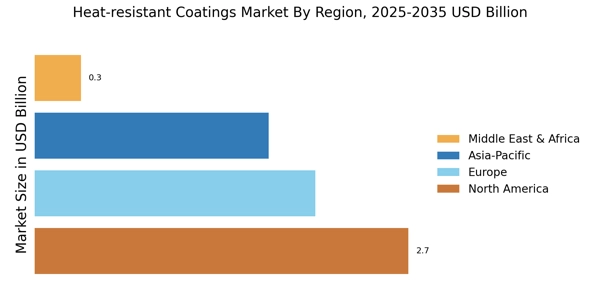

By region, the study provides market insights into North America, Europe, Asia-Pacific, and the Rest of the World. The Asia-Pacific region has a significant and growing population, and as a result, there is increasing demand for a range of products and services, including automotive, construction, and industrial goods. The use of heat-resistant coatings is expected to grow in this region due to the increasing demand for high-performance coatings that can withstand high temperatures and harsh environments in various industries.

Moreover, the increasing investments in infrastructure development and construction activities in countries such as China and India are expected to drive the growth of the heat-resistant coatings market in the region. The growth of the automotive industry in the region is also expected to drive demand for heat-resistant coatings, as the industry requires high-performance coatings for engine components, exhaust systems, and other parts that are exposed to high temperatures.

Further, the major countries studied in the market report are The U.S., Canada, Germany, France, the UK, Italy, Spain, China, Japan, India, Australia, South Korea, and Brazil

Europe’s Heat-resistant Coatings market accounts for the third-largest market share. Europe has a large number of industries where heat-resistant coatings are essential, including automotive, aerospace, construction, and others. In addition, the region has a strong emphasis on research and development, and many European companies are actively engaged in developing advanced heat-resistant coatings that can meet the growing demand from various industries. The market for heat-resistant coatings in Europe is also driven by various regulations and standards that require high-performance coatings to ensure the safety and reliability of various products and applications.

For example, the automotive industry in Europe has strict emission standards that require high-performance coatings for exhaust systems, catalytic converters, and other components. Further, the Germany Heat-resistant Coatings market held the largest market share, and the UK Heat-resistant Coatings market was the fastest-growing market in the European region.

North America, Heat-resistant Coatings market, is expected to grow at the fastest CAGR from 2023 to 2030. The market for heat-resistant coatings in North America is driven by various factors, including the growth of end-user industries such as automotive, aerospace, and construction, which require high-performance coatings that can withstand high temperatures and provide long-lasting protection. In addition, the region has a strong focus on research and development, and many companies in North America are actively engaged in developing advanced coatings that can meet the growing demand from various industries.

The regulatory environment in North America is also a significant driver of the heat-resistant coatings market, as various regulations and standards require high-performance coatings to ensure the safety and reliability of various products and applications. For example, the Environmental Protection Agency (EPA) in the United States has strict emission standards for the automotive industry that require high-performance coatings for exhaust systems, catalytic converters, and other components. Moreover, the U.S. Heat-resistant Coatings market held the largest market share, and the Canada Heat-resistant Coatings market was the fastest-growing market in the North American region.