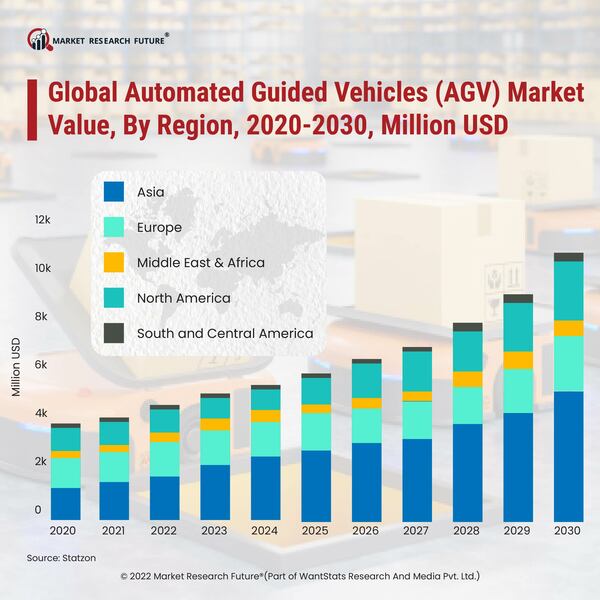

Innovations Promoting the Functionality of Automated Guided Vehicles

Automated Guided Vehicles (AGVs) are available in numerous forms and sizes in the market nowadays. They enable the transport of a wide range of objects, from lightweight pieces to extremely heavy weights such as a whole engine. Work-in-process mobility, production components delivery, pallet handling, finished product handling, and trailer loading are all areas where AGVs are increasingly being deployed. There are several benefits to automating industrial activities, including increased productivity, manufacturing flexibility, and production flow.

Automated guided vehicles have improved technologically, with various innovative vision, sensor, and movement technologies being brought to the market on a regular basis. Inuitive, a vision-on-chip processing firm, has made the most current advancement in sensor modules. On December 12, 2022, the company announced the release of two new sensor modules: the M4.5S and the M4.3WN. Both sensor modules are based on the NU4000 Vision-on-Chip (VoC) processor and merge depth sensing and image processing with AI and VSLAM capabilities to offer robotic devices with human-like visual awareness. They are designed to be readily integrated into robots and drone systems.

The M4.5S offers robots improved depth courtesy of stereo sensing, as well as AI-based obstacle detection and object identification. It has the industry's broadest field of vision at 88x58 degrees, the smallest minimum sensing range of 9 cm, and a wide dynamic working temperature range of up to 50 degrees Celsius. The M4.5S is a simple-to-use, extremely efficient platform. It is intended to serve as a self-contained depth sensor module, reducing time to market for commercial robotic systems with industrial design fixes and constraints. The M4.3WN has precise tracking and VSLAM navigation based on fisheye cameras, an IMU, depth sensing, and on-chip AI computation. This allows for free navigation, localization, path planning, and static and dynamic obstacle avoidance, all of which are major issues for AMR and AGV systems. According to the firm, the M4.3WN is precisely constructed in a metal casing to better serve in industrial environment settings. From logistics and aeronautical engineering to the medical business, AGVs have enormous inculcation potential, which is being pushed further by high-tech advancements in the industry.