Growing Applications in Healthcare

The healthcare sector is increasingly recognizing the potential of the 3D Printing Ceramic Market, particularly in the production of biocompatible implants and prosthetics. Ceramics are favored for their compatibility with human tissue and their ability to be tailored for specific medical applications. Recent studies indicate that the use of 3D printed ceramics in healthcare could grow significantly, with projections suggesting a market expansion of over 20% in the coming years. This growth is indicative of the broader acceptance of 3D printing technologies in medical applications, which is likely to drive further investment and innovation within the 3D Printing Ceramic Market.

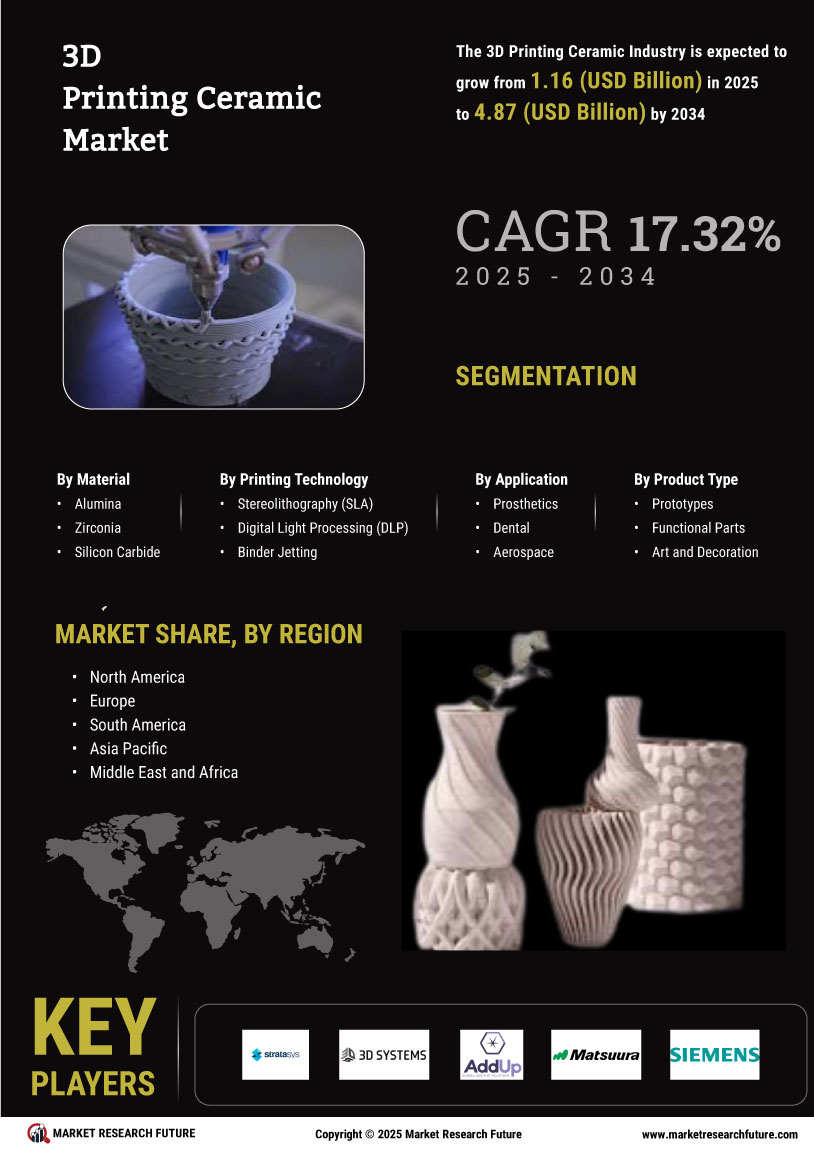

Rising Demand for Advanced Ceramics

The 3D Printing Ceramic Market is experiencing a notable increase in demand for advanced ceramics, driven by their superior properties such as high strength, thermal stability, and chemical resistance. Industries such as aerospace, automotive, and healthcare are increasingly adopting advanced ceramics for applications ranging from engine components to dental implants. According to recent data, the market for advanced ceramics is projected to grow at a compound annual growth rate of approximately 6.5% over the next five years. This trend indicates a robust potential for the 3D Printing Ceramic Market, as manufacturers seek innovative solutions to meet the evolving needs of these sectors.

Sustainability and Eco-Friendly Practices

Sustainability is becoming a central theme in the 3D Printing Ceramic Market, as manufacturers seek to adopt eco-friendly practices. The shift towards sustainable materials and processes is driven by increasing regulatory pressures and consumer demand for environmentally responsible products. Companies are exploring the use of recycled ceramics and bio-based materials in their 3D printing processes, which not only reduces waste but also lowers the carbon footprint associated with production. This trend is expected to enhance the market appeal of 3D printed ceramics, as sustainability becomes a key differentiator in the competitive landscape of the 3D Printing Ceramic Market.

Increased Investment in Research and Development

Investment in research and development within the 3D Printing Ceramic Market is on the rise, as companies strive to innovate and improve material properties. Enhanced research efforts are focused on developing new ceramic composites that exhibit better performance characteristics, such as increased durability and reduced weight. This trend is supported by funding from both private and public sectors, which is crucial for advancing technology in this field. As a result, the market is likely to witness the introduction of novel materials and applications, thereby expanding the scope of the 3D Printing Ceramic Market.

Integration of 3D Printing in Manufacturing Processes

The integration of 3D printing technologies into traditional manufacturing processes is transforming the 3D Printing Ceramic Market. This shift allows for more efficient production methods, reducing waste and lead times. As companies increasingly adopt additive manufacturing techniques, the demand for ceramic materials suitable for 3D printing is expected to rise. Recent estimates suggest that the additive manufacturing market, which includes ceramics, could reach a valuation of over 30 billion by 2026. This integration not only enhances production capabilities but also fosters innovation in product design, further propelling the growth of the 3D Printing Ceramic Market.