- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

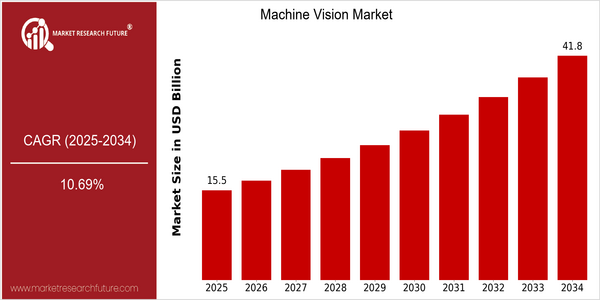

Machine Vision Market Size Snapshot

| Year | Value |

|---|---|

| 2025 | USD 15.5 Billion |

| 2034 | USD 41.8 Billion |

| CAGR (2025-2034) | 10.69 % |

Note – Market size depicts the revenue generated over the financial year

The Machine Vision market is growing steadily, with a current value of $ 15.5 billion in 2025, and a forecast value of $ 41 billion in 2034. The CAGR over the forecast period is 10.69%. The demand for automation in various industries and the development of artificial intelligence and image processing are driving this growth. As manufacturers seek to improve their production efficiency and product quality, they are increasingly adopting machine vision systems. The need for quality control in manufacturing is growing. The integration of machine vision with new technologies such as the Internet of Things and robots is also driving the market. The key players in the Machine Vision market, such as Cognex, Keyence and Siemens, are investing heavily in R & D, and establishing strategic alliances in order to gain a share of the market. These initiatives are not only strengthening their competitive position, but also contributing to the overall growth of the Machine Vision market.

Regional Deep Dive

Machine vision is experiencing rapid growth across all regions. The growth is driven by technological developments in automation and artificial intelligence, and by the increasing need for quality control in the manufacturing process. North America is characterized by a strong presence of technology companies and a booming manufacturing industry, while Europe is focusing on integrating machine vision systems into smart factories. Asia-Pacific is experiencing a high growth rate, as a result of increasing automation and quality control. The Middle East and Africa are gradually adopting machine vision, mainly due to improving infrastructure. Latin America is beginning to use machine vision to increase productivity in its manufacturing industry.

North America

- Cognex and Keyence have also been expanding their product ranges to meet the growing demand for automation.

- The new standards, especially in the automobile and electrical industry, are forcing companies to adopt vision systems for quality control and regulatory compliance.

- NVIDIA is one of the leading organizations in the field of integrating machine vision and artificial intelligence. NVIDIA is collaborating with various manufacturers to develop advanced vision systems.

Europe

- The use of machine vision systems is being encouraged by the European Union's policy of digital transformation and sustainable development. Horizon Europe is supporting innovation in this field.

- In the process of automation, companies like Siemens and Bosch have already become a leader in the use of vision to improve the efficiency and reduce the waste of their production lines.

- The regulations in Europe, especially those concerning the protection of personal data, have a great influence on the development of machine vision technology, since the introduction of such systems requires the observance of the GDPR.

Asia-Pacific

- China’s strong drive for automation is boosting the machine vision market, with domestic companies such as Hikvision and Dahua investing heavily in R&D.

- Seeing that Fanuc and Omron have become the leading companies in Japan for the automation of their factories, they are compelled to use advanced machine-vision systems in order to improve the productivity of their factories.

- The governments of countries like India, in their drive to ‘Make in India’, are encouraging the use of machine vision in various sectors.

MEA

- VISION 2021 is the national development plan for the United Arab Emirates, and it includes a program to promote technological innovation, including machine vision, to increase the country's manufacturing and industrial capabilities.

- Schneider and Siemens are actively involved in the development of such a project.

- The region’s dependence on oil and gas is encouraging diversification into new sectors. These include the use of machine vision in emerging sectors such as renewable energy.

Latin America

- Brazil's manufacturing sector is beginning to adopt machine vision for quality control, with local companies forming alliances with international suppliers.

- In Latin America the growing e-commerce business is generating a demand for automatic inspection systems in the logistics and warehousing sectors. This is resulting in increased interest in machine vision solutions.

- In order to improve productivity, the government is promoting automation and machine vision throughout the region.

Did You Know?

“With a maximum speed of up to 1,000 parts per minute, machine vision systems increase productivity considerably.” — Vision Systems Design

Segmental Market Size

The Machine Vision Market is currently growing at a rapid rate, driven by increasing automation in various industries. Artificial intelligence (AI) is gaining momentum. The machine vision market is especially important for the automobile, electrical, and pharmaceutical industries, where the integration of machine vision systems reduces the risk of human error and increases the efficiency of production.

In the field of industrial automation, machine vision has reached a point where it is no longer being tested in a pilot phase but has already been implemented in the field. North America and Europe are among the regions in which machine vision is particularly well established, primarily in the area of defect detection, robot guidance and stock control. The trend towards Industry 4.0 and the drive towards greater energy efficiency are also promoting the use of machine vision as a means of optimising production processes. Deep learning and 3D sensors are determining the evolution of this market, making it possible to develop more sophisticated and precise solutions.

Future Outlook

From 2025 to 2034, the Machine Vision Market is expected to grow at a CAGR of 10.69%. The high growth rate is attributed to the increasing automation in the manufacturing, automobile, and medical industries. Moreover, as companies look to improve efficiency and reduce costs, the integration of machine vision systems for quality control, inspection, and automation has become necessary. It is estimated that machine vision systems will be used in more than 60% of manufacturing processes by 2034, up from an estimated 37% in 2025, indicating a major shift towards automation.

Machine vision has been developing rapidly, owing to the rapid progress of its applications. The development of new and more powerful sensors, better illumination, and faster image processing are making it possible to perform increasingly complex tasks such as defect detection and preventive maintenance with greater speed and accuracy. And the growing importance of Industry 4.0 and smart factories will also create a need for highly developed machine vision systems that can be seamlessly connected to the Internet of Things and data analysis platforms. In the future, trends such as the growth of 3D machine vision and the increasing use of hyperspectral imaging will also play a key role in shaping the machine vision market and enabling a broad range of new developments and applications.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 12.1 Billion |

| Market Size Value In 2023 | USD 13.1 Billion |

| Growth Rate | 7.2% (2023-2030) |

Machine Vision Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.