Automotive Industry Innovations

The automotive industry in China is undergoing rapid transformation, with a strong emphasis on innovation and efficiency. The laser cladding market is poised to benefit from this trend, as manufacturers seek to improve the performance and longevity of vehicle components. The integration of laser cladding technology allows for the creation of wear-resistant surfaces, which is essential for high-performance vehicles. Recent data indicates that the automotive sector accounts for approximately 30% of the overall demand for laser cladding services in China. As electric vehicles gain traction, the need for advanced materials and coatings will likely drive further growth in the laser cladding market, potentially increasing its market share by 20% in the coming years.

Rising Demand in Aerospace Sector

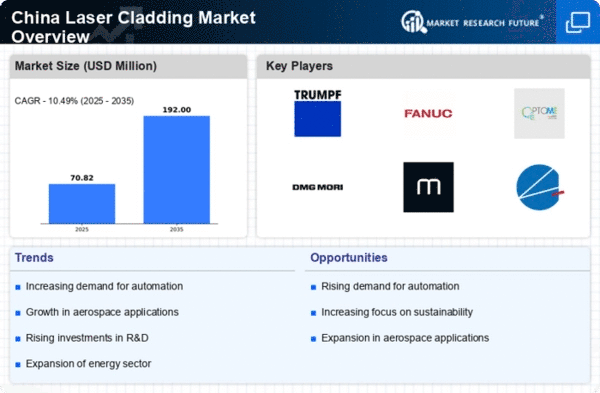

The aerospace sector in China is experiencing a notable surge in demand for advanced manufacturing techniques, including the laser cladding market. This technology is increasingly utilized for repairing and enhancing components, which is crucial for maintaining aircraft performance and safety. The Chinese government has been investing heavily in the aerospace industry, aiming to increase its market share globally. As a result, This market is projected to grow significantly., with estimates suggesting a compound annual growth rate (CAGR) of around 15% over the next five years. This growth is driven by the need for lightweight, durable materials that can withstand extreme conditions, making laser cladding an attractive option for manufacturers in this sector.

Expansion of Industrial Applications

The industrial applications of laser cladding technology are expanding rapidly in China, driven by the need for enhanced performance and durability in various sectors. Industries such as oil and gas, mining, and power generation are increasingly adopting laser cladding to improve the lifespan of critical components. This trend is indicative of a broader shift towards advanced manufacturing techniques that prioritize efficiency and reliability. Recent estimates suggest that the industrial sector could account for over 40% of the total market for laser cladding services in China. As these industries continue to evolve and seek innovative solutions, the laser cladding market is likely to experience robust growth, with projections indicating a potential market size increase of 15% annually.

Increased Focus on Energy Efficiency

Energy efficiency has become a critical concern for industries in China, prompting a shift towards more sustainable manufacturing practices. The laser cladding market is well-positioned to address these concerns, as the technology allows for precise material application, reducing waste and energy consumption. By utilizing laser cladding, manufacturers can achieve better material utilization, which is essential in an era where resource conservation is paramount. This trend is likely to resonate with industries looking to enhance their sustainability profiles, potentially leading to a 30% increase in demand for laser cladding services. As companies strive to meet regulatory requirements and consumer expectations regarding environmental impact, the laser cladding market may see accelerated growth.

Government Support and Policy Initiatives

The Chinese government has implemented various policies to support advanced manufacturing technologies, including those related to the laser cladding market. Initiatives aimed at promoting research and development in this field are expected to enhance the competitiveness of domestic manufacturers. Financial incentives, such as grants and subsidies, are being offered to companies that adopt innovative technologies, which could lead to a substantial increase in the adoption of laser cladding processes. Furthermore, the government's focus on upgrading manufacturing capabilities aligns with the objectives of the laser cladding market, suggesting a favorable environment for growth. Analysts predict that these supportive measures could result in a market expansion of approximately 25% over the next five years.