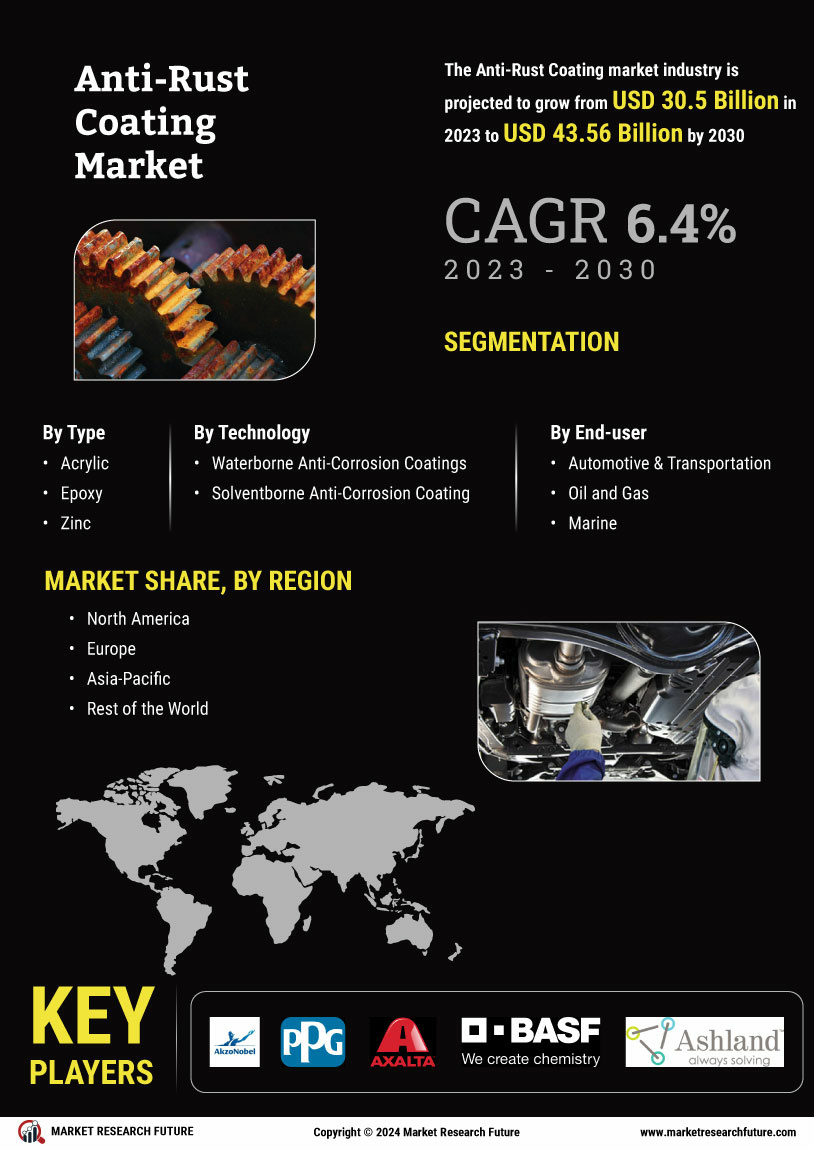

Growing Automotive Industry

The automotive sector is a significant driver for the Anti-Rust Coating Market, as manufacturers increasingly prioritize corrosion resistance in vehicle production. With the automotive industry projected to expand at a rate of around 4% annually, the demand for anti-rust coatings is anticipated to rise correspondingly. These coatings are vital for protecting vehicles from environmental factors that contribute to rust formation, thereby enhancing durability and longevity. As consumers become more aware of the importance of vehicle maintenance, the need for high-quality anti-rust coatings is likely to increase, further propelling market growth. The integration of advanced coating technologies in automotive manufacturing is also expected to contribute positively to the anti-rust coating market.

Rising Infrastructure Development

The Anti-Rust Coating Market is experiencing a surge due to the increasing investments in infrastructure development across various regions. Governments and private sectors are allocating substantial budgets for the construction and maintenance of roads, bridges, and buildings. This trend is likely to drive the demand for anti-rust coatings, as these materials are essential for protecting structures from corrosion. According to recent data, the construction sector is projected to grow at a compound annual growth rate of approximately 5% over the next few years. This growth is expected to create a robust market for anti-rust coatings, as they play a critical role in extending the lifespan of infrastructure projects and reducing maintenance costs.

Environmental Regulations and Standards

The Anti-Rust Coating Market is significantly influenced by stringent environmental regulations aimed at reducing the use of harmful substances in coatings. Governments are implementing policies that encourage the adoption of eco-friendly anti-rust coatings, which are less harmful to the environment. This shift towards sustainable practices is likely to drive innovation in the market, as manufacturers develop new formulations that comply with these regulations. The increasing emphasis on sustainability is expected to create opportunities for growth, as companies seek to differentiate their products in a competitive landscape. As a result, the demand for environmentally friendly anti-rust coatings is projected to rise, aligning with global trends towards sustainability.

Expansion of Marine and Oil & Gas Sectors

The marine and oil & gas industries are pivotal to the growth of the Anti-Rust Coating Market, as these sectors require robust protective coatings to combat corrosion in harsh environments. The demand for anti-rust coatings in marine applications is driven by the need to protect vessels and offshore structures from saltwater corrosion. Similarly, the oil and gas sector relies on these coatings to safeguard pipelines and equipment from environmental degradation. With the oil and gas industry expected to witness a resurgence in exploration and production activities, the demand for anti-rust coatings is likely to increase. This trend presents a significant opportunity for manufacturers to cater to the specific needs of these industries.

Technological Innovations in Coating Solutions

Technological advancements are reshaping the Anti-Rust Coating Market, as new innovations lead to the development of more effective and durable coating solutions. The introduction of advanced materials and application techniques is enhancing the performance of anti-rust coatings, making them more appealing to various industries. For instance, the emergence of nanotechnology in coatings is expected to improve corrosion resistance and reduce the overall weight of coatings. As industries seek to improve efficiency and reduce costs, the adoption of these innovative solutions is likely to accelerate. The continuous evolution of coating technologies is anticipated to drive market growth, as companies strive to meet the increasing demands for high-performance anti-rust coatings.