Research Methodology on Linear Motion System Market

1. Introduction

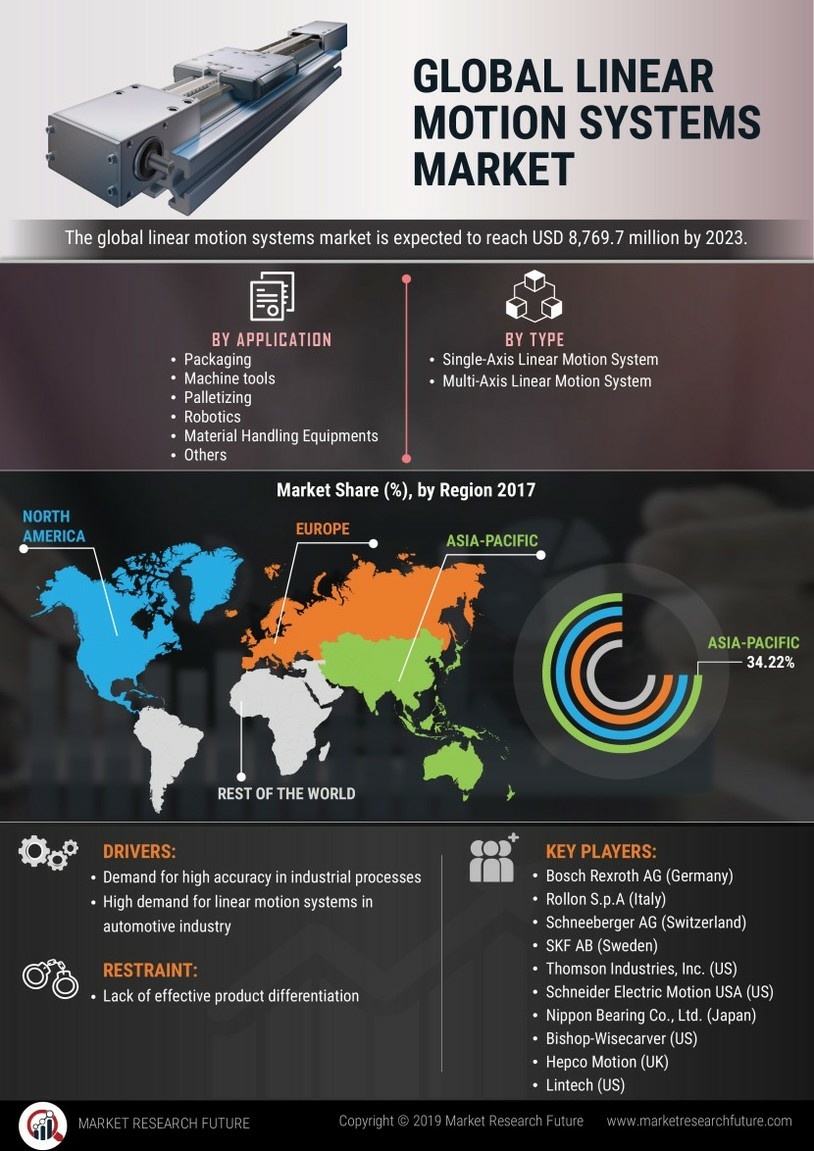

The aim of this research is to provide a comprehensive and detailed analysis of the Linear Motion System Market. Market Research Future (MRFR) uses a variety of secondary sources such as books, periodicals, press releases, company websites, and statistical databases to determine the Linear Motion System Market status, size, share, demand, sales, and industry analysis.

2. Data Collection

To gain a holistic view of the market, data is gathered from public and private industry sources, government sources, and regulatory agencies. Primary and secondary research methods are used to collect the data. Primary research consists of direct feedback from industry experts, and interviews with industry players. Secondary research gathered data from sources such as market reports, industry and trade publications, company websites, and conference proceedings.

3. Analysis

The data collected from both primary and secondary sources are analyzed using exploratory and descriptive data analysis techniques such as multiple linear regressions, correlation analysis, and principal component analysis. The primary and secondary research data is synthesized to provide an in-depth and global view of the Linear Motion System market.

4. Modelling

The data is modelled using qualitative market techniques such as SWOT analysis, PESTEL analysis, Porter’s Five Forces analysis, and factor analysis. This modelling is used to identify key industry trends, market dynamics, and opportunities, and the findings are used to develop forecasts for the Linear Motion System market.

5. Forecasting

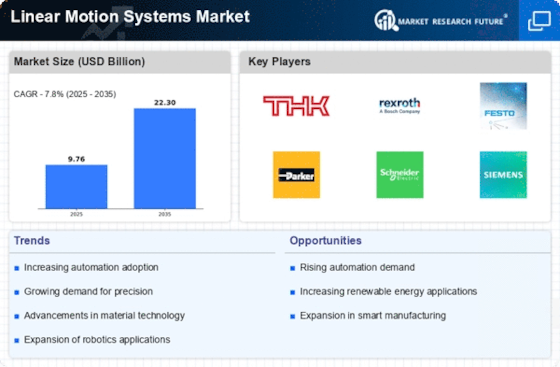

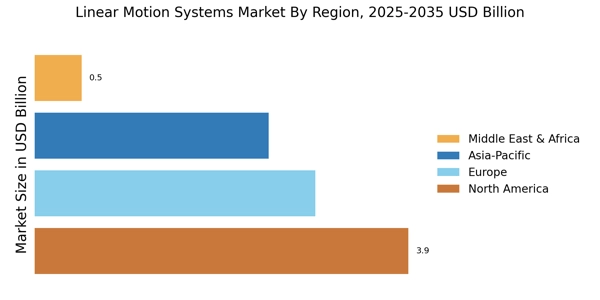

Forecasting is conducted using time series analysis, causality analysis, and linear regression methods. Each forecast model is tested against existing market data to allow for adjustments as needed and to ensure accuracy. The final forecast is developed after numerous iterations of these models.

6. Conclusion

This research report provides an in-depth and comprehensive analysis of the Linear Motion System market. Both qualitative and quantitative data are collected and analyzed to gain insights into the market. The study is based on a combination of primary and secondary research to provide a holistic view of the market. The data is analyzed using various data analysis techniques to help identify key trends, market dynamics, and industry growth opportunities. The study provides insight into the market size, share, and growth potential of the Linear Motion System market.