Growing Awareness and Acceptance

The 3D Printed Prosthetic Market is experiencing a surge in awareness and acceptance among healthcare professionals and patients alike. Educational initiatives and outreach programs are increasingly highlighting the benefits of 3D printed prosthetics, such as customization and rapid production. As more success stories emerge, showcasing the positive impact of these devices on users' lives, the stigma associated with prosthetics is gradually diminishing. Market Research Future indicates that approximately 60% of healthcare providers are now more inclined to recommend 3D printed options to their patients. This shift in perception is likely to foster greater trust in 3D printed solutions, encouraging more individuals to explore these alternatives. Consequently, the growing acceptance of 3D printed prosthetics is expected to significantly contribute to the expansion of the market, as it aligns with the evolving needs and preferences of users.

Supportive Regulatory Environment

The regulatory landscape surrounding the 3D Printed Prosthetic Market is becoming increasingly supportive, facilitating market growth. Regulatory bodies are recognizing the potential of 3D printing technology in healthcare and are working to establish guidelines that ensure safety and efficacy. This supportive environment encourages innovation and investment in the development of new prosthetic solutions. For instance, streamlined approval processes for 3D printed medical devices are being implemented, which can significantly reduce time-to-market for new products. As regulations evolve to accommodate the unique aspects of 3D printing, manufacturers are likely to feel more confident in pursuing new designs and technologies. This regulatory support may lead to a more dynamic and competitive market landscape, ultimately benefiting consumers by providing them with a wider array of high-quality prosthetic options.

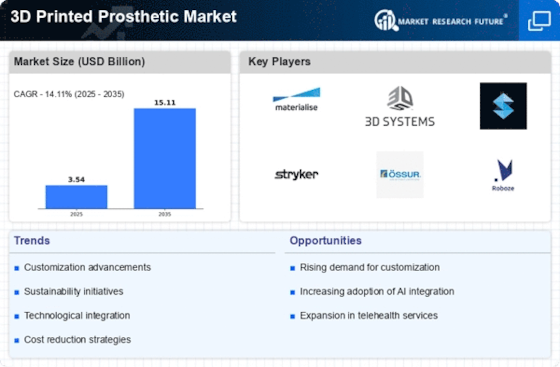

Advancements in 3D Printing Technology

Technological innovations are playing a pivotal role in shaping the 3D Printed Prosthetic Market. Recent advancements in materials and printing techniques have enhanced the quality and functionality of prosthetics. For instance, the introduction of biocompatible materials has improved the comfort and usability of 3D printed devices. Additionally, the integration of artificial intelligence and machine learning in design processes allows for more precise and tailored prosthetic solutions. As these technologies evolve, they are likely to lead to more efficient production methods, reducing lead times and costs. Market data indicates that the adoption of advanced 3D printing technologies could increase production efficiency by up to 50%. This continuous evolution in technology not only enhances product offerings but also attracts investment, further propelling the growth of the 3D Printed Prosthetic Market.

Rising Demand for Affordable Prosthetics

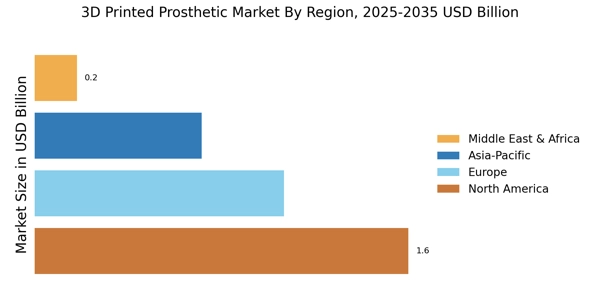

The 3D Printed Prosthetic Market is witnessing a notable increase in demand for affordable prosthetic solutions. Traditional prosthetics often come with high costs, making them inaccessible for many individuals. In contrast, 3D printing technology allows for the production of prosthetics at a fraction of the cost, potentially reducing expenses by up to 70%. This affordability is particularly crucial in regions with limited healthcare budgets, where the need for cost-effective solutions is paramount. As awareness of 3D printed options grows, more patients are likely to seek these alternatives, thereby driving market expansion. Furthermore, the ability to produce prosthetics on-demand can significantly reduce waiting times, enhancing patient satisfaction and encouraging adoption. This trend suggests that the 3D Printed Prosthetic Market may continue to thrive as it addresses the financial barriers associated with traditional prosthetic devices.

Increased Focus on Rehabilitation and Mobility

The 3D Printed Prosthetic Market is increasingly aligned with the broader focus on rehabilitation and mobility solutions. As healthcare systems prioritize patient-centered care, the demand for prosthetics that enhance mobility and support rehabilitation efforts is rising. 3D printed prosthetics can be designed to cater to specific activities, such as sports or daily tasks, thereby improving the quality of life for users. Market data suggests that the segment of active prosthetics is growing rapidly, with a projected increase of 25% in the next five years. This trend indicates a shift towards more functional and versatile prosthetic solutions, which are essential for individuals seeking to regain independence. The emphasis on mobility and rehabilitation is likely to drive innovation within the 3D Printed Prosthetic Market, as manufacturers strive to meet the evolving needs of users.