- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

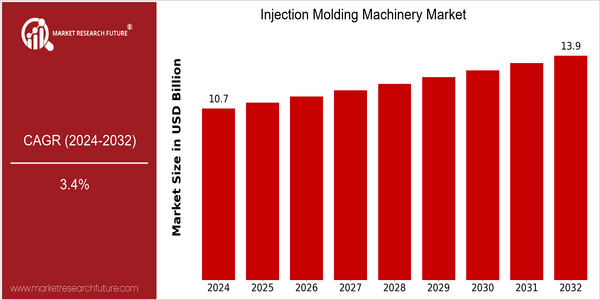

Injection Molding Machinery Market Size Snapshot

| Year | Value |

|---|---|

| 2024 | USD 10.68 Billion |

| 2032 | USD 13.95 Billion |

| CAGR (2024-2032) | 3.4 % |

Note – Market size depicts the revenue generated over the financial year

The injection molding machine market is expected to grow steadily, with a market size of $ 10.68 billion in 2024, and is expected to reach $ 13.95 billion in 2032. The compound annual growth rate (CAGR) of this market is 3.4%. The expansion of this market can be attributed to several factors, such as the increasing demand for lightweight and durable plastic components in various industries such as automobiles, household appliances, and health care. Also, the injection molding machine industry is undergoing rapid technological changes, such as the introduction of Industry 4.0 and automation, which can increase production efficiency and reduce costs. The major injection molding machine manufacturers, such as Arburg, Engel, and Husky, are constantly introducing new products and improving existing products through technological innovation and strategic cooperation. , which reflects the injection molding machine industry's shift towards energy conservation and performance optimization. This not only enhances the competitiveness of the industry, but also meets the needs of manufacturers who are trying to keep up with the trend of the times.

Regional Deep Dive

The injection molding machine industry has been growing at a fast pace in various regions, driven by the increasing demand for lightweight and durable materials in industries such as automobiles, consumer goods, and medical devices. North America is characterized by the high degree of automation and advanced manufacturing technology. Europe is characterized by a focus on energy conservation and the environment. The Asia-Pacific region is characterized by rapid industrialization and urbanization, which has led to a sharp rise in demand for injection molding machines. The Middle East and Africa are gradually adopting this technology, influenced by the development of the transport and energy industries. The injection molding machine industry in Latin America is growing due to the rise in industrial activity and foreign investment.

North America

- Among the countries with the highest market share are the United States, where companies like Husky Injection Molding and Milacron Holdings Corp. have made major investments in automation and smart manufacturing.

- Recent regulations requiring a reduction in carbon dioxide emissions are causing manufacturers to adopt energy-efficient injection molding machines. And the American Society of Mechanical Engineers, a group that promotes sustainable practices, is encouraging companies to do the same.

- Electric injection-moulding machines, such as those built by Engel and Arburg, are gaining ground.

Europe

- The European market is influenced by the Green Deal, which is intended to promote the sustainable development of the economy and has prompted companies such as KraussMaffei and Wittmann Battenfeld to develop machines that are more environmentally friendly.

- Germany has always been the leading country in injection molding. The combination of strong engineering and the introduction of Industry 4.0 has made it a major player.

- A growing demand for lightweight materials in the automobile industry is pushing the development of specialized injection molding machines. And a growing number of cooperations between automobile manufacturers and machine-building companies are bringing the companies together.

Asia-Pacific

- China has been the largest market for injection molding machinery for a long time, and is now the largest market for injection molding machinery. China's manufacturing industry is growing rapidly, and the government is promoting the development of high-tech industry with the slogan “Made in China 2025.”

- India has seen a rise in the demand for injection molding machines, due to the growing automobile and consumer goods industries. The injection molding machines are now being manufactured locally by L&T and Bharat Heavy Electricals.

- It is here that the industry is establishing itself and the investment in IoT-connected machines is increasing.

MEA

- The United Arab Emirates are investing in advanced manufacturing technology, in smart factories and automation, supported by government initiatives like the UAE Vision 2021.

- South Africa is strengthening its domestic manufacturing industry and is investing in injection moulding machines.

- The changes in the regulations for the improvement of the environment are influencing the type of machinery that is developed and used.

Latin America

- Brazil is the leading market of the South American region, where a rapidly growing automobile industry is generating strong demand for injection molding machines.

- Foreign investment in industry has increased, especially from European and American companies. This has increased the technological capacity of local industry.

- The injection molding machine market is becoming increasingly competitive as a result of the government’s recent policy changes, which aim to promote local production and reduce import tariffs.

Did You Know?

“Injection moulding is one of the most common manufacturing processes in the world, accounting for more than 30% of all plastic products.” — Plastics Industry Association

Segmental Market Size

The injection molding machinery industry plays an important role in the production of plastic components for various industries. The current market is growing steadily, driven by the growing demand for lightweight, durable materials in the automobile, consumer goods, and electronics industries. The demand for injection molding machinery is also driven by the trend towards more sustainable products, as well as by the increased performance of injection-molded parts due to advances in materials science.

The injection molding industry is now in the process of establishing a scale of business. Arburg and Engel are the leading enterprises in Europe and America. They are in the process of developing injection molding machines, which are intended for use in the production of automobile parts, medical apparatus, and packing materials. In recent years, the trend towards the use of green materials and the implementation of Industry 4.0, which includes the Internet of Things and automation, has led to a boom in the industry. In addition, the introduction of a law to reduce the waste of plastics has forced manufacturers to change their production methods and adopt more eco-friendly methods.

Future Outlook

The injection molding machine market will grow steadily from 2024 to 2032, with a projected market value of US$10.68 billion to US$13.95 billion, with a compound annual growth rate (CAGR) of 3.4%. The growth of the injection molding machine market is mainly driven by the increasing demand for lightweight and durable plastic parts in various industries such as automobiles, consumer goods, and medical equipment. In the future, as manufacturers continue to adopt new materials and new designs, the penetration rate of injection molding machines will increase. In the key industries, injection molding machines will be widely used, and the penetration rate will reach about 70 percent in 2032.

Injection moulding is expected to be a growing sector in the plastics industry, mainly driven by the implementation of Industry 4.0, automation and smart manufacturing. Also, the development of eco-friendly materials and processes will be boosted by the drive to reduce plastic waste. In addition, the trend towards electric injection moulding machines and the use of additive manufacturing will also play a crucial role in the competitive landscape and help manufacturers to meet evolving consumer demands and regulatory requirements.

Injection Molding Machinery Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.