Growing Defense Expenditure

The defense sector is witnessing an increase in expenditure, which is positively impacting the high performance alloys market. Governments are investing in advanced military technologies that require materials capable of withstanding extreme conditions. High performance alloys are essential in the production of military aircraft, naval vessels, and armored vehicles, where performance and reliability are critical. The rising geopolitical tensions and the need for modernization of defense capabilities are likely to drive demand for high performance alloys. As defense budgets expand, manufacturers are expected to increase their procurement of high performance alloys to meet the stringent requirements of military applications. This trend suggests a robust growth trajectory for the high performance alloys market, as it aligns with the increasing focus on national security and defense readiness.

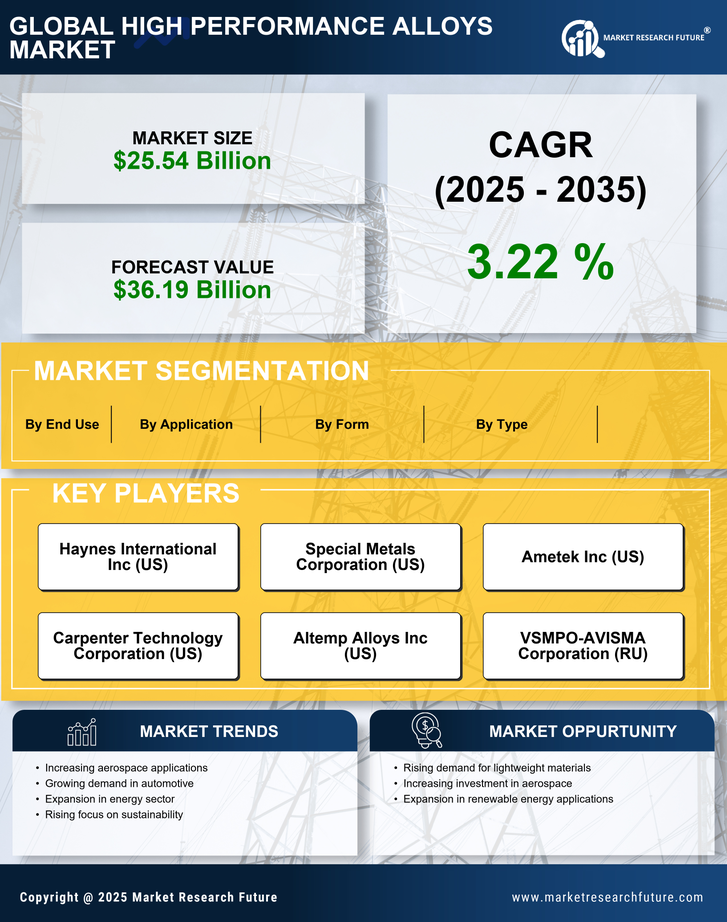

Rising Demand in Aerospace Sector

The aerospace sector is experiencing a notable surge in demand for high performance alloys, driven by the need for lightweight yet durable materials. High performance alloys market is witnessing a shift towards advanced materials that can withstand extreme temperatures and pressures. The global aerospace industry is projected to grow significantly, with an estimated increase in aircraft deliveries. This growth is likely to propel the demand for high performance alloys, as manufacturers seek materials that enhance fuel efficiency and reduce overall weight. Furthermore, the stringent regulations regarding emissions and safety standards compel aerospace manufacturers to adopt high performance alloys, which offer superior mechanical properties. As a result, the high performance alloys market is poised for substantial growth, reflecting the increasing reliance on advanced materials in aerospace applications.

Expansion in Automotive Applications

The automotive industry is increasingly adopting high performance alloys to meet the demands for enhanced performance and efficiency. High performance alloys market is benefiting from the trend towards lightweight vehicles, which are essential for improving fuel economy and reducing emissions. The automotive sector is projected to witness a compound annual growth rate, driven by innovations in electric and hybrid vehicles. These vehicles often require materials that can withstand high temperatures and provide excellent corrosion resistance, characteristics inherent in high performance alloys. Additionally, the integration of advanced manufacturing techniques, such as additive manufacturing, is likely to further boost the utilization of these alloys in automotive applications. Consequently, the high performance alloys market is expected to expand as automotive manufacturers prioritize performance and sustainability.

Increased Investment in Renewable Energy

The shift towards renewable energy sources is creating new opportunities for the high performance alloys market. As the world moves to reduce reliance on fossil fuels, there is a growing demand for materials that can withstand the harsh conditions found in renewable energy applications, such as wind turbines and solar panels. High performance alloys are particularly suited for these applications due to their strength, durability, and resistance to corrosion. The renewable energy sector is expected to see substantial investments, which will likely drive the demand for high performance alloys. This trend indicates a potential for growth in the market as manufacturers seek materials that can enhance the efficiency and longevity of renewable energy systems. Consequently, the high performance alloys market is positioned to benefit from the increasing focus on sustainable energy solutions.

Technological Innovations in Manufacturing

Technological innovations in manufacturing processes are significantly influencing the high performance alloys market. Advanced techniques such as additive manufacturing and precision casting are enabling the production of complex geometries and tailored properties in high performance alloys. These innovations not only enhance the performance characteristics of the alloys but also reduce waste and improve efficiency in production. The market for high performance alloys is projected to grow as manufacturers increasingly adopt these technologies to meet the evolving demands of various industries. Furthermore, the ability to produce customized alloys for specific applications is likely to attract a broader range of customers, thereby expanding the market. As a result, the high performance alloys market is on the cusp of transformation, driven by the integration of cutting-edge manufacturing technologies.