Regulatory Compliance

Regulatory compliance is a significant driver in the Coil Coating Market. Governments worldwide are implementing stringent regulations regarding emissions and environmental impact, compelling manufacturers to adapt their processes. Compliance with these regulations often necessitates the development of low-VOC and eco-friendly coatings, which can lead to increased operational costs. However, companies that proactively address these regulations may find new opportunities for growth. The market is expected to see a shift towards compliant products, with an estimated 30% of the market share attributed to eco-friendly coatings by 2025. This trend underscores the importance of regulatory compliance in shaping the future of the Coil Coating Market.

Technological Innovations

Technological advancements play a pivotal role in shaping the Coil Coating Market. Innovations in coating formulations and application techniques are enhancing product performance and efficiency. For instance, the introduction of advanced curing technologies has improved the durability and finish of coil coatings. Additionally, automation in the coating process is reducing production costs and increasing output. The market is expected to expand as manufacturers invest in research and development to create high-performance coatings that meet evolving industry standards. By 2025, the integration of smart technologies in the coating process could lead to a more streamlined production, potentially increasing market share for companies that embrace these innovations.

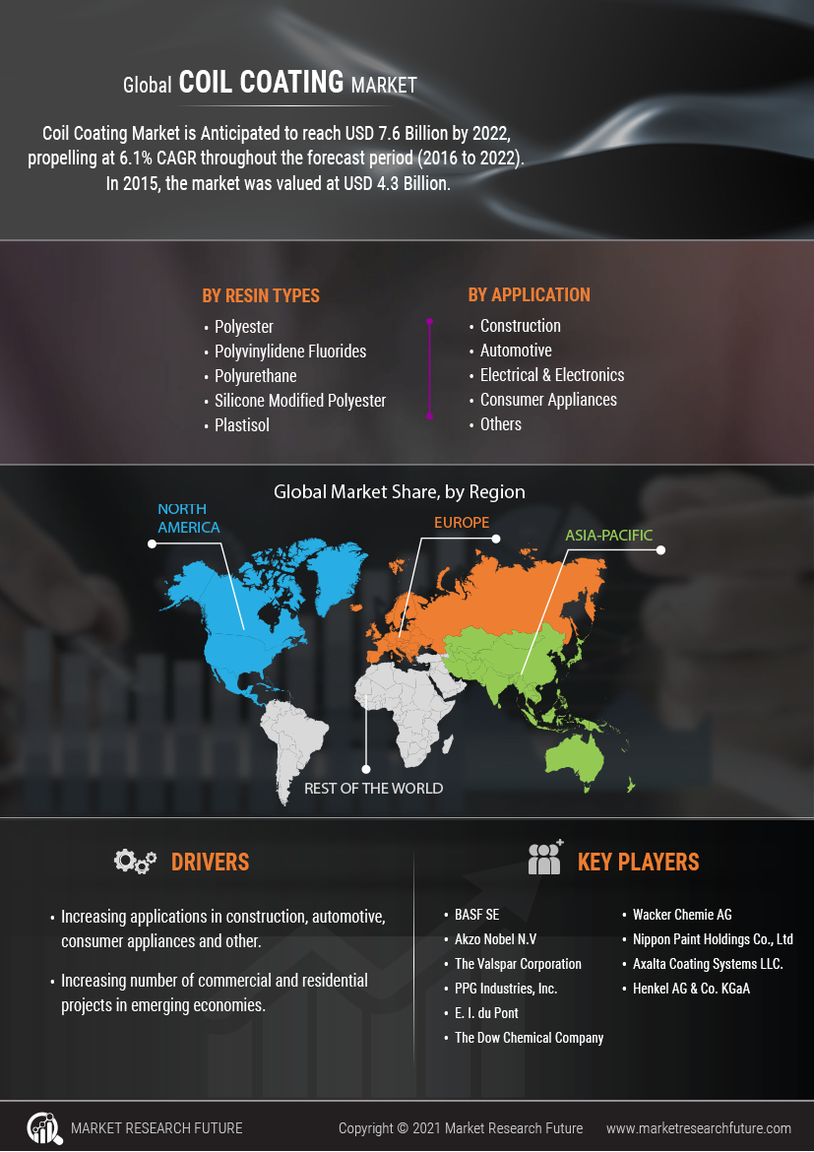

Diverse End-Use Industries

The Coil Coating Market benefits from its diverse applications across various end-use sectors. Industries such as construction, automotive, and appliances utilize coil coatings for their protective and aesthetic properties. In the construction sector, the demand for pre-painted metal products is on the rise, driven by the need for durable and visually appealing materials. The automotive industry is also witnessing a shift towards lightweight materials, where coil coatings provide corrosion resistance and enhance vehicle aesthetics. As these sectors continue to grow, the Coil Coating Market is likely to experience a corresponding increase in demand, with projections indicating a market value exceeding USD 5 billion by 2025.

Sustainability Initiatives

The Coil Coating Market is increasingly influenced by sustainability initiatives. Manufacturers are adopting eco-friendly practices, such as using water-based coatings and reducing volatile organic compounds (VOCs). This shift aligns with global environmental regulations and consumer preferences for sustainable products. As a result, the demand for coil coatings that meet these standards is rising. In 2025, the market is projected to witness a growth rate of approximately 5% annually, driven by the need for sustainable building materials. Companies that prioritize sustainability are likely to gain a competitive edge, as consumers and businesses alike are becoming more environmentally conscious. This trend not only enhances brand reputation but also opens new avenues for innovation in the Coil Coating Market.

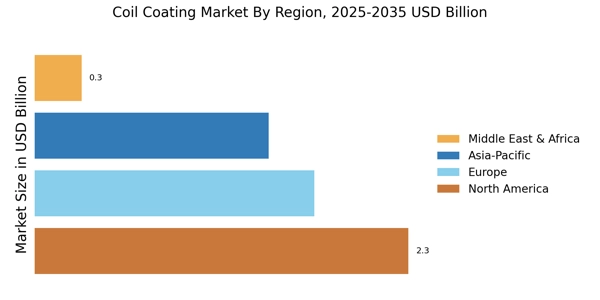

Economic Growth and Urbanization

Economic growth and urbanization are driving factors in the Coil Coating Market. As economies expand, there is a corresponding increase in construction activities, leading to higher demand for coated metal products. Urbanization trends are also contributing to this growth, as cities require more infrastructure and housing. The construction sector, in particular, is projected to grow at a rate of 4% annually, which will likely boost the demand for coil coatings. Additionally, the rise in disposable income among consumers is leading to increased spending on home improvement and appliances, further propelling the Coil Coating Market. By 2025, the market is expected to reflect these economic trends, with a notable increase in demand for high-quality coil coatings.