Increased Investment in R&D

Investment in research and development (R&D) within the machine vision market in Germany is on the rise, reflecting a commitment to innovation and technological advancement. Companies are allocating substantial resources to develop new algorithms, improve software capabilities, and enhance hardware performance. This focus on R&D is expected to yield significant advancements in machine vision technologies, potentially leading to a market valuation of over €2 billion by 2028. As organizations seek to maintain a competitive edge, the emphasis on R&D will likely drive the evolution of machine vision systems, enabling them to meet the complex demands of various industries. This trend underscores the importance of continuous improvement and adaptation in the machine vision market.

Rising Demand for Automation

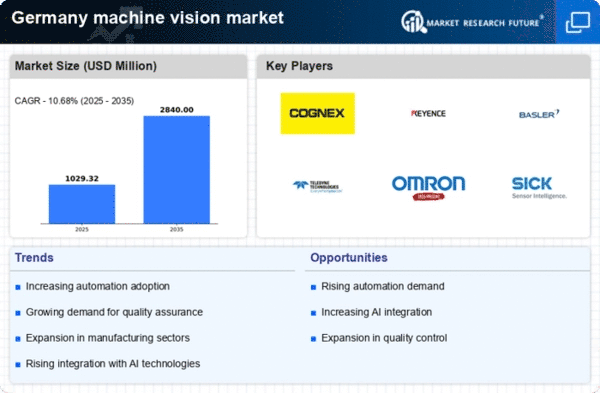

The machine vision market in Germany is experiencing a notable surge in demand for automation across various industries. This trend is driven by the need for increased efficiency and productivity in manufacturing processes. As companies strive to reduce operational costs and enhance output quality, the adoption of machine vision systems becomes essential. In 2025, the market is projected to grow at a CAGR of approximately 8.5%, reflecting the increasing reliance on automated solutions. Industries such as automotive, electronics, and pharmaceuticals are particularly focused on integrating machine vision technologies to streamline operations. This rising demand for automation not only boosts the machine vision market but also encourages innovation in technology, leading to the development of more sophisticated systems that can perform complex tasks with precision.

Expansion of Smart Manufacturing

The concept of smart manufacturing is gaining traction in Germany, significantly impacting the machine vision market. As industries transition towards Industry 4.0, the integration of machine vision systems becomes crucial for real-time monitoring and data analysis. This shift is expected to enhance operational efficiency and reduce downtime, with the machine vision market projected to reach €1.5 billion by 2027. The adoption of IoT and AI technologies in conjunction with machine vision systems is likely to create a more interconnected manufacturing environment. Consequently, this expansion of smart manufacturing not only drives the demand for machine vision solutions but also encourages the development of innovative applications that can optimize production processes.

Advancements in Imaging Technologies

Technological advancements in imaging technologies are significantly influencing the machine vision market in Germany. Innovations such as high-resolution cameras, 3D imaging, and hyperspectral imaging are enhancing the capabilities of machine vision systems. These advancements allow for more accurate inspections and analyses, which are crucial in sectors like food and beverage, where quality assurance is paramount. The integration of these advanced imaging technologies is expected to propel the market forward, with estimates suggesting a market value exceeding €1 billion by 2026. As industries increasingly recognize the benefits of these technologies, the machine vision market is likely to expand, fostering a competitive landscape that encourages further research and development.

Growing Focus on Safety and Compliance

In Germany, there is an increasing emphasis on safety and compliance regulations across various sectors, which is driving the machine vision market. Industries are adopting machine vision systems to ensure adherence to safety standards and regulatory requirements. For instance, in the automotive sector, machine vision is utilized for quality control and to prevent defects that could lead to safety hazards. This focus on safety is projected to contribute to a market growth rate of around 7% annually. As companies prioritize compliance, the demand for machine vision solutions that can provide reliable inspections and monitoring is likely to rise, further solidifying the market's position in the industrial landscape.