Growth in the Packaging Sector

The Tackifier Market is significantly influenced by the expansion of the packaging sector. With the increasing emphasis on sustainable packaging solutions, manufacturers are increasingly incorporating tackifiers into their products to enhance adhesion and performance. The packaging industry is projected to witness a growth rate of around 4.8% annually, driven by the rising demand for flexible packaging and eco-friendly materials. Tackifiers are essential in ensuring that packaging materials adhere effectively, thus improving the overall integrity and functionality of the packaging. As companies strive to meet consumer preferences for sustainable and efficient packaging solutions, the demand for tackifiers is expected to rise, further stimulating the growth of the Tackifier Market.

Expansion of End-User Industries

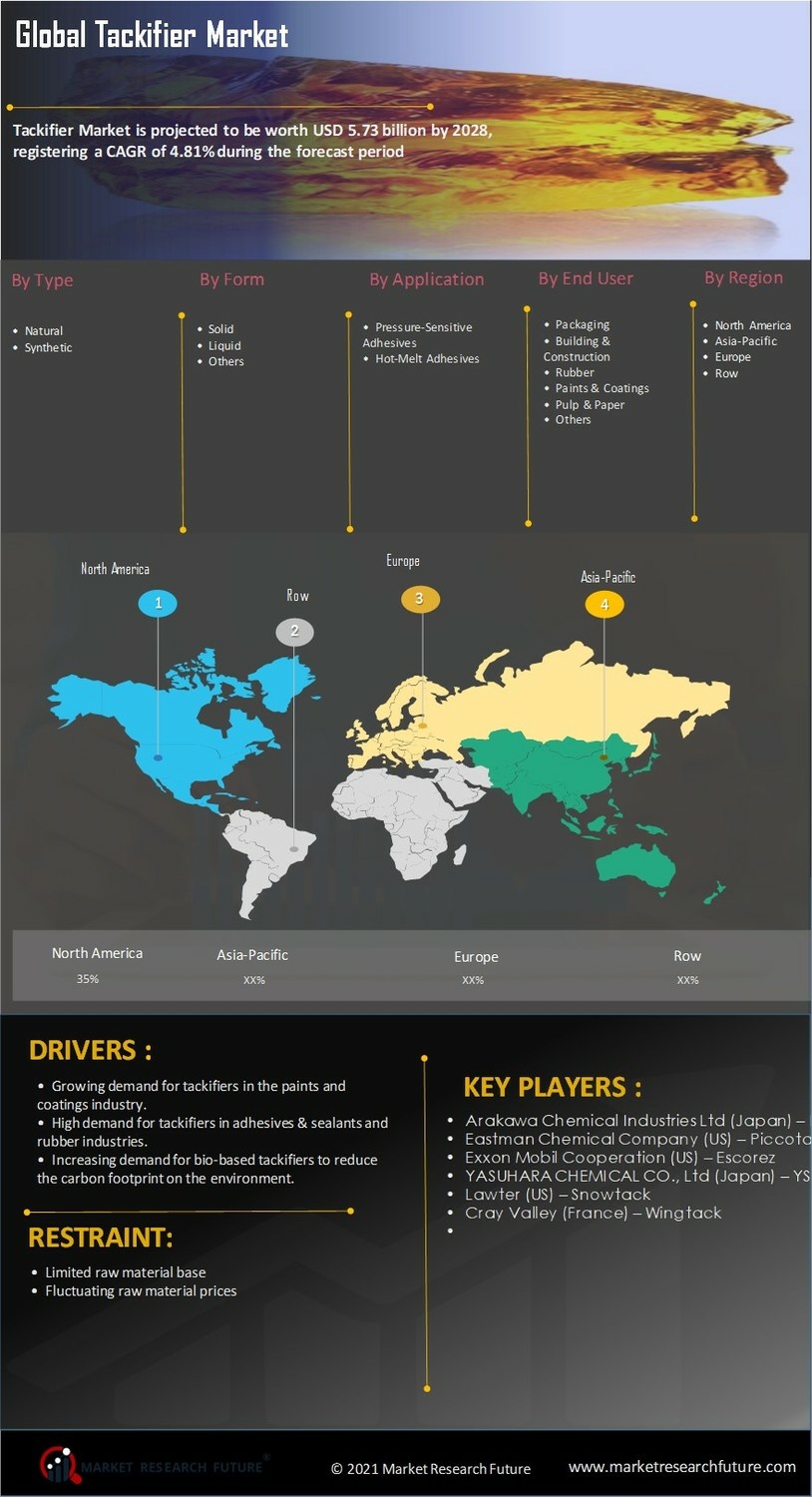

The Tackifier Market is benefiting from the expansion of various end-user industries, including automotive, construction, and textiles. As these sectors continue to grow, the demand for tackifiers is expected to rise correspondingly. For instance, the automotive industry is increasingly utilizing adhesives and sealants that require effective tackifiers to ensure durability and performance. The construction sector is also witnessing a surge in demand for adhesive solutions, driven by ongoing infrastructure projects. This expansion is projected to contribute to a compound annual growth rate of approximately 5% for the tackifier market over the next few years. As end-user industries evolve and expand, the Tackifier Market is likely to experience sustained growth, driven by the increasing need for high-performance adhesive solutions.

Rising Demand in Adhesive Applications

The Tackifier Market is experiencing a notable surge in demand, particularly within adhesive applications. This growth is driven by the increasing use of adhesives in various sectors, including automotive, construction, and packaging. For instance, the adhesive segment is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years. As industries seek to enhance product performance and durability, the need for effective tackifiers becomes paramount. Tackifiers play a crucial role in improving adhesion properties, thereby enabling manufacturers to meet stringent performance standards. Consequently, the rising demand for high-performance adhesives is likely to propel the growth of the Tackifier Market, as companies strive to innovate and develop new formulations that cater to evolving consumer needs.

Increasing Focus on Eco-Friendly Products

The Tackifier Market is witnessing a growing emphasis on eco-friendly products, driven by consumer awareness and regulatory pressures. As sustainability becomes a key consideration for manufacturers, there is a marked shift towards the use of bio-based and recyclable tackifiers. This trend is reflected in the increasing number of companies investing in research and development to create environmentally friendly alternatives. The market for bio-based tackifiers is projected to grow significantly, potentially reaching a value of USD 1 billion by 2027. This shift not only aligns with consumer preferences but also helps companies comply with stringent environmental regulations. Consequently, the focus on eco-friendly products is likely to propel the growth of the Tackifier Market, as businesses adapt to changing market dynamics.

Technological Innovations in Product Development

Technological advancements are playing a pivotal role in shaping the Tackifier Market. Innovations in polymer chemistry and formulation techniques are enabling the development of new tackifiers that offer enhanced performance characteristics. For example, the introduction of bio-based tackifiers is gaining traction, as they provide a sustainable alternative to traditional petroleum-based products. This shift towards eco-friendly solutions is likely to attract a broader customer base, particularly among environmentally conscious consumers. Furthermore, advancements in application technologies are allowing for more efficient use of tackifiers, thereby reducing waste and improving overall product performance. As a result, the ongoing technological innovations are expected to drive the growth of the Tackifier Market, as manufacturers seek to leverage these advancements to create superior products.