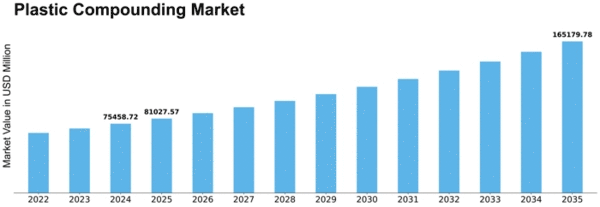

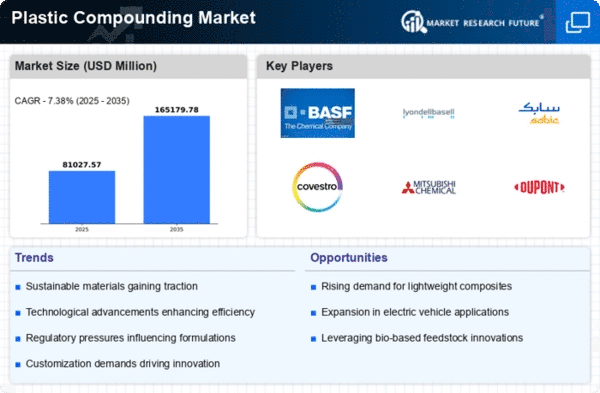

Plastic Compounding Size

Plastic Compounding Market Growth Projections and Opportunities

The United States has seen a significant growth in the polymeric plasticizers market that is indicative of the dynamic nature of plastics industry. They are useful for enhancing flexibility and durability as well as general performance of plastic materials. At present, however, there is an increase in demand for polymeric plasticizers driven by rising applications of flexible PVC (polyvinyl chloride) products in the construction, automotive and packaging sectors.

One reason why more polymeric plasticizers are needed in USA is because its construction sector is expanding. It finds extensive use in construction applications like floorings, cables and roofing membranes. Thus, it implies that they are key constituents which make them essential elements to all constructions since their elasticity and resilience need this requirement. Due to this fact, the residential as well as commercial building activities have increased requiring more consumption levels of these compounds.

Another major factor behind this rise in demand comes from the automobile sector. The flexible PVC is used on various parts inside autos such as interiors trims; wire and cable coatings; or gaskets. As such automobile manufacturers rely heavily on polymeric plasticizers for enabling car parts to remain flexible enough but still strong enough to meet stringent requirements set by the industry This means that Polymer Plasticizers are demanded more because vehicles continue to be invented every day.

Additionally, within America packaging represents a huge market segment with extensive use of polymeric plasticizer In order to realize sufficient levels of flexibility plus elasticity during fabrication of flexile packages like films and pouches; it depends if they contain large amounts or not . Modern customers have a preference for lightweight packages that can be carried around hence an increased demand over time for flexible packing material Thereby putting pressure upon producers across all sectors who aim at meeting modern package’s performance criteria so as to increase numbers .

Due to their mechanical enhancement properties on plastics materials besides chemical stability they also find application in other areas such as wire & cable insulation; medical devices; consumer goods etc. Thus polymeric plasticizers are being recognised as impenetrable additives across various sectors and industries.

The US market for polymeric plasticizers has seen increased R&D investments leading to innovative technologies that address environmental concerns (Sustainable Plasticizers). Hence, researchers now focus on developing eco-friendly plasticisers that will help eliminate their impact on the environment. At any rate this seems like a shift in the industry towards more sustainable alternatives.

Leave a Comment