Growing Energy Sector

The energy sector in India is experiencing substantial growth, which is likely to drive the reciprocating compressor market. With the increasing demand for energy, particularly in the industrial and commercial sectors, the need for efficient compression solutions is becoming more pronounced. The government has been investing heavily in infrastructure and energy projects, which could lead to a projected increase in the market size by approximately 15% over the next five years. This growth is expected to be fueled by the expansion of natural gas and renewable energy sources, necessitating advanced compressor technologies to ensure optimal performance. As a result, the reciprocating compressor market is poised to benefit from this upward trend in energy consumption and infrastructure development.

Industrial Automation Trends

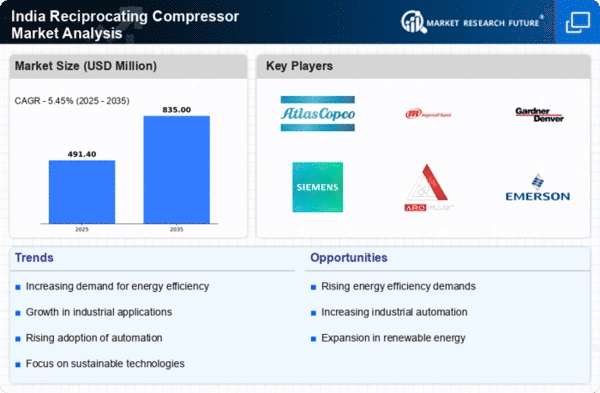

The trend towards industrial automation in India is significantly impacting the reciprocating compressor market. As industries increasingly adopt automated processes to enhance efficiency and reduce operational costs, the demand for reliable and high-performance compressors is likely to rise. Automation technologies require precise control and consistent performance, which reciprocating compressors can provide. the market is projected to grow at a CAGR of around 12% as manufacturers integrate advanced compressor systems into their automated setups. This shift not only improves productivity but also aligns with the broader goals of Industry 4.0, where smart manufacturing practices are becoming the norm. Consequently, the reciprocating compressor market is expected to thrive amid these automation advancements.

Expansion of Manufacturing Sector

India's manufacturing sector is undergoing rapid expansion, which is expected to have a positive impact on the reciprocating compressor market. The government's Make in India initiative aims to transform the country into a global manufacturing hub, leading to increased production capacities across various industries. This expansion is likely to drive the demand for reciprocating compressors, which are essential for various manufacturing processes, including refrigeration, air conditioning, and gas compression. The manufacturing sector is projected to grow at a rate of 8% annually, creating a substantial market for compressors. As industries seek to enhance their operational efficiency, the reciprocating compressor market is positioned to benefit from this manufacturing boom.

Rising Demand in HVAC Applications

The growing demand for heating, ventilation, and air conditioning (HVAC) systems in India is a key driver for the reciprocating compressor market. With urbanization and rising living standards, there is an increasing need for efficient HVAC solutions in residential, commercial, and industrial sectors. The market for HVAC systems is anticipated to expand by approximately 10% annually, which will subsequently boost the demand for reciprocating compressors, known for their reliability and efficiency in cooling applications. Furthermore, the government's initiatives to improve energy efficiency in buildings are likely to enhance the adoption of advanced compressor technologies. Thus, the reciprocating compressor market stands to gain significantly from the HVAC sector's growth.

Increased Focus on Environmental Regulations

The heightened focus on environmental regulations in India is influencing the reciprocating compressor market. As industries strive to comply with stricter emissions standards and sustainability goals, there is a growing demand for compressors that offer lower emissions and higher energy efficiency. This shift is prompting manufacturers to innovate and develop eco-friendly compressor technologies. the market is likely to shift towards compressors that utilize alternative refrigerants and energy-efficient designs, potentially increasing market growth by 7% over the next few years. Consequently, the reciprocating compressor market is adapting to these regulatory changes, positioning itself as a key player in the transition towards more sustainable industrial practices.