Regulatory Compliance

Regulatory compliance is a significant driver for the Ultrasonic NDT Equipment Market, as industries are increasingly mandated to adhere to stringent safety and quality standards. Various sectors, including oil and gas, aerospace, and construction, are subject to regulations that require regular inspections to ensure structural integrity and safety. The implementation of standards such as ISO 9712 and ASNT SNT-TC-1A necessitates the use of reliable non-destructive testing methods, including ultrasonic testing. This compliance not only ensures safety but also mitigates risks associated with equipment failure. As a result, the demand for ultrasonic NDT equipment is expected to rise, with market analysts estimating a potential increase in market size by 20% over the next five years due to heightened regulatory scrutiny. This trend underscores the importance of the Ultrasonic NDT Equipment Market in maintaining compliance and safety across various sectors.

Technological Advancements

The Ultrasonic NDT Equipment Market is experiencing a surge in technological advancements that enhance inspection capabilities. Innovations such as phased array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD) are becoming increasingly prevalent. These technologies allow for more accurate and efficient detection of flaws in materials, which is crucial in sectors like aerospace and manufacturing. The integration of automation and artificial intelligence into ultrasonic testing equipment is also noteworthy, as it streamlines processes and reduces human error. According to recent data, the market for ultrasonic testing equipment is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next few years, driven by these advancements. This trend indicates a robust future for the Ultrasonic NDT Equipment Market as companies seek to improve quality assurance and safety standards.

Growing Awareness of Safety Standards

The growing awareness of safety standards among industries is a pivotal driver for the Ultrasonic NDT Equipment Market. As organizations recognize the critical importance of maintaining high safety and quality standards, the demand for effective non-destructive testing methods has escalated. Industries such as manufacturing, aerospace, and automotive are increasingly adopting ultrasonic testing to identify defects and ensure product reliability. This heightened awareness is reflected in the rising investments in training and certification programs for personnel involved in ultrasonic testing. Market data suggests that the ultrasonic testing segment is expected to witness a growth rate of approximately 7% annually, as companies prioritize safety and quality assurance. This trend indicates a promising outlook for the Ultrasonic NDT Equipment Market, as it aligns with the global push for enhanced safety protocols.

Rising Demand from Emerging Economies

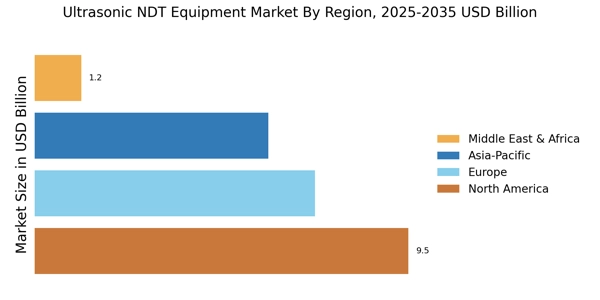

Rising demand from emerging economies is a notable driver for the Ultrasonic NDT Equipment Market. As countries in Asia, Africa, and South America continue to industrialize, there is an increasing need for advanced non-destructive testing methods to ensure product quality and safety. Industries such as construction, automotive, and energy are expanding rapidly in these regions, leading to a heightened demand for ultrasonic testing equipment. Market analysts project that the ultrasonic NDT equipment market could see a growth rate of around 8% in these emerging markets over the next few years. This growth is fueled by the need for compliance with international safety standards and the desire to enhance operational efficiency. Thus, the Ultrasonic NDT Equipment Market is poised to capitalize on the opportunities presented by these developing economies.

Increased Investment in Infrastructure

Increased investment in infrastructure development is a crucial driver for the Ultrasonic NDT Equipment Market. Governments and private sectors are allocating substantial resources to enhance transportation networks, energy facilities, and industrial plants. This investment necessitates rigorous inspection and maintenance protocols to ensure the longevity and safety of infrastructure projects. Ultrasonic NDT equipment plays a vital role in these inspections, as it allows for the detection of internal flaws without damaging the materials. Recent reports indicate that infrastructure spending is projected to rise significantly, with estimates suggesting a growth of over 15% in the next few years. This trend is likely to bolster the demand for ultrasonic testing equipment, as stakeholders seek reliable methods to assess the integrity of their investments. Consequently, the Ultrasonic NDT Equipment Market stands to benefit from this influx of infrastructure-related projects.