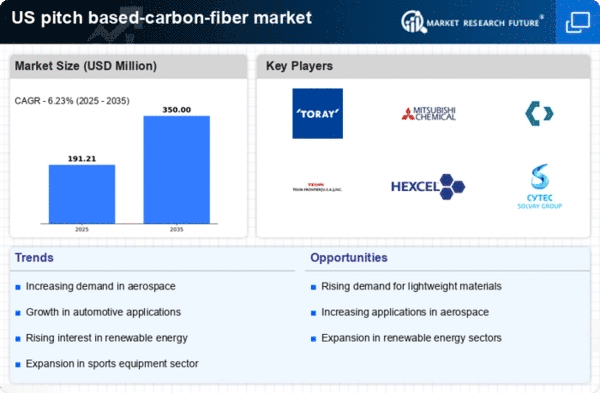

The pitch based-carbon-fiber market is currently characterized by a dynamic competitive landscape, driven by increasing demand across various sectors such as aerospace, automotive, and renewable energy. Key players are actively pursuing strategies that emphasize innovation, sustainability, and regional expansion. For instance, Toray Industries (Japan) has positioned itself as a leader through continuous investment in R&D, focusing on high-performance materials that cater to the evolving needs of its clients. Similarly, Hexcel Corporation (US) has been enhancing its operational capabilities by integrating advanced manufacturing technologies, which not only improve efficiency but also reduce environmental impact. These strategic initiatives collectively shape a competitive environment that is increasingly focused on technological advancement and sustainability.In terms of business tactics, companies are localizing manufacturing to better serve regional markets and optimize supply chains. The market structure appears moderately fragmented, with several key players exerting influence over their respective segments. This fragmentation allows for a diverse range of products and innovations, although it also necessitates that companies remain agile and responsive to market changes. The collective influence of these key players fosters a competitive atmosphere where differentiation is crucial for success.

In October Mitsubishi Chemical Corporation (Japan) announced a strategic partnership with a leading aerospace manufacturer to develop next-generation pitch based-carbon-fiber composites. This collaboration is expected to enhance the performance characteristics of aerospace components, thereby positioning Mitsubishi as a pivotal player in the aerospace supply chain. The strategic importance of this partnership lies in its potential to leverage both companies' strengths, ultimately leading to innovative solutions that meet stringent industry standards.

In September SGL Carbon (Germany) unveiled a new production facility dedicated to pitch based-carbon-fiber in the US, aimed at increasing its output capacity by 30%. This expansion reflects SGL's commitment to meeting the growing demand for lightweight materials in the automotive sector. The establishment of this facility is strategically significant as it not only enhances SGL's market presence but also aligns with the industry's shift towards more sustainable manufacturing practices.

In August Zoltek Companies (US) launched a new line of pitch based-carbon-fiber products specifically designed for wind energy applications. This move underscores Zoltek's focus on sustainability and its commitment to supporting the renewable energy sector. The introduction of these products is strategically important as it positions Zoltek to capitalize on the increasing demand for sustainable energy solutions, thereby enhancing its competitive edge in a rapidly evolving market.

As of November current competitive trends indicate a strong emphasis on digitalization, sustainability, and the integration of AI technologies within the pitch based-carbon-fiber market. Strategic alliances are increasingly shaping the landscape, allowing companies to pool resources and expertise to drive innovation. Looking ahead, competitive differentiation is likely to evolve from traditional price-based competition towards a focus on technological advancements, supply chain reliability, and sustainable practices. This shift suggests that companies that prioritize innovation and sustainability will be better positioned to thrive in the future.