Increasing Investment in Hydrogen Infrastructure

Investment in hydrogen infrastructure is a pivotal driver for the Hydrogen Generator Market. Governments and private entities are allocating substantial funds to develop hydrogen refueling stations and production facilities. For instance, recent reports indicate that investments in hydrogen infrastructure could exceed USD 300 billion by 2030. This influx of capital is likely to facilitate the establishment of a robust supply chain, making hydrogen more accessible for various applications, including transportation and industrial processes. The expansion of infrastructure not only supports the growth of hydrogen generators but also fosters consumer confidence in hydrogen as a viable energy source.

Technological Innovations in Hydrogen Generation

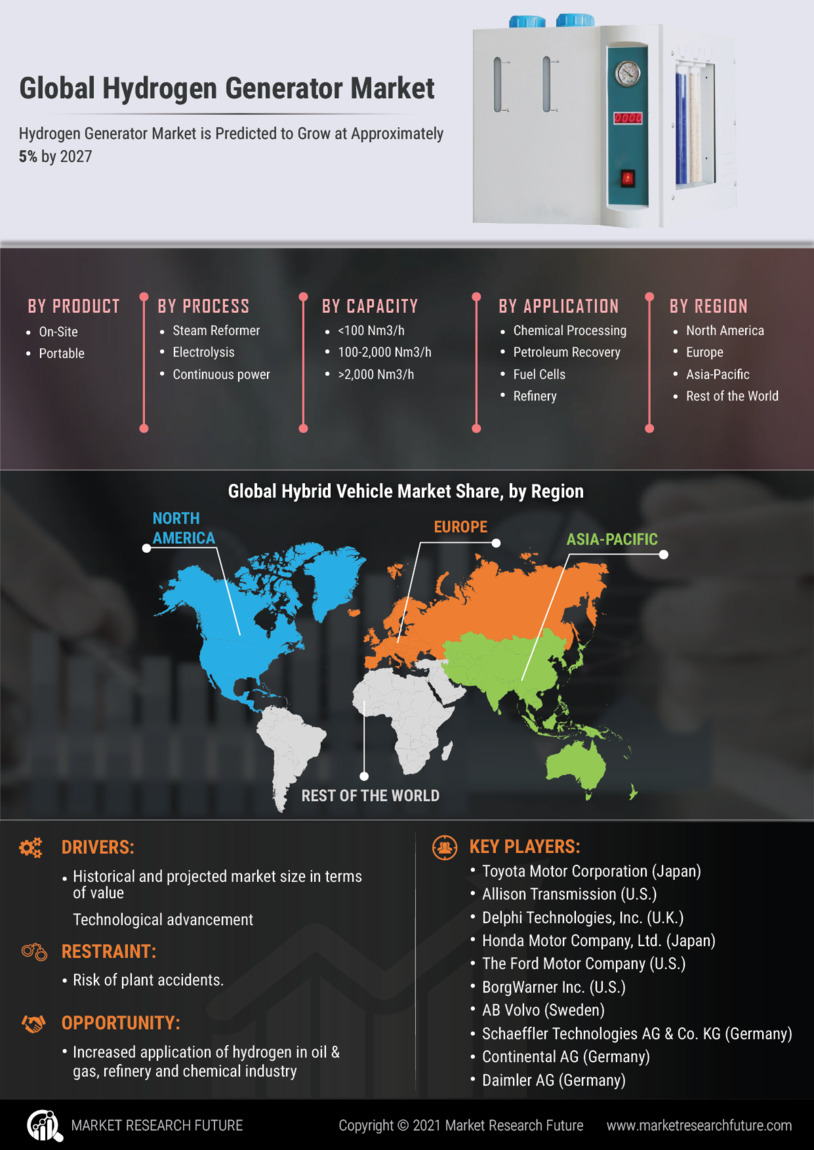

The Hydrogen Generator Market is experiencing a surge in technological innovations that enhance the efficiency and cost-effectiveness of hydrogen production. Advanced electrolysis techniques, such as proton exchange membrane (PEM) and alkaline electrolysis, are gaining traction. These methods are reported to achieve higher purity levels and lower energy consumption. Furthermore, the integration of renewable energy sources, such as solar and wind, into hydrogen generation processes is becoming increasingly prevalent. This shift not only reduces carbon emissions but also aligns with global sustainability goals. As a result, the market is projected to grow at a compound annual growth rate (CAGR) of approximately 10% over the next five years, driven by these technological advancements.

Diverse Applications of Hydrogen Across Industries

The versatility of hydrogen as an energy carrier is a crucial driver for the Hydrogen Generator Market. Hydrogen is being utilized across various sectors, including transportation, power generation, and industrial processes. In the transportation sector, hydrogen fuel cells are increasingly being adopted in vehicles, offering a clean alternative to fossil fuels. Additionally, industries such as steel manufacturing are exploring hydrogen as a means to reduce carbon emissions in their production processes. This broad applicability is likely to stimulate demand for hydrogen generators, as businesses seek to integrate hydrogen solutions into their operations.

Rising Environmental Concerns and Regulatory Pressures

The Hydrogen Generator Market is significantly influenced by rising environmental concerns and regulatory pressures aimed at reducing greenhouse gas emissions. As nations strive to meet international climate agreements, there is an increasing emphasis on transitioning to cleaner energy sources. Hydrogen, being a zero-emission fuel when combusted, presents a compelling alternative. Regulatory frameworks are evolving to support hydrogen adoption, with incentives for clean energy technologies. This shift is expected to propel the market forward, as industries seek to comply with stringent environmental regulations while also capitalizing on the benefits of hydrogen as a sustainable energy solution.

Growing Collaboration Between Public and Private Sectors

Collaboration between public and private sectors is emerging as a significant driver for the Hydrogen Generator Market. Partnerships are being formed to accelerate research and development efforts, as well as to facilitate the commercialization of hydrogen technologies. These collaborations often involve sharing resources, expertise, and funding, which can lead to innovative solutions and faster market entry. For example, joint ventures between energy companies and research institutions are focusing on developing next-generation hydrogen generation technologies. Such cooperative efforts are expected to enhance the overall growth trajectory of the hydrogen generator market, fostering a more sustainable energy landscape.