Growing Awareness of Water Scarcity

The increasing awareness of water scarcity issues in Japan is driving the ceramic membranes market. As the population grows and water resources become strained, there is a heightened focus on sustainable water management practices. Ceramic membranes offer an effective solution for recycling and reusing water, making them attractive to both municipal and industrial users. This trend is underscored by government initiatives promoting water conservation and the adoption of advanced treatment technologies. The market is likely to see a surge in demand, with estimates suggesting a potential increase in market size by 15% over the next decade as more entities recognize the value of ceramic membranes in addressing water scarcity.

Increasing Environmental Regulations

The ceramic membranes market in Japan is experiencing growth due to stringent environmental regulations aimed at reducing water pollution and promoting sustainable practices. The Japanese government has implemented various policies that mandate the treatment of wastewater before discharge, thereby increasing the demand for effective filtration solutions. Ceramic membranes, known for their durability and efficiency, are becoming a preferred choice in industries such as food and beverage, pharmaceuticals, and chemical processing. As a result, the market is projected to expand, with an estimated growth rate of 8% annually over the next five years. This regulatory landscape encourages industries to invest in advanced filtration technologies, further driving the ceramic membranes market.

Investment in Research and Development

Investment in research and development (R&D) is a key driver for the ceramic membranes market in Japan. Companies are increasingly allocating resources to innovate and enhance membrane technologies, aiming to improve efficiency and reduce costs. This focus on R&D is crucial as it leads to the development of membranes with superior performance characteristics, such as higher flux rates and greater resistance to fouling. The Japanese government also supports R&D initiatives through funding and partnerships with academic institutions, fostering an environment conducive to innovation. As a result, the ceramic membranes market is expected to grow, with projections indicating a market value increase of approximately $300 million by 2028.

Technological Innovations in Filtration

Technological advancements in filtration processes are playing a crucial role in shaping the ceramic membranes market. Innovations such as the development of new materials and improved membrane designs enhance the performance and efficiency of ceramic membranes. These advancements allow for better separation processes, leading to higher purity levels in treated water. In Japan, research institutions and companies are collaborating to create next-generation membranes that can withstand extreme conditions, thereby expanding their applicability across various sectors. The market is expected to benefit from these innovations, with an anticipated increase in market value reaching $500 million by 2027.

Rising Industrialization and Urbanization

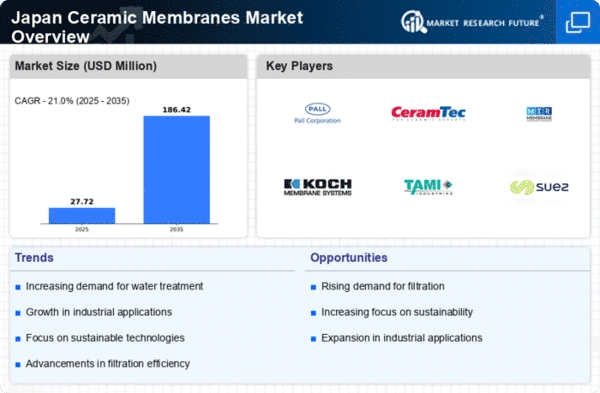

Japan's rapid industrialization and urbanization are significantly impacting the ceramic membranes market. As cities expand and industries proliferate, the demand for clean water and efficient wastewater treatment solutions is escalating. The industrial sector, particularly in manufacturing and energy, is increasingly adopting ceramic membranes for their superior filtration capabilities. This trend is reflected in the market data, which indicates that the industrial segment accounts for approximately 60% of the total market share. The need for reliable and sustainable water management solutions is likely to propel the ceramic membranes market forward, with projections suggesting a compound annual growth rate (CAGR) of 7% through 2030.