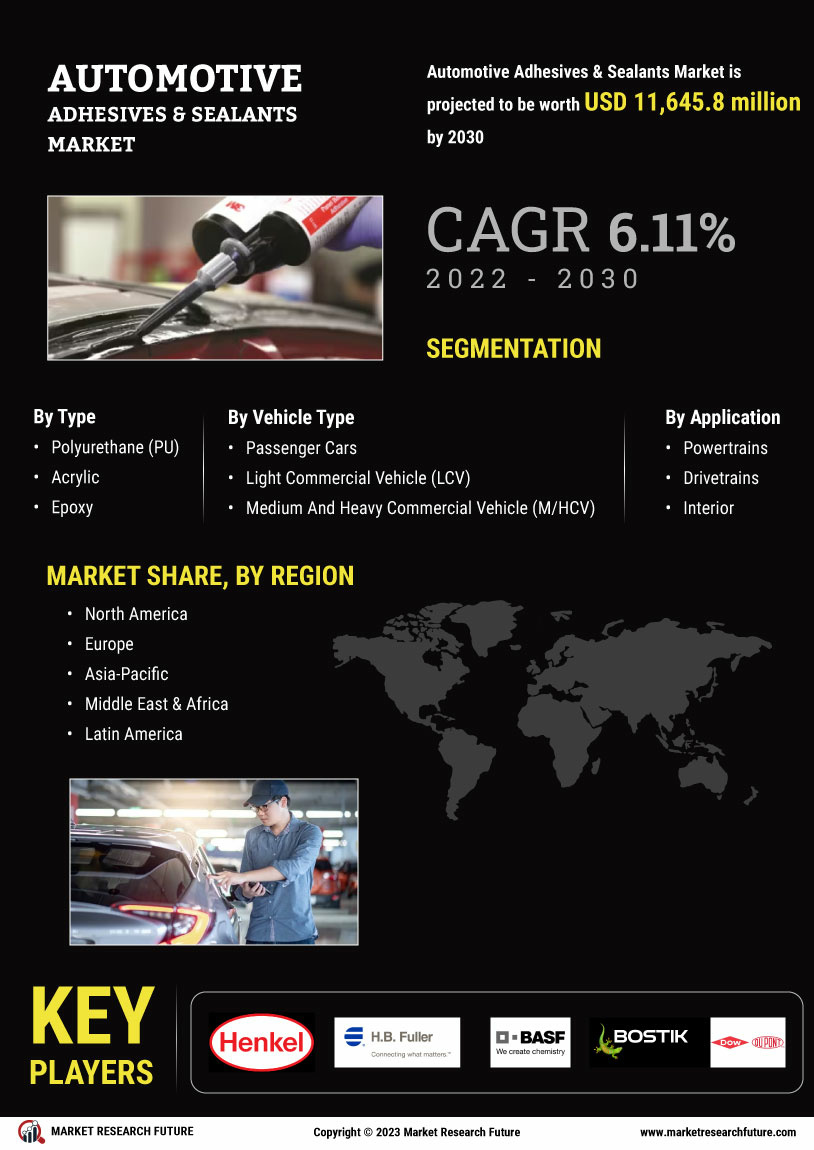

Market Growth Projections

The Global Automotive Adhesives and Sealants Market Industry is projected to experience steady growth over the next decade. The market is expected to reach a value of 11.8 USD Billion in 2024, with further growth anticipated to 15.7 USD Billion by 2035. This growth trajectory indicates a compound annual growth rate of 2.58% from 2025 to 2035. Factors contributing to this growth include the increasing demand for lightweight materials, advancements in adhesive technologies, and the rising production of electric vehicles. These projections suggest a robust and evolving market landscape, driven by innovation and changing consumer preferences.

Rising Electric Vehicle Production

The surge in electric vehicle production is a pivotal driver for the Global Automotive Adhesives and Sealants Market Industry. As the automotive sector shifts towards electrification, the demand for specialized adhesives and sealants tailored for electric vehicles is on the rise. These materials are essential for battery assembly, thermal management, and lightweight construction, contributing to overall vehicle efficiency. With electric vehicle sales projected to increase significantly in the coming years, the adhesive market is expected to benefit from this trend. The anticipated growth in electric vehicle production will likely enhance the market's value, supporting the forecasted CAGR of 2.58% from 2025 to 2035.

Growing Demand for Lightweight Materials

The Global Automotive Adhesives and Sealants Market Industry experiences a notable increase in demand for lightweight materials in vehicle manufacturing. As automotive manufacturers strive to enhance fuel efficiency and reduce emissions, the adoption of lightweight materials such as composites and plastics becomes essential. Adhesives and sealants play a crucial role in bonding these materials, ensuring structural integrity while minimizing weight. This trend is expected to propel the market, with projections indicating a market value of 11.8 USD Billion in 2024. The shift towards lightweight vehicles aligns with global sustainability goals, further driving the adoption of advanced adhesive solutions.

Market Dynamics and Competitive Landscape

The Global Automotive Adhesives and Sealants Market Industry is characterized by dynamic market conditions and a competitive landscape. Various players are actively engaged in research and development to introduce innovative adhesive solutions that cater to evolving automotive needs. This competitive environment fosters collaboration between manufacturers and automotive companies, leading to the development of customized adhesive formulations. Additionally, mergers and acquisitions among key industry players are likely to reshape market dynamics, enhancing product offerings and expanding market reach. Such strategic initiatives may contribute to the overall growth of the market, ensuring its resilience in a rapidly changing automotive landscape.

Regulatory Compliance and Safety Standards

The Global Automotive Adhesives and Sealants Market Industry is significantly impacted by stringent regulatory compliance and safety standards. Governments worldwide are implementing regulations that mandate the use of environmentally friendly and safe materials in automotive manufacturing. This regulatory landscape drives manufacturers to adopt adhesives and sealants that meet these standards, thereby promoting the use of sustainable and non-toxic formulations. As a result, the market is likely to expand as manufacturers invest in compliant adhesive technologies. The increasing focus on safety and environmental impact aligns with global trends, suggesting a robust growth trajectory for the industry.

Technological Advancements in Adhesive Formulations

Technological innovations in adhesive formulations significantly influence the Global Automotive Adhesives and Sealants Market Industry. The development of high-performance adhesives that can withstand extreme temperatures, vibrations, and environmental conditions enhances the durability and reliability of automotive components. For instance, advancements in polyurethane and epoxy adhesives have led to improved bonding capabilities, making them suitable for various applications, including structural bonding and sealing. As automotive manufacturers increasingly seek to improve vehicle performance and longevity, the demand for these advanced adhesive solutions is likely to rise, contributing to a projected market growth to 15.7 USD Billion by 2035.