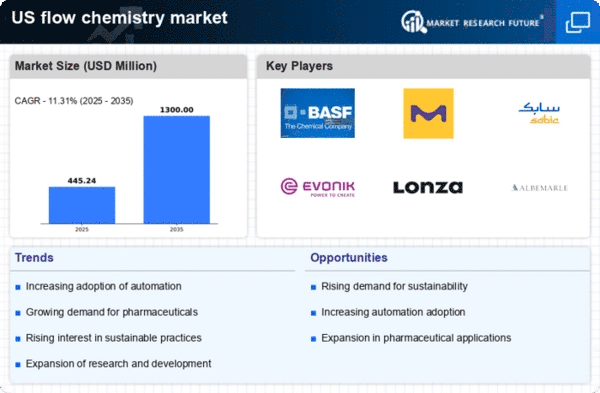

The flow chemistry market is currently characterized by a dynamic competitive landscape, driven by innovation, sustainability, and the increasing demand for efficient chemical processes. Key players such as Albemarle Corporation (US), BASF SE (DE), and Merck KGaA (DE) are actively shaping the market through strategic initiatives. Albemarle Corporation (US) focuses on enhancing its production capabilities and expanding its product portfolio, particularly in lithium and specialty chemicals, which are integral to flow chemistry applications. Meanwhile, BASF SE (DE) emphasizes digital transformation and sustainability, aiming to reduce its carbon footprint while optimizing its manufacturing processes. Merck KGaA (DE) is also investing in research and development to innovate its flow chemistry solutions, thereby reinforcing its competitive positioning.The business tactics employed by these companies include localizing manufacturing and optimizing supply chains to enhance operational efficiency. The market structure appears moderately fragmented, with several players vying for market share. However, the collective influence of major companies like Albemarle, BASF, and Merck suggests a trend towards consolidation, as these firms leverage their resources to gain competitive advantages.

In October Albemarle Corporation (US) announced a strategic partnership with a leading technology firm to develop advanced flow chemistry systems aimed at improving production efficiency. This collaboration is expected to enhance Albemarle's capabilities in producing high-performance materials, thereby positioning the company favorably in the market. The strategic importance of this partnership lies in its potential to accelerate innovation and streamline operations, which are critical in a rapidly evolving industry.

In September BASF SE (DE) launched a new line of sustainable flow chemistry products designed to meet the growing demand for environmentally friendly solutions. This initiative not only aligns with global sustainability goals but also strengthens BASF's market presence by appealing to eco-conscious consumers. The launch signifies a strategic pivot towards sustainability, which is increasingly becoming a key differentiator in the chemical industry.

In August Merck KGaA (DE) expanded its flow chemistry research facilities in the US, investing approximately €50 million in state-of-the-art technology. This expansion is indicative of Merck's commitment to enhancing its R&D capabilities and fostering innovation in flow chemistry applications. The investment is likely to yield significant advancements in product development, further solidifying Merck's competitive edge.

As of November current trends in the flow chemistry market include a pronounced shift towards digitalization, sustainability, and the integration of AI technologies. Strategic alliances are increasingly shaping the competitive landscape, enabling companies to pool resources and expertise. Looking ahead, competitive differentiation is expected to evolve, with a greater emphasis on innovation and technology rather than solely on price. The ability to ensure supply chain reliability while delivering cutting-edge solutions will likely become paramount in maintaining a competitive advantage.