Growing Aging Population

The demographic shift towards an aging population in the GCC is a crucial driver for the 3d printed-medical-implants market. As the elderly population increases, so does the prevalence of chronic conditions that often require surgical interventions and implants. This demographic trend is expected to escalate the demand for customized and effective medical solutions, particularly in orthopedics and dental applications. By 2030, it is estimated that the proportion of individuals aged 65 and older in the GCC will rise significantly, thereby increasing the need for innovative medical implants. The 3d printed-medical-implants market is poised to address these needs through tailored solutions that enhance the quality of life for older patients.

Rising Demand for Customized Solutions

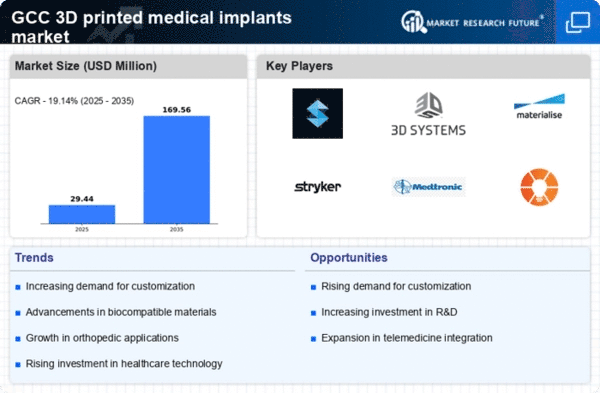

The 3d printed-medical-implants market is significantly influenced by the rising demand for customized medical solutions. Patients increasingly seek implants that are tailored to their specific anatomical requirements, which traditional manufacturing methods struggle to provide. The ability to create bespoke implants through 3D printing not only enhances patient satisfaction but also improves recovery times and overall health outcomes. In the GCC, the market for customized implants is expected to grow at a CAGR of around 20% over the next five years, reflecting a shift towards personalized healthcare. This trend is further supported by advancements in imaging technologies that facilitate precise modeling of individual patient anatomy.

Technological Advancements in 3D Printing

The 3d printed-medical-implants market is experiencing rapid growth due to continuous technological advancements in 3D printing techniques. Innovations such as bioprinting and the development of new materials, including bio-compatible polymers and metals, are enhancing the quality and functionality of medical implants. These advancements allow for the production of complex geometries that are tailored to individual patient needs, thereby improving surgical outcomes. In the GCC region, the adoption of these technologies is projected to increase, with the market expected to reach approximately $1.5 billion by 2026. This growth is driven by the increasing demand for personalized medical solutions and the ability to produce implants that integrate seamlessly with human tissue.

Enhanced Surgical Precision and Efficiency

The 3d printed-medical-implants market is also driven by the enhanced surgical precision and efficiency that 3D printing technologies offer. Surgeons can utilize patient-specific models created through 3D printing to plan and execute procedures with greater accuracy. This capability reduces operation times and minimizes the risk of complications, which is particularly valuable in complex surgeries. In the GCC, hospitals are increasingly adopting these technologies to improve surgical outcomes and patient safety. The integration of 3D printed implants into surgical practices is expected to grow, with a projected increase in market share as healthcare providers recognize the benefits of precision medicine.

Increased Investment in Healthcare Infrastructure

The 3d printed-medical-implants market is benefiting from increased investment in healthcare infrastructure across the GCC. Governments in the region are prioritizing healthcare development, leading to enhanced facilities and the integration of advanced technologies. This investment is likely to foster an environment conducive to the adoption of 3D printing technologies in medical applications. As healthcare facilities upgrade their capabilities, the demand for innovative solutions such as 3D printed implants is expected to rise. Reports indicate that healthcare spending in the GCC is projected to exceed $100 billion by 2026, creating a robust market for advanced medical technologies, including 3D printed implants.