Polyolefins Market Summary

As per Market Research Future analysis, the Polyolefins Market Size was estimated at 256.12 USD Billion in 2024. The Polyolefins industry is projected to grow from USD 293.85 Billion in 2025 to USD 1161.17 Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 14.73% during the forecast period 2025 - 2035.

Key Market Trends & Highlights

The Polyolefins Market is currently experiencing robust growth driven by sustainability and technological advancements.

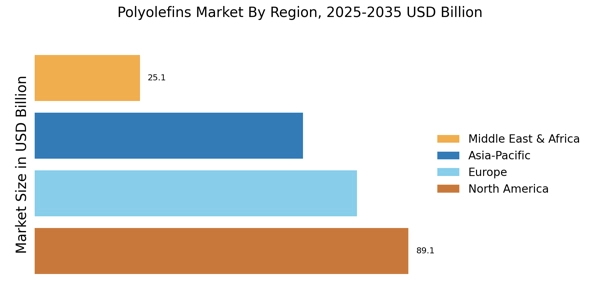

- North America remains the largest market for polyolefins, primarily due to its extensive packaging applications.

- Asia-Pacific is recognized as the fastest-growing region, fueled by increasing demand in automotive and construction sectors.

- Polyethylene continues to dominate the market as the largest segment, while polypropylene is emerging as the fastest-growing segment.

- Rising demand in the packaging sector and technological innovations in production are key drivers propelling market expansion.

Market Size & Forecast

| 2024 Market Size | 256.12 (USD Billion) |

| 2035 Market Size | 1161.17 (USD Billion) |

| CAGR (2025 - 2035) | 14.73% |

Major Players

ExxonMobil (US), LyondellBasell (US), SABIC (SA), Borealis (AT), INEOS (GB), TotalEnergies (FR), Braskem (BR), Reliance Industries (IN), Mitsui Chemicals (JP), Chevron Phillips Chemical (US)