Expansion of the Printing Industry

The Global Coated Paper Market Industry is closely linked to the expansion of the printing industry. As print media continues to evolve, the demand for high-quality coated paper remains robust. This is particularly relevant in sectors such as advertising, publishing, and packaging, where coated paper is favored for its superior printability and finish. The resurgence of print media, coupled with the need for high-quality promotional materials, is likely to sustain demand for coated paper. The market's growth is anticipated to be bolstered by this trend, with projections indicating a potential increase to 36.1 USD Billion by 2035, reflecting the ongoing relevance of print in a digital age.

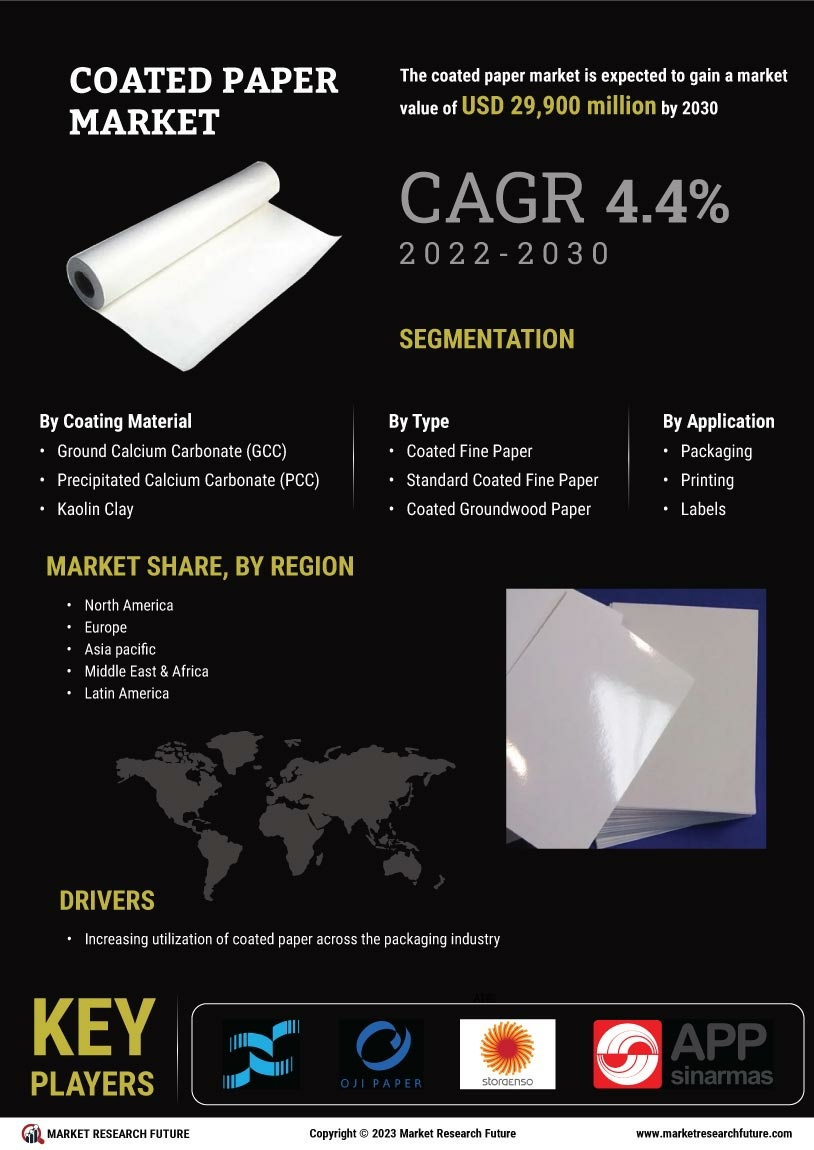

Market Trends and Growth Projections

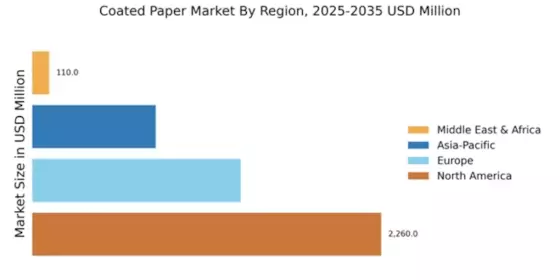

The Global Coated Paper Market Industry is characterized by dynamic trends and growth projections that reflect its evolving landscape. As the market adapts to changing consumer preferences and technological advancements, it is essential to monitor key metrics and trends. The industry is projected to grow from 22.6 USD Billion in 2024 to 36.1 USD Billion by 2035, indicating a robust growth trajectory. The compound annual growth rate of 4.34% from 2025 to 2035 suggests a steady increase in demand for coated paper across various applications. This growth is driven by factors such as sustainability, technological innovations, and the expansion of e-commerce, which collectively shape the future of the coated paper market.

Diverse Applications Across Industries

The versatility of coated paper is a key driver for the Global Coated Paper Market Industry. Coated paper finds applications in various sectors, including packaging, publishing, and stationery, due to its ability to enhance print quality and visual appeal. This diversity allows manufacturers to cater to a broad range of customer needs, from high-end packaging solutions to everyday stationery products. The adaptability of coated paper to different printing techniques and its compatibility with various substrates further enhance its market appeal. As industries continue to seek innovative packaging and printing solutions, the coated paper market is poised for growth, with expectations of reaching 22.6 USD Billion in 2024.

Growth of E-commerce and Online Retail

The surge in e-commerce and online retail is significantly impacting the Global Coated Paper Market Industry. As online shopping continues to gain traction, the demand for packaging materials, including coated paper, is on the rise. E-commerce businesses require high-quality packaging to ensure product safety during transit while also appealing to consumers visually. This trend is particularly pronounced in sectors such as electronics and fashion, where presentation plays a crucial role in customer satisfaction. The increasing reliance on coated paper for packaging solutions is expected to contribute to a compound annual growth rate of 4.34% from 2025 to 2035, further solidifying the market's position in the global economy.

Rising Demand for Sustainable Packaging

The Global Coated Paper Market Industry is experiencing a notable shift towards sustainable packaging solutions. As consumers increasingly prioritize eco-friendly products, manufacturers are adapting by utilizing coated paper that is recyclable and biodegradable. This trend is evident in various sectors, including food and beverage, where companies are opting for coated paper to enhance their brand image while minimizing environmental impact. The demand for sustainable packaging is projected to contribute significantly to the market's growth, with the industry expected to reach 22.6 USD Billion in 2024. This shift not only aligns with consumer preferences but also complies with stringent regulations aimed at reducing plastic waste.

Technological Advancements in Coating Processes

Technological innovations in coating processes are driving the Global Coated Paper Market Industry forward. Enhanced coating techniques improve the quality and performance of coated paper, making it suitable for a wider range of applications. For instance, advancements in digital printing technology allow for high-quality prints on coated paper, catering to the growing demand for customized packaging solutions. These innovations not only enhance the aesthetic appeal of products but also improve durability and functionality. As a result, the market is likely to witness a steady growth trajectory, with projections indicating a rise to 36.1 USD Billion by 2035, reflecting the industry's adaptability to evolving consumer needs.