The Rising Painting and Coating Sector: A Fueling Force for the Epoxy Resin Market

Versatility of Epoxy Resins to Add a Value to Their Use Across Different Industries

The versatile nature of epoxy resins helps them find applications in different end-user segments, driving the growth of the global epoxy resin market. The valuation of the realm of epoxy resins measured in 2023 and 2032 is USD 13.4 billion and USD 19.5 billion, respectively. The advancement of the sector is likely to occur at a CAGR of 3.2%.

Talking about the epoxy resin, this is one type of thermosetting polymer developed by copolymerization of an epoxide with some other compounds with two hydroxyl groups.

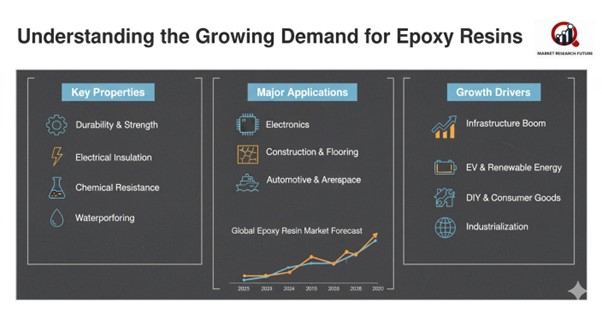

Epoxy resins are well-known for their enhanced and robust performance in different industrial applications. The reason behind this can be the fantastic properties that the material has.

For example, an excellent level of mechanical strength, high thermal stability, corrosion resistance, exceptional toughness, resistance to different chemicals and moisture, prolonged durability, and many more.

Epoxy resins are extensively found in applications across paints and coatings, electronic encapsulation, adhesives, and composites industries.

Advantages and Uses of Epoxy Resins

It can be said that epoxy resins are the best resins available in the industrial market. The supporting attributes of epoxy resins are resistance to thermal stress, degradation over time, and other excellent mechanical properties, which are recommended for most industrial environments.

If you want to make something corrosion-resistant, you can use epoxy resins. This covers a massive range of applications, and you can use this as an adhesive mass for walls, metal, plastic, carbon fiber, fiberglass, and more.

Besides, by combining different filler materials, such as porcelain and glass, you can make the resin more durable and attain more thermal and mechanical properties. This type of resin is utilized in reinforced plastic as a component of composite material. Besides, this can be adapted to match any substrates.

As they have a lower level of viscosity, epoxy resins effectively construct different reinforcing materials. Talking about one of the most advantageous properties of epoxy resins, the resin takes less time to shrink during the hardening process. Besides, while hardening, it creates a lower level of internal stress.

Some Advantages of Epoxy Resins

- It has a remarkable ability to adapt to different applications. Whether neutralization tanks, epoxy floor, corrosion protection, or separator vessels, epoxy resins offer increased resistance.

- Apart from this, epoxy resin can demonstrate high chemical stability. The material has excellent resistance to alkalis, salts, alkaline solvents, and acids that can be applied without issue in chemical processing areas.

- As the material is monolithic, this type of resin is also perfect for the food and beverage sector or the pharmaceutical industry.

- Experts recommend using epoxy resins to ensure that there is effective corrosion protection in the pulp industry, energy, chemical, pharmaceutical industry, and water treatment plants.

Regional Analysis

The growing polymer industry in the Asia-Pacific region is offering a helping hand to the epoxy resin market in the region. Several leading players in the sector have opportunities to expand within the market, owing to the increasing scope.

With the technological advancements in North America, applications of epoxy resins can be made in various sectors. Innovations, moreover, have become easily achievable. This factor upholds the growth of the ecosystem in the region.

Owing to the proliferating reach of epoxy applications in the realm of painting and coating in Europe, especially for the construction and automotive industry, the size of the market under consideration is also increasing.

Leave a Comment