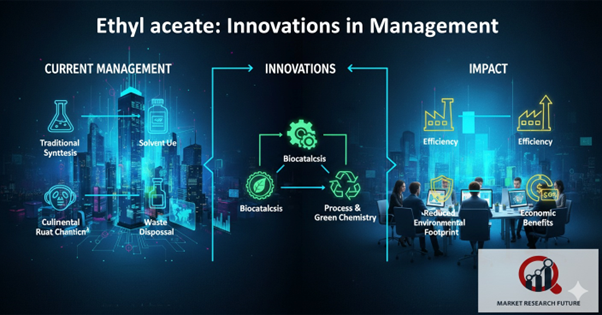

Ethyl acetate: Innovations in Management

The Introduction to the Ethyl Acetate Market

With the growing applications of ethyl acetate in the painting and coating industry, the demand for the chemical is expected to proliferate through the forecast period at an impressive CAGR of 9%. The size of the global ethyl acetate market is projected to change from USD 3.44 billion in 2024 to USD 8.88 billion by 2035.

Ethyl acetate is an organic compound that is a liquid at room temperature and pressure. It is widely used in paints, lacquers, varnishes, soft drinks, and other applications. Its growth is attributed to its low cost, versatility across industries, and broad global distribution channels.

The oil and gas industry, which accounts for more than 40% of ethyl acetate demand, is forecast to grow at a slower pace over the coming years, as companies focus more on improving production efficiency in existing fields rather than expanding output.

Regional Production and Market Trends

China dominates global ethyl acetate production, historically accounting for about one-third of worldwide supply. Other Asian countries contribute an additional 70%, benefiting from competitive pricing and availability.

The United States produces over 34% of global ethyl acetate, though the industry is fragmented between smaller producers (under 100,000 tons annually) and larger producers (over 100,000 tons annually).

Despite recent flooding disruptions, the US market is expected to grow due to technological innovations and expanded industrial usage. Europe and Central Asia collectively account for 24% of global production, driven by increased adoption across consumer and industrial applications.

The Middle East and Africa are expected to see slower growth due to price stability and supply constraints, but producers are increasingly shifting focus toward ethyl acetate as a preservative and industrial solvent.

Applications and Practical Insights

Ethyl acetate is not only a solvent but also an extraction agent, helping release substances from liquids. Its boiling properties make it useful in educational and laboratory demonstrations, such as generating steam in controlled experiments.

By applying heat and manipulating air pressure, ethyl acetate can be made to evaporate rapidly, demonstrating fundamental chemical principles. This versatility underscores its industrial significance and broad applicability.

Regional Analysis

The ethyl acetate market shows strong regional variation. The Asia-Pacific region, led by China and India, dominates due to large-scale chemical manufacturing, lower production costs, and export capabilities.

North America is growing steadily, with the US focusing on advanced production techniques and diversified applications in paints, coatings, and pharmaceuticals. Europe maintains a significant market share through stringent quality standards and consistent demand across industrial sectors.

Latin America, particularly Brazil, benefits from ethanol availability for ethyl acetate production, supporting both fuel and industrial markets.

The Middle East and Africa face slower growth, constrained by price fluctuations and limited industrial capacity, though demand is gradually increasing in sectors like food preservation, pharmaceuticals, and coatings.

Overall, global demand continues to expand, driven by industrialization, chemical innovation, and regional production efficiencies.

Leave a Comment