Advancements in Material Science

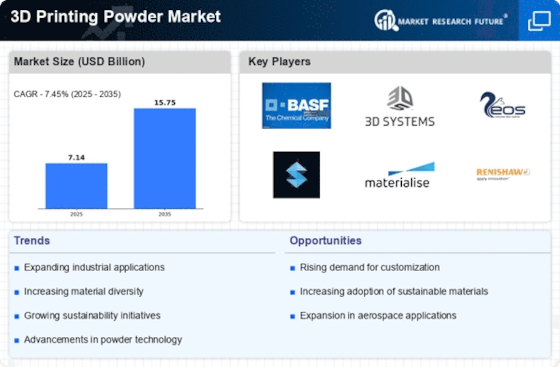

Innovations in material science are propelling the 3D Printing Powder Market forward. The development of new powder materials, such as high-performance polymers and metal alloys, expands the range of applications for 3D printing. For example, the introduction of composite powders that combine different materials can enhance mechanical properties and thermal resistance. This diversification allows industries to explore novel applications, from medical implants to complex aerospace components. The market for advanced materials is expected to grow significantly, with estimates suggesting a compound annual growth rate of over 20% in the coming years. Such advancements not only improve the quality of printed products but also broaden the scope of the 3D Printing Powder Market.

Increased Adoption in Healthcare

The healthcare sector is increasingly adopting 3D printing technologies, which significantly impacts the 3D Printing Powder Market. Customization of medical devices, prosthetics, and implants is becoming more prevalent, driven by the need for personalized solutions. The market for 3D printed medical devices is projected to reach USD 3 billion by 2025, reflecting a growing acceptance of these technologies. The ability to produce patient-specific solutions using biocompatible powders enhances treatment outcomes and patient satisfaction. As healthcare providers continue to explore the benefits of 3D printing, the demand for specialized powders is likely to rise, further stimulating the 3D Printing Powder Market.

Rising Demand for Lightweight Materials

The 3D Printing Powder Market experiences a notable surge in demand for lightweight materials, particularly in sectors such as aerospace and automotive. These industries increasingly prioritize materials that reduce weight while maintaining structural integrity. For instance, titanium and aluminum powders are gaining traction due to their favorable properties. The market for titanium powder alone is projected to reach approximately USD 1.5 billion by 2026, indicating a robust growth trajectory. This trend is driven by the need for fuel efficiency and performance enhancement, which lightweight materials can provide. As manufacturers seek to innovate and optimize their production processes, the 3D Printing Powder Market is likely to benefit from this growing emphasis on lightweight solutions.

Sustainability and Eco-Friendly Practices

Sustainability initiatives are increasingly influencing the 3D Printing Powder Market. Manufacturers are exploring eco-friendly materials and processes to reduce their environmental footprint. The use of recycled powders and biodegradable materials is gaining traction, aligning with global sustainability goals. For instance, the market for recycled metal powders is expected to grow as companies seek to minimize waste and promote circular economy practices. This shift not only addresses environmental concerns but also appeals to consumers who prioritize sustainable products. As the industry evolves, the integration of sustainable practices is likely to play a crucial role in shaping the future of the 3D Printing Powder Market.

Growing Investment in Research and Development

Investment in research and development is a critical driver for the 3D Printing Powder Market. Companies are allocating substantial resources to innovate and enhance their product offerings. This focus on R&D leads to the discovery of new materials and improved printing techniques, which can significantly impact production efficiency and product quality. For example, advancements in powder metallurgy are enabling the creation of finer powders that enhance the printing process. The global investment in additive manufacturing R&D is projected to exceed USD 1 billion by 2025, indicating a strong commitment to advancing the technology. Such investments are likely to yield breakthroughs that will further propel the 3D Printing Powder Market.