Growth in Consumer Electronics

The Polyoxymethylene Market is also witnessing significant growth driven by the consumer electronics sector. With the increasing proliferation of electronic devices, manufacturers are seeking materials that offer durability and precision. Polyoxymethylene Market, known for its excellent mechanical properties and resistance to wear, is being utilized in various applications, including connectors, switches, and housings. Market data indicates that the consumer electronics segment is projected to contribute approximately 25% to the overall polyoxymethylene market by 2025. This trend is further supported by the rising consumer demand for high-quality electronic products, which necessitates the use of advanced materials like polyoxymethylene to ensure longevity and performance.

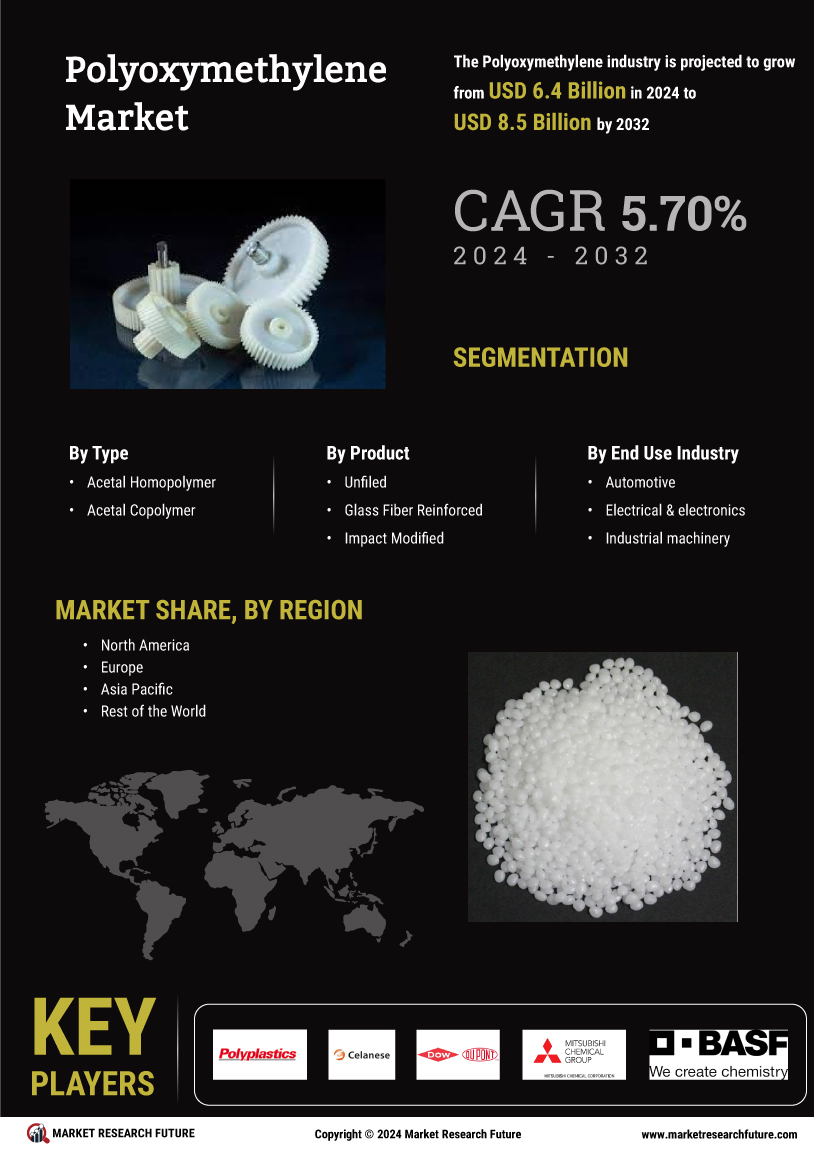

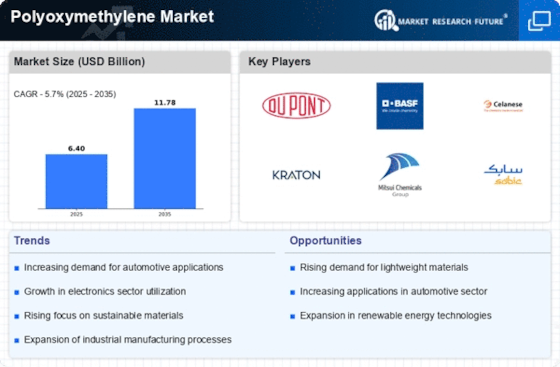

Rising Demand in Automotive Sector

The Polyoxymethylene Market is experiencing a notable surge in demand, particularly from the automotive sector. This increase is largely attributed to the material's superior properties, such as high strength, low friction, and excellent dimensional stability. As automotive manufacturers strive to enhance fuel efficiency and reduce emissions, the lightweight characteristics of polyoxymethylene make it an attractive option for various components, including fuel systems and interior parts. Recent estimates suggest that the automotive segment could account for over 30% of the total polyoxymethylene consumption by 2025, indicating a robust growth trajectory. Furthermore, the ongoing shift towards electric vehicles is likely to further bolster the demand for polyoxymethylene, as these vehicles require advanced materials that can withstand higher performance standards.

Innovations in Manufacturing Processes

Innovations in manufacturing processes are playing a pivotal role in shaping the Polyoxymethylene Market. Advances in production techniques, such as injection molding and extrusion, have enhanced the efficiency and scalability of polyoxymethylene production. These innovations not only reduce production costs but also improve the material's properties, making it more appealing for various applications. As manufacturers adopt these advanced processes, the availability of high-quality polyoxymethylene is expected to increase, thereby driving market growth. Furthermore, the integration of automation and smart technologies in manufacturing is likely to streamline operations, leading to a more competitive landscape within the polyoxymethylene market.

Expanding Applications in Industrial Sectors

The Polyoxymethylene Market is witnessing an expansion of applications across various industrial sectors. Industries such as aerospace, healthcare, and machinery are increasingly recognizing the benefits of polyoxymethylene due to its excellent mechanical properties and chemical resistance. For instance, in the aerospace sector, polyoxymethylene is utilized for components that require high precision and durability. Market projections indicate that the industrial applications segment could account for nearly 20% of the total polyoxymethylene market by 2025. This diversification of applications is likely to drive demand, as industries seek materials that can meet stringent performance requirements while also offering cost-effectiveness.

Regulatory Support for Sustainable Materials

The Polyoxymethylene Market is benefiting from increasing regulatory support aimed at promoting sustainable materials. Governments and regulatory bodies are implementing policies that encourage the use of eco-friendly materials in various industries, including automotive and consumer goods. This shift towards sustainability is prompting manufacturers to explore polyoxymethylene as a viable alternative to traditional materials, given its recyclability and lower environmental impact. Market analysts suggest that the regulatory landscape will continue to evolve, potentially leading to a rise in polyoxymethylene adoption across multiple sectors. This trend not only aligns with global sustainability goals but also positions polyoxymethylene as a key player in the transition towards greener manufacturing practices.