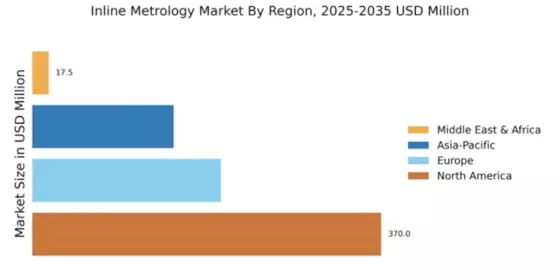

North America : Market Leader in Innovation

North America is poised to maintain its leadership in the Inline Metrology market, holding a significant share of 370.0M in 2025. The region's growth is driven by advancements in manufacturing technologies, increasing automation, and stringent quality control regulations. The demand for precision measurement tools is further fueled by the aerospace and automotive sectors, which are increasingly adopting inline metrology solutions to enhance efficiency and reduce waste. The competitive landscape in North America is robust, featuring key players such as Hexagon, Faro Technologies, and KLA Corporation. The U.S. stands out as the leading country, supported by a strong industrial base and significant investments in R&D. The presence of established companies and a growing number of startups contribute to a dynamic market environment, ensuring continuous innovation and improvement in metrology solutions.

Europe : Emerging Hub for Technology

Europe's Inline Metrology market is projected to reach 200.0M by 2025, driven by increasing demand for high-precision measurement tools across various industries. The region benefits from strong regulatory frameworks that emphasize quality assurance and compliance, particularly in the automotive and aerospace sectors. The push for Industry 4.0 and smart manufacturing is also a significant catalyst, encouraging the adoption of advanced metrology solutions. Leading countries in Europe include Germany, France, and the UK, where companies like Zeiss and Mitutoyo are prominent. The competitive landscape is characterized by a mix of established firms and innovative startups, fostering a vibrant ecosystem. The European market is also witnessing collaborations between technology providers and manufacturers to enhance product offerings and meet evolving customer needs.

Asia-Pacific : Rapidly Growing Market

The Asia-Pacific Inline Metrology market is expected to grow to 150.0M by 2025, fueled by the region's booming manufacturing sector. Countries like China, Japan, and South Korea are leading this growth, driven by increasing investments in automation and smart manufacturing technologies. The demand for inline metrology solutions is rising as manufacturers seek to improve product quality and operational efficiency, supported by favorable government policies promoting industrial modernization. China is the largest market in the region, with significant contributions from automotive and electronics industries. Key players such as Nikon Metrology and Keyence are actively expanding their presence, enhancing their product portfolios to cater to local demands. The competitive landscape is evolving, with both The Inline Metrologys share, ensuring a dynamic environment for innovation and growth.

Middle East and Africa : Emerging Market Potential

The Inline Metrology market in the Middle East and Africa is projected to reach 17.49M by 2025, reflecting the region's emerging potential in industrial applications. Growth is driven by increasing investments in infrastructure and manufacturing, particularly in countries like the UAE and South Africa. The demand for precision measurement tools is rising as industries seek to enhance quality control and operational efficiency, supported by government initiatives aimed at boosting local manufacturing capabilities. The competitive landscape is still developing, with a mix of local and international players entering the market. Companies are focusing on establishing partnerships and collaborations to enhance their service offerings. As the region continues to invest in technology and innovation, the Inline Metrology market is expected to witness significant growth in the coming years.