North America : Market Leader in Coatings

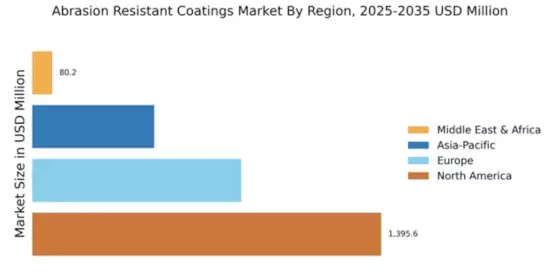

North America continues to lead the Abrasion Resistant Coatings market, holding a significant share of 1395.62 million in 2024. The growth is driven by increasing demand from industries such as automotive, aerospace, and construction, where durability and protection are paramount. Regulatory support for advanced materials and sustainability initiatives further catalyze market expansion, ensuring compliance with environmental standards. The competitive landscape is robust, featuring key players like PPG Industries, Sherwin-Williams, and AkzoNobel. The U.S. stands out as a major contributor, leveraging technological advancements and innovation in coating formulations. The presence of established manufacturers and a strong distribution network enhances market accessibility, positioning North America as a hub for high-performance coatings.

Europe : Emerging Market Dynamics

Europe's Abrasion Resistant Coatings market is valued at 835.44 million, reflecting a growing trend towards innovative and sustainable solutions. The region benefits from stringent regulations promoting eco-friendly products, which drive manufacturers to invest in R&D for advanced coatings. The automotive and industrial sectors are key demand drivers, as companies seek to enhance product longevity and performance while adhering to environmental standards. Leading countries like Germany, France, and the UK are at the forefront, with major players such as BASF and Hempel driving competition. The market is characterized by a mix of established firms and emerging startups, fostering a dynamic environment for innovation. Collaborative efforts between industry and academia further enhance the region's competitive edge in developing cutting-edge coating technologies.

Asia-Pacific : Rapid Growth and Adoption

The Asia-Pacific region, with a market size of 487.81 million, is witnessing rapid growth in the Abrasion Resistant Coatings sector. This surge is attributed to the booming construction and automotive industries, particularly in countries like China and India. Increasing urbanization and infrastructure development are key demand drivers, alongside a growing awareness of the benefits of high-performance coatings in enhancing product durability and lifespan. China leads the market, supported by significant investments in manufacturing and technology. Key players such as Nippon Paint and Kansai Paint are expanding their presence, focusing on innovation and sustainability. The competitive landscape is evolving, with local manufacturers gaining traction alongside global giants, creating a vibrant market environment that fosters growth and development.

Middle East and Africa : Untapped Market Potential

The Middle East and Africa region, valued at 80.19 million, presents significant growth opportunities in the Abrasion Resistant Coatings market. The demand is primarily driven by the oil and gas sector, where protective coatings are essential for equipment longevity in harsh environments. Additionally, the construction industry is expanding, leading to increased requirements for durable coatings that can withstand extreme conditions. Countries like the UAE and South Africa are emerging as key players in this market, with a growing number of local manufacturers entering the space. The competitive landscape is characterized by a mix of international and regional companies, fostering innovation and adaptation to local market needs. As infrastructure projects increase, the demand for high-quality coatings is expected to rise, positioning the region for future growth.