Technological Advancements in 3D Printing

The 3d printed-medical-implants market is experiencing a surge due to rapid technological advancements in 3D printing techniques. Innovations such as bioprinting and the use of advanced materials are enhancing the precision and functionality of medical implants. In France, the integration of artificial intelligence and machine learning in the design process is streamlining production, thereby reducing costs and lead times. This technological evolution is expected to drive market growth, with projections indicating a potential increase in market value by 15% annually. As healthcare providers seek more effective solutions, the demand for customized implants tailored to individual patient needs is likely to rise, further propelling the 3d printed-medical-implants market forward.

Regulatory Framework Supporting Innovation

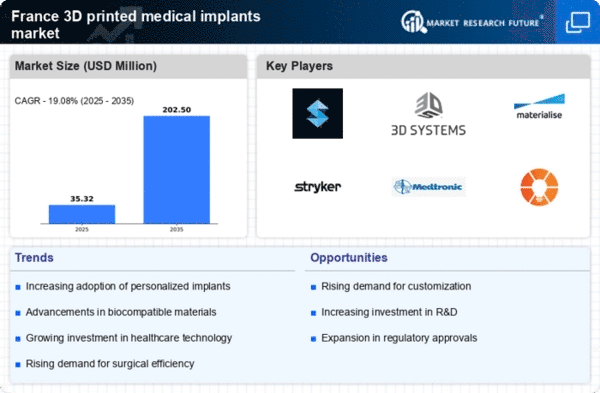

The regulatory framework in France is evolving to support innovation within the 3d printed-medical-implants market. Authorities are increasingly recognizing the potential of 3D printing technologies to enhance patient care and are streamlining approval processes for new medical devices. This supportive environment encourages manufacturers to invest in research and development, leading to the introduction of novel implant designs. With the regulatory landscape becoming more favorable, the market is expected to witness a growth rate of around 18% in the coming years. This trend suggests that as regulations adapt to technological advancements, the 3d printed-medical-implants market will likely flourish, fostering a culture of innovation.

Increased Investment in Healthcare Infrastructure

Investment in healthcare infrastructure in France is a crucial driver for the 3d printed-medical-implants market. The French government has been allocating substantial funds to enhance medical facilities and technology, which includes the adoption of 3D printing technologies. This investment is expected to facilitate the integration of advanced manufacturing processes in hospitals and clinics, thereby improving patient outcomes. With an estimated increase in healthcare spending by 10% over the next few years, the 3d printed-medical-implants market stands to benefit significantly. Enhanced infrastructure will likely enable faster production and deployment of innovative medical implants, meeting the rising demand for advanced healthcare solutions.

Growing Awareness of Advanced Medical Technologies

The growing awareness of advanced medical technologies among healthcare professionals and patients is propelling the 3d printed-medical-implants market. Educational initiatives and workshops are increasingly highlighting the benefits of 3D printing in creating complex and customized implants. In France, this heightened awareness is fostering a more informed patient base that actively seeks out innovative treatment options. As a result, the market is anticipated to expand, with a projected growth rate of 12% annually. This trend indicates a shift in patient expectations, where the demand for cutting-edge medical solutions is likely to drive further advancements in the 3d printed-medical-implants market.

Rising Demand for Personalized Healthcare Solutions

The shift towards personalized healthcare is significantly influencing the 3d printed-medical-implants market. Patients increasingly seek implants that cater to their unique anatomical requirements, leading to a growing preference for customized solutions. In France, this trend is reflected in the increasing collaboration between healthcare professionals and manufacturers to develop tailored implants. The market is projected to grow by approximately 20% over the next five years, driven by this demand for personalization. As healthcare systems evolve, the ability to produce bespoke implants quickly and efficiently will likely become a key competitive advantage for companies operating in the 3d printed-medical-implants market.