Expansion in Medical Applications

The Engineered Plastics Market is experiencing a significant expansion in medical applications, driven by the increasing demand for advanced medical devices and equipment. Engineered plastics are favored in the healthcare sector due to their biocompatibility, sterilization capabilities, and ease of manufacturing. In 2025, the medical segment is projected to account for approximately 15% of the market share, as healthcare providers seek materials that ensure patient safety and product reliability. The versatility of engineered plastics allows for the production of a wide range of medical products, including surgical instruments, drug delivery systems, and diagnostic devices. As the healthcare industry continues to innovate, the reliance on engineered plastics is expected to grow, thereby contributing to the overall market growth.

Rising Demand in Automotive Sector

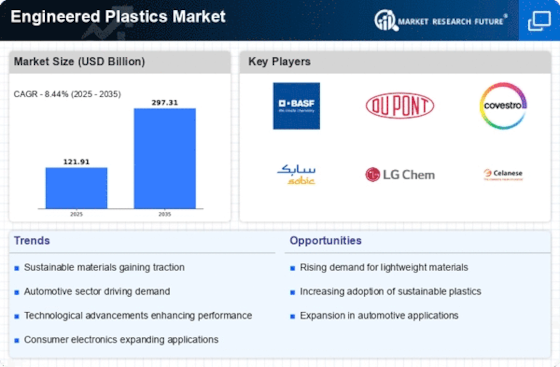

The Engineered Plastics Market is experiencing a notable surge in demand, particularly from the automotive sector. As manufacturers increasingly prioritize lightweight materials to enhance fuel efficiency and reduce emissions, engineered plastics are becoming a preferred choice. In 2025, the automotive segment is projected to account for approximately 30% of the total market share, driven by the need for durable and lightweight components. This shift not only aligns with regulatory standards but also caters to consumer preferences for eco-friendly vehicles. Furthermore, the versatility of engineered plastics allows for innovative designs, which can lead to improved performance and safety features in vehicles. As the automotive industry continues to evolve, the reliance on engineered plastics is likely to intensify, thereby propelling the market forward.

Increased Focus on Sustainable Materials

The Engineered Plastics Market is increasingly influenced by the global emphasis on sustainability and eco-friendly materials. As industries strive to reduce their carbon footprint, the demand for engineered plastics that are recyclable and made from renewable resources is on the rise. In 2025, it is estimated that sustainable engineered plastics will constitute approximately 20% of the market, reflecting a shift towards greener alternatives. Companies are investing in research and development to create bio-based engineered plastics that meet performance standards while minimizing environmental impact. This trend not only aligns with consumer expectations but also complies with stringent regulations aimed at reducing plastic waste. The growing focus on sustainability is likely to reshape the landscape of the engineered plastics market, encouraging innovation and responsible sourcing.

Growth in Electronics and Electrical Applications

The Engineered Plastics Market is witnessing substantial growth due to the increasing utilization of engineered plastics in electronics and electrical applications. With the rise of smart devices and the Internet of Things, there is a growing need for materials that offer excellent electrical insulation and thermal stability. In 2025, the electronics segment is expected to represent around 25% of the market, as manufacturers seek lightweight and durable materials for components such as housings, connectors, and circuit boards. The inherent properties of engineered plastics, such as resistance to heat and chemicals, make them ideal for these applications. As technology advances, the demand for high-performance engineered plastics in the electronics sector is anticipated to escalate, further driving the market's expansion.

Technological Innovations in Manufacturing Processes

The Engineered Plastics Market is significantly influenced by technological innovations in manufacturing processes. Advances in techniques such as 3D printing and injection molding are enhancing the efficiency and precision of engineered plastics production. In 2025, it is anticipated that these innovations will lead to a reduction in production costs by up to 15%, making engineered plastics more accessible to various industries. Furthermore, the ability to create complex geometries and customized solutions is likely to attract new applications across sectors such as aerospace, automotive, and consumer goods. As manufacturers adopt these cutting-edge technologies, the Engineered Plastics Market is expected to witness accelerated growth, driven by increased productivity and enhanced product offerings.