Market Growth Projections

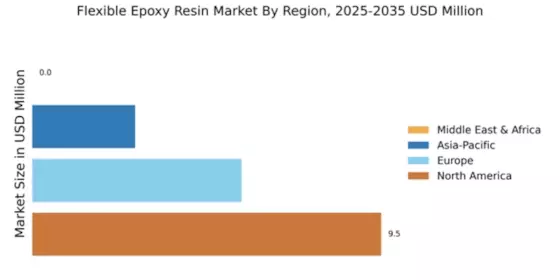

The Global Flexible Epoxy Resin Market Industry is projected to experience substantial growth, with estimates indicating a market value of 661.4 USD Million in 2024 and a remarkable increase to 1522.8 USD Million by 2035. This growth trajectory suggests a compound annual growth rate of 7.88% from 2025 to 2035, reflecting the rising demand across multiple sectors, including automotive, electronics, and construction. The increasing adoption of flexible epoxy resins in diverse applications is likely to drive innovation and investment in this market, further enhancing its potential for expansion.

Rising Demand in Automotive Sector

The Global Flexible Epoxy Resin Market Industry experiences a notable surge in demand from the automotive sector, driven by the increasing need for lightweight and durable materials. Flexible epoxy resins are utilized in various automotive applications, including adhesives, coatings, and composites, enhancing vehicle performance and fuel efficiency. As the automotive industry shifts towards electric vehicles, the demand for high-performance materials is expected to grow. This trend is reflected in the projected market value of 661.4 USD Million in 2024, with expectations to reach 1522.8 USD Million by 2035, indicating a robust growth trajectory.

Increased Focus on Sustainable Solutions

The Global Flexible Epoxy Resin Market Industry is increasingly shaped by the focus on sustainable solutions. Manufacturers are exploring bio-based and eco-friendly epoxy resins to meet the growing demand for environmentally responsible products. This shift is driven by regulatory pressures and consumer preferences for sustainable materials. As industries adopt greener practices, the flexible epoxy resin market is likely to expand, with companies investing in research to develop low-VOC and recyclable formulations. This trend not only aligns with global sustainability goals but also positions flexible epoxy resins as a viable alternative in various applications.

Technological Advancements in Material Science

The Global Flexible Epoxy Resin Market Industry is propelled by technological advancements in material science. Innovations in resin formulations and processing techniques enhance the performance characteristics of flexible epoxy resins, making them suitable for a broader range of applications. These advancements lead to improved adhesion, flexibility, and resistance to chemicals and heat. As industries seek more efficient and sustainable materials, the ongoing research and development efforts in epoxy resin technology are likely to foster market growth. This evolving landscape positions flexible epoxy resins as a preferred choice across various sectors, further solidifying their market presence.

Expansion in Electronics and Electrical Applications

The Global Flexible Epoxy Resin Market Industry is significantly influenced by the expansion of electronics and electrical applications. Flexible epoxy resins are increasingly used in the manufacturing of circuit boards, encapsulants, and potting compounds, owing to their excellent electrical insulation properties and thermal stability. The rise of consumer electronics and the demand for miniaturized components further drive this market. As a result, the industry is likely to witness a compound annual growth rate of 7.88% from 2025 to 2035, reflecting the growing reliance on flexible epoxy resins in innovative electronic solutions.

Growth in Construction and Infrastructure Development

The Global Flexible Epoxy Resin Market Industry benefits from the growth in construction and infrastructure development. Flexible epoxy resins are widely used in flooring, coatings, and adhesives, providing durability and resistance to environmental factors. As urbanization accelerates globally, the demand for high-performance construction materials increases. This trend is particularly evident in emerging economies, where infrastructure projects are on the rise. The anticipated growth in this sector contributes to the overall market expansion, with flexible epoxy resins playing a crucial role in meeting the demands of modern construction practices.