Regulatory Support and Frameworks

The regulatory landscape in Germany is evolving to support the growth of the 3d printed-medical-implants market. The Federal Institute for Drugs and Medical Devices (BfArM) has established guidelines that facilitate the approval process for 3D printed implants, ensuring safety and efficacy. This supportive regulatory framework encourages innovation and investment in the sector. Furthermore, the European Union's Medical Device Regulation (MDR) is also influencing the market by setting high standards for quality and safety. As a result, manufacturers are more inclined to invest in research and development, which could lead to a broader range of products in the 3d printed-medical-implants market. The anticipated increase in product offerings may enhance competition and drive down costs, benefiting healthcare providers and patients alike.

Technological Advancements in 3D Printing

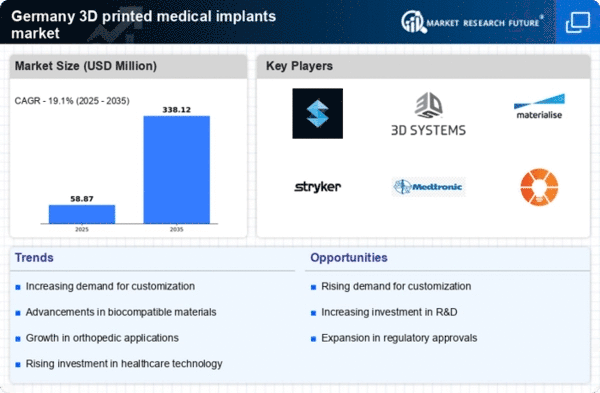

The 3d printed-medical-implants market is experiencing a surge due to rapid technological advancements in 3D printing techniques. Innovations such as selective laser sintering and fused deposition modeling are enhancing the precision and efficiency of implant production. In Germany, the integration of artificial intelligence and machine learning in design processes is streamlining the customization of implants, catering to individual patient needs. This technological evolution is expected to drive market growth, with projections indicating a compound annual growth rate (CAGR) of approximately 25% over the next five years. As hospitals and clinics increasingly adopt these technologies, the demand for tailored medical solutions is likely to rise, further propelling the 3d printed-medical-implants market forward.

Collaboration Between Academia and Industry

The collaboration between academic institutions and industry players is fostering innovation within the 3d printed-medical-implants market. In Germany, universities and research centers are partnering with medical device manufacturers to develop cutting-edge materials and technologies. These collaborations are essential for advancing research in biocompatible materials and improving the functionality of 3D printed implants. Such partnerships not only enhance the knowledge base but also facilitate the transfer of technology from research to practical applications. As a result, the market is likely to benefit from a steady influx of innovative products and solutions. The increasing number of joint research initiatives is expected to contribute to a projected growth rate of 20% in the 3d printed-medical-implants market over the next few years, indicating a robust future for this sector.

Increased Investment in Healthcare Infrastructure

Germany's commitment to enhancing its healthcare infrastructure is a crucial driver for the 3d printed-medical-implants market. The government has allocated substantial funding towards modernizing healthcare facilities and integrating advanced technologies. This investment is likely to facilitate the adoption of 3D printing technologies in hospitals and clinics, enabling the production of high-quality medical implants on-site. As healthcare providers upgrade their capabilities, the demand for 3D printed implants is expected to rise. Reports suggest that healthcare spending in Germany could reach €500 billion by 2026, with a significant portion directed towards innovative medical technologies. This financial commitment is anticipated to bolster the 3d printed-medical-implants market, fostering an environment conducive to growth and innovation.

Rising Demand for Personalized Healthcare Solutions

The shift towards personalized healthcare is significantly impacting the 3d printed-medical-implants market. Patients are increasingly seeking customized solutions that cater to their unique anatomical and physiological needs. In Germany, this trend is reflected in the growing number of orthopedic and dental implants being tailored to individual specifications. The market is projected to grow as healthcare providers recognize the benefits of personalized implants, which can lead to improved patient outcomes and satisfaction. According to recent estimates, the demand for personalized medical solutions is expected to increase by 30% in the coming years, thereby driving the expansion of the 3d printed-medical-implants market. This focus on customization not only enhances the patient experience but also positions manufacturers to innovate and differentiate their offerings.