- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

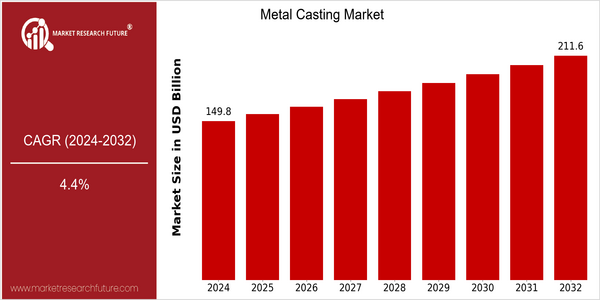

Metal Casting Market Size Snapshot

| Year | Value |

|---|---|

| 2024 | USD 149.8 Billion |

| 2032 | USD 211.6 Billion |

| CAGR (2024-2032) | 4.4 % |

Note – Market size depicts the revenue generated over the financial year

Metal Casting Market The global metal casting market is projected to reach USD 149.8 billion in 2024 and is expected to reach USD 211.6 billion by 2032. The compound annual growth rate (CAGR) for this market is 4.4% from 2024 to 2032. This market growth is mainly driven by the following factors: The increasing demand for lightweight and durable materials in the automotive and aerospace industries. The increasing use of 3D printing and automation in casting processes. The increasing use of magnesium, copper, and aluminum in the production of electric vehicles. Technological advancements are playing a significant role in driving the metal casting market. The development of high-performance alloys and the use of green casting methods is a significant improvement in product quality and safety. GE and Alcoa are leading the way in the field of research and development. Strategic initiatives, such as mergers and acquisitions, are expected to increase production capabilities and market share.

Regional Deep Dive

The Castings Market is growing dynamically in different regions, driven by the increasing demand for metal castings from the automobile, aerospace and construction industries. North America is characterized by the adoption of advanced manufacturing technology and a strong focus on the environment, while Europe is characterized by the importance of regulatory compliance and the development of new materials. The Asia-Pacific region is experiencing rapid industrialization and urbanization, resulting in a growing demand for metal castings. The Middle East and Africa are characterized by large investments in energy and construction projects, while Latin America is gradually gaining momentum in its manufacturing industry, driven by economic recovery.

North America

- The introduction of additive manufacturing processes has reshaped the cast iron industry, with GE Additive at the forefront of combining 3D printing with casting techniques.

- The American Foundry Society, which was established in 1899, is a society whose members are foundries.

- The industry is undergoing a revolution. The shift from internal-combustion engines to electric motors has sparked a demand for lightweight components, and Ford and Tesla have been investing in advanced casting techniques to meet new design requirements.

Europe

- The European Union’s Green Deal is driving foundries to change towards more sustainable practices, with funding for projects aimed at reducing their impact on the environment, such as those undertaken by the European Foundry Association.

- In Germany the aluminum-casting industry has been a success. It is now the most widely used method of reducing the weight of automobiles, and Audi and BMW are putting up state-of-the-art casting plants.

- Circular economy is gaining importance in the metal industry. In particular, the growing use of slag in the smelting industry is the result of the circular economy. The European Association of the Metal Recycling Industry (EARPI) and the European Association of Foundries (EVS) are working together to promote sustainable development.

Asia-Pacific

- China is still the world's leading manufacturer of cast iron, and the number of smart manufacturing companies is still growing.

- India’s growing automobile and aeronautics industries are boosting the demand for precision castings, while the Make in India initiative is encouraging local manufacturing.

- This region is experiencing a high demand for light materials, especially in the automobile industry. The companies are experimenting with new casting methods to increase the fuel efficiency of their cars.

MEA

- The UAE is investing heavily in the construction of its national road network. This is driving the demand for casting products, and companies such as Emirates Global Aluminium are leading the way in the development of new casting techniques.

- Saudi Arabia's Vision 2030 plan has brought an increase in investment in the cast-iron sector in order to support local manufacturing.

- The regulation of the metal-casting industry is developing with the aim of reducing waste and increasing the recovery of the material.

Latin America

- Brazil's automobile industry is regaining its footing, which has meant a rise in the demand for cast iron. As a result, companies such as Fiat and Volkswagen have been investing in local foundries.

- Nearby the American market, Mexico is becoming a center of metal casting, and companies like Nemak are expanding their plants in order to supply the automobile industry of North America.

- Government programs to develop the manufacturing industry encourage investment in new casting technology. The goal is to improve the skills of the workforce and the quality of the equipment.

Did You Know?

“Casting is one of the oldest of all manufacturing processes, dating back 5,000 years to the time of the Mesopotamians and the Egyptians.” — American Foundry Society

Segmental Market Size

The metal casting market is experiencing a steady growth owing to the growing demand for lightweight and durable material from various industries, such as the automobile, aeronautical and construction industries. The rising demand for energy-efficient vehicles has led to an increase in the use of advanced metal casting technology. The need for stringent regulations aimed at reducing emissions has also bolstered the market. In addition, the introduction of new casting processes such as 3D printing and automation is improving the efficiency and quality of production.

At present, the adoption of new metal casting techniques is at the stage of large-scale application, and General Electric and Ford are the leading companies in integrating these innovations into their manufacturing processes. The most important uses of metal casting are in the making of engine components, structural parts, and complex components for consumer products. There are also significant trends that are driving the growth of the industry: the use of sustainable and eco-friendly materials and the promotion of greener practices. Also, new CAD and simulation software are influencing the evolution of metal casting, which makes for more precise and efficient methods of production.

Future Outlook

From 2024 to 2032, the market value of the metal casting market is expected to increase from 149.8 billion to 211.1 billion, with a compound annual growth rate (CAGR) of 4.4%. This growth is mainly due to the rising demand for automobiles, aviation and construction equipment, where the performance and longevity of the equipment depend on the use of metal parts. The use of lightweight materials and complex shapes in industrial products is expected to lead to a further increase in the demand for metal castings, as well as the use of advanced casting techniques, such as 3D printing and precision casting, to reduce the cost of products and reduce the loss of products.

A key technological development and supportive policies will be crucial to the future of the metal casting industry. Materials science, particularly the development of high-performance alloys and eco-friendly casting processes, is expected to meet the requirements of manufacturers while ensuring that they comply with increasingly stringent regulations. The growing emphasis on sustainable development and the circular economy will also increase the use of recycled metals in the casting process, thereby improving resource efficiency. As a result, the metal casting industry is expected to see a shift towards more sustainable practices, with up to 30% of the total share of the market being supplied by recycled metals by 2032.

In the field of casting, too, the trend toward automation and digitalization of manufacturing processes is reshaping the scene. Industry 4.0 and the Internet of Things will be used to provide real-time monitoring and to support predictive maintenance. The result will be shorter production cycles and fewer unplanned interruptions. As companies seek to improve their efficiency and product quality, the metal casting industry is likely to experience a marked increase in investment, which will in turn drive innovation and competitiveness. In short, the outlook for the metal casting industry is good. The focus will be on technology and sustainability.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 345.5billion Billion |

| Market Size Value In 2023 | USD 372.44 Billion |

| Growth Rate | 7.80% (2022-2030) |

Metal Casting Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.