Rising Demand for Prototyping

The 3D Printing Plastics Market is experiencing a notable increase in demand for rapid prototyping across various sectors. Industries such as automotive, aerospace, and consumer goods are leveraging 3D printing technologies to create prototypes quickly and cost-effectively. This trend is driven by the need for faster product development cycles and the ability to test designs before mass production. According to recent data, the prototyping segment is projected to account for a significant share of the market, reflecting a shift towards more agile manufacturing processes. As companies seek to innovate and reduce time-to-market, the reliance on 3D printing for prototyping is likely to grow, further propelling the 3D Printing Plastics Market.

Increased Adoption in Healthcare

The healthcare sector is increasingly adopting 3D printing technologies, significantly impacting the 3D Printing Plastics Market. Applications such as custom implants, prosthetics, and surgical models are becoming more prevalent, driven by the need for personalized medical solutions. The ability to produce patient-specific devices using biocompatible plastics is revolutionizing treatment approaches. Market data indicates that the healthcare segment is expected to witness substantial growth, with investments in research and development aimed at enhancing the capabilities of 3D printing in medical applications. This trend not only improves patient outcomes but also highlights the versatility of 3D printing technologies, thereby expanding the scope of the 3D Printing Plastics Market.

Cost Efficiency and Material Savings

Cost efficiency is a critical driver for the 3D Printing Plastics Market, as businesses seek to optimize production costs. Traditional manufacturing methods often involve significant material waste and high labor costs. In contrast, 3D printing allows for additive manufacturing, which minimizes waste by using only the necessary amount of material. This efficiency translates into lower production costs and increased profitability for manufacturers. Recent studies suggest that companies utilizing 3D printing can reduce material costs by up to 30%, making it an attractive option for various industries. As organizations continue to prioritize cost-effective solutions, the demand for 3D printing technologies is likely to rise, further enhancing the 3D Printing Plastics Market.

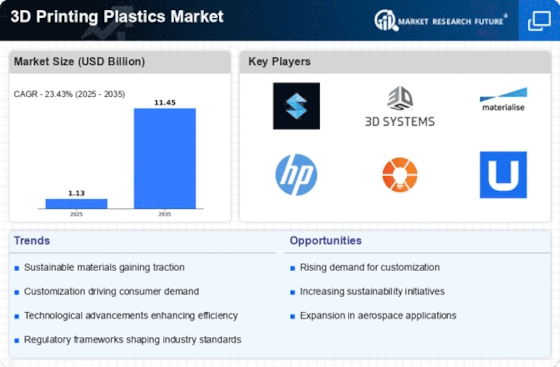

Growing Interest in Sustainable Materials

Sustainability is becoming a focal point in the 3D Printing Plastics Market, as consumers and businesses alike prioritize eco-friendly practices. The development of biodegradable and recyclable 3D printing materials is gaining traction, driven by increasing awareness of environmental issues. Companies are exploring sustainable alternatives to traditional plastics, which often contribute to pollution and waste. Market trends indicate a growing preference for materials that align with sustainability goals, prompting manufacturers to innovate and offer greener options. This shift not only addresses environmental concerns but also positions businesses favorably in a market that values corporate responsibility, thereby influencing the trajectory of the 3D Printing Plastics Market.

Expansion of Educational and Research Institutions

The expansion of educational and research institutions is significantly influencing the 3D Printing Plastics Market. As universities and research centers increasingly incorporate 3D printing technologies into their curricula and projects, the demand for 3D printing materials is expected to rise. These institutions are exploring innovative applications across disciplines, from engineering to art, fostering a culture of creativity and experimentation. Data suggests that educational institutions are investing heavily in 3D printing labs, which not only enhances learning experiences but also drives market growth. This trend indicates a burgeoning interest in 3D printing technologies among the next generation of professionals, potentially leading to increased adoption in various industries and further propelling the 3D Printing Plastics Market.