Technological Advancements in 3D Printing

The 3D printed medical implants market is experiencing a surge due to rapid technological advancements in 3D printing techniques. Innovations such as bioprinting and the use of advanced materials are enhancing the precision and functionality of medical implants. For instance, the introduction of new polymers and bio-ceramics is enabling the production of implants that closely mimic natural bone properties. This not only improves patient outcomes but also reduces the risk of complications. The UK is witnessing a growing number of research initiatives aimed at integrating artificial intelligence with 3D printing, which could further streamline the design and manufacturing processes. As a result, the market is projected to grow at a CAGR of approximately 25% over the next five years, indicating a robust demand for advanced medical solutions.

Cost-Effectiveness of 3D Printing Technology

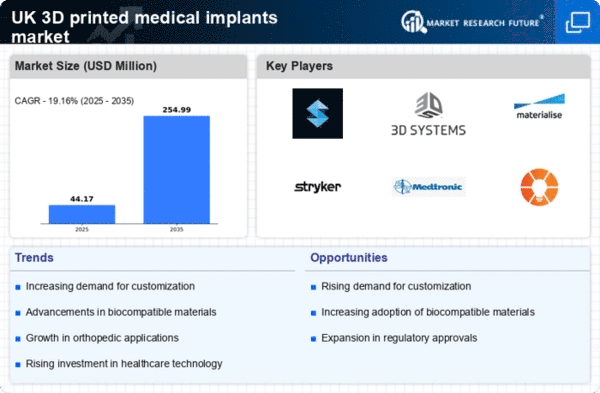

Cost considerations are playing a pivotal role in the growth of the 3d printed-medical-implants market. The ability to produce implants on-demand reduces inventory costs and minimizes waste, making 3D printing a financially attractive option for healthcare providers. In the UK, hospitals are increasingly recognizing the potential for cost savings associated with 3D printed implants, particularly in elective surgeries where customization is essential. The reduction in manufacturing time and the ability to create complex designs without the need for extensive tooling further enhance the economic viability of this technology. As healthcare budgets tighten, the demand for cost-effective solutions is likely to drive the adoption of 3D printing in the medical field, potentially leading to a market growth rate of 20% over the next few years.

Rising Incidence of Orthopedic and Dental Procedures

The 3d printed-medical-implants market is being propelled by the rising incidence of orthopedic and dental procedures in the UK. As the population ages, the demand for joint replacements and dental implants is increasing. According to recent statistics, the number of hip and knee replacement surgeries has risen by over 15% in the last five years. This trend is creating a substantial market for 3D printed implants, which offer advantages such as reduced surgery time and improved fit. Furthermore, the ability to produce complex geometries with 3D printing allows for the creation of implants that are more effective in addressing specific medical conditions. Consequently, the market is likely to expand as healthcare providers seek innovative solutions to meet the growing surgical demands.

Increasing Demand for Personalized Healthcare Solutions

The shift towards personalized healthcare is significantly influencing the 3d printed-medical-implants market. Patients are increasingly seeking customized solutions that cater to their unique anatomical needs. This trend is driven by the growing awareness of the benefits of tailored medical implants, which can lead to improved surgical outcomes and faster recovery times. In the UK, healthcare providers are beginning to adopt 3D printing technologies to create bespoke implants, which are designed based on individual patient scans. This customization not only enhances patient satisfaction but also reduces the likelihood of implant rejection. The market is expected to see a substantial increase in demand for personalized implants, with projections indicating a potential market size of £1 billion by 2030.

Enhanced Collaboration Between Healthcare and Technology Sectors

The collaboration between the healthcare and technology sectors is fostering innovation within the 3d printed-medical-implants market. Partnerships between hospitals, universities, and tech companies are leading to the development of cutting-edge 3D printing solutions tailored for medical applications. In the UK, initiatives aimed at bridging the gap between medical professionals and engineers are becoming more prevalent, resulting in the creation of advanced prototypes and clinical trials for new implant designs. This collaborative approach not only accelerates the development of new products but also ensures that they meet the specific needs of patients and healthcare providers. As these partnerships continue to grow, the market is expected to benefit from a steady influx of innovative solutions, potentially enhancing its overall growth trajectory.