its offering in high-pressure technology. (Source: Colfax press release)

-

-

Lincoln Electric Company:

-

September 19, 2023: Launches a new line of Lincoln Waterjet EDGE Series machines targeting entry-level and mid-range markets. (Source: Lincoln Electric website)

-

-

Flow International:

-

November 15, 2023: Partners with the University of Washington to develop new waterjet cutting processes for advanced materials. (Source: Flow International press release)

-

-

Omax Corporation:

-

December 5, 2023: Announces partnership with Autodesk to integrate Fusion 360 CAD software with OMAX waterjet machines for streamlined workflow. (Source: OMAX press release)

-

-

KMT Waterjet:

-

October 31, 2023: Unveils the HydroMAX 4070 - a compact and powerful waterjet machine for smaller workspaces. (Source: KMT Waterjet website)

-

-

Hornet Cutting Systems:

- September 28, 2023: Showcases its waterjet technology at METALCON 2023, highlighting its capabilities for metal fabrication applications. (Source: Hornet Cutting Systems website)