Rising Environmental Regulations

The Hydrostatic Transmission Market is also being shaped by rising environmental regulations aimed at reducing emissions and promoting sustainability. As governments implement stricter environmental standards, industries are compelled to adopt cleaner technologies. Hydrostatic transmissions, known for their efficiency and lower emissions, are becoming a preferred choice for many manufacturers. This shift is particularly evident in sectors such as transportation and construction, where compliance with environmental regulations is critical. The market is likely to see an increase in demand for hydrostatic systems as companies seek to align with these regulations while maintaining operational efficiency.

Expansion of Electric and Hybrid Vehicles

The Hydrostatic Transmission Market is witnessing a transformation with the expansion of electric and hybrid vehicles. As the automotive industry shifts towards electrification, hydrostatic transmissions are being integrated into these new vehicle designs to enhance performance and efficiency. These systems provide seamless power delivery and are well-suited for electric drivetrains, making them an attractive option for manufacturers. The growing trend towards sustainable transportation solutions is expected to drive the adoption of hydrostatic transmissions in electric and hybrid vehicles, potentially leading to a significant increase in market share within this segment.

Increasing Demand for Efficient Machinery

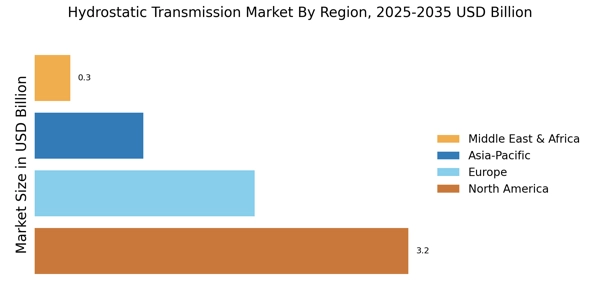

The Hydrostatic Transmission Market is experiencing a notable surge in demand for efficient machinery across various sectors, including agriculture, construction, and material handling. This demand is driven by the need for enhanced productivity and reduced operational costs. Hydrostatic transmissions offer superior efficiency compared to traditional mechanical systems, allowing for smoother operation and better fuel economy. As industries increasingly prioritize efficiency, the adoption of hydrostatic systems is likely to rise. According to recent estimates, the market for hydrostatic transmissions is projected to grow at a compound annual growth rate of approximately 5% over the next few years, indicating a robust trend towards more efficient machinery solutions.

Growth in Construction and Agricultural Sectors

The Hydrostatic Transmission Market is significantly influenced by the growth in the construction and agricultural sectors. As urbanization accelerates, the demand for construction equipment such as excavators and loaders is on the rise. Similarly, the agricultural sector is witnessing an increase in the use of tractors and harvesters equipped with hydrostatic transmissions. These systems provide the necessary torque and speed control, which are essential for modern agricultural practices. Market data suggests that the construction equipment segment alone is expected to account for a substantial share of the hydrostatic transmission market, further driving its growth in the coming years.

Technological Innovations in Hydrostatic Systems

Technological innovations are playing a crucial role in shaping the Hydrostatic Transmission Market. Advances in materials and design have led to the development of more compact and efficient hydrostatic systems. These innovations not only enhance performance but also improve reliability and reduce maintenance costs. Manufacturers are increasingly investing in research and development to create systems that can operate under extreme conditions while maintaining efficiency. The introduction of smart technologies, such as IoT integration, is also expected to revolutionize the market by providing real-time data and analytics, thereby optimizing performance and operational efficiency.