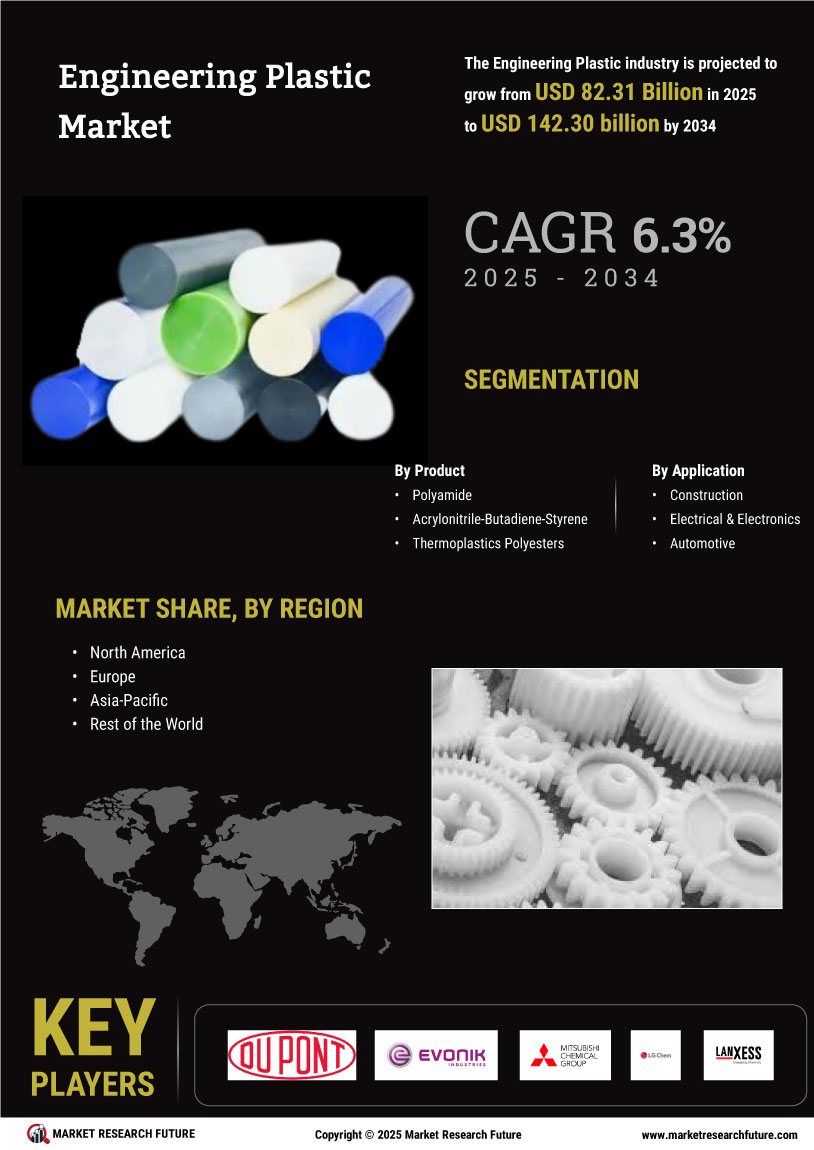

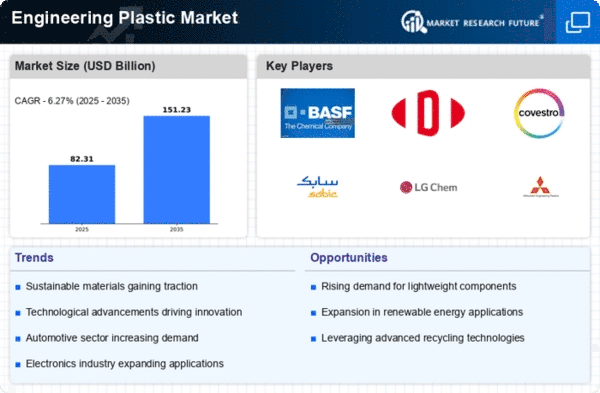

Market Growth Projections

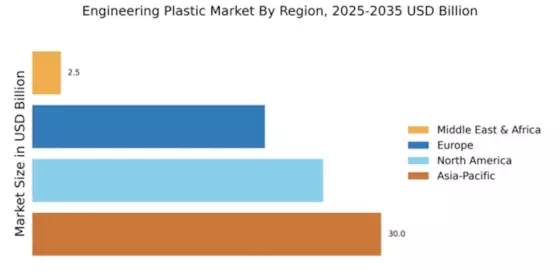

The Global Engineering Plastic Market Industry is poised for substantial growth, with projections indicating a market size of 77.5 USD Billion in 2024 and an anticipated increase to 151.3 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate of 6.27% from 2025 to 2035, reflecting the increasing adoption of engineering plastics across various sectors. The market's expansion is likely driven by factors such as technological advancements, rising demand from end-use industries, and a growing emphasis on sustainability. These dynamics collectively contribute to a robust outlook for the engineering plastics market.

Expansion of End-Use Industries

The expansion of end-use industries such as construction, healthcare, and consumer goods significantly impacts the Global Engineering Plastic Market Industry. Engineering plastics are favored for their versatility, durability, and resistance to chemicals, making them suitable for various applications. In the construction sector, materials like polyvinyl chloride (PVC) are utilized for pipes and fittings, while in healthcare, engineering plastics are employed in medical devices and equipment. This broadening of applications across industries is expected to drive market growth, with projections indicating a potential market size of 151.3 USD Billion by 2035.

Growing Focus on Sustainability

A growing focus on sustainability and environmental responsibility is reshaping the Global Engineering Plastic Market Industry. Manufacturers are increasingly adopting engineering plastics that are recyclable and have a lower environmental impact compared to traditional materials. This shift is driven by regulatory pressures and consumer preferences for eco-friendly products. As companies strive to meet sustainability goals, the demand for bio-based engineering plastics is likely to increase, further propelling market growth. The industry's commitment to sustainability may also enhance its reputation and competitiveness, positioning it favorably in the global market landscape.

Rising Demand from Automotive Sector

The Global Engineering Plastic Industry experiences a notable surge in demand from the automotive sector, driven by the need for lightweight materials that enhance fuel efficiency and reduce emissions. Engineering plastics such as polycarbonate and nylon are increasingly utilized in vehicle components, contributing to the industry's growth. In 2024, the market is projected to reach 77.5 USD Billion, with automotive applications accounting for a significant share. As manufacturers prioritize sustainability, the shift towards engineering plastics is expected to continue, potentially leading to a compound annual growth rate of 6.27% from 2025 to 2035.

Increasing Application in Electronics

The Global Engineering Plastic Market Industry benefits from the increasing application of engineering plastics in the electronics sector. With the proliferation of consumer electronics and the demand for lightweight, durable materials, engineering plastics such as acrylonitrile butadiene styrene (ABS) and polyphenylene oxide (PPO) are gaining traction. These materials offer excellent electrical insulation properties and thermal stability, making them ideal for electronic housings and components. As the electronics industry continues to evolve, the demand for engineering plastics is expected to rise, contributing to the overall market growth and potentially reaching 151.3 USD Billion by 2035.

Technological Advancements in Manufacturing

Technological advancements in manufacturing processes significantly influence the Global Engineering Plastic Market Industry. Innovations such as 3D printing and injection molding enhance the efficiency and precision of engineering plastic production. These advancements allow for the creation of complex geometries and customized solutions, catering to diverse applications across industries. As a result, the market is likely to expand, with projections indicating a growth to 151.3 USD Billion by 2035. The integration of smart manufacturing technologies may further streamline operations, reduce waste, and improve product quality, thereby reinforcing the industry's competitive edge.