- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

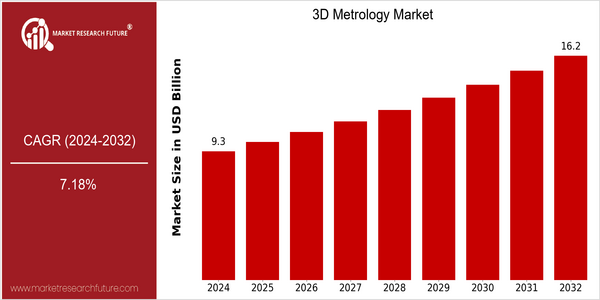

| Year | Value |

|---|---|

| 2024 | USD 9.3 Billion |

| 2032 | USD 16.2 Billion |

| CAGR (2024-2032) | 7.18 % |

Note – Market size depicts the revenue generated over the financial year

3D Metrology Market is projected to grow at a CAGR of 7.5% from 2018 to 2032. This CAGR of 7.1% will be witnessed over the forecast period of 2018 to 2032. This is mainly due to the increasing demand for precision measurements in various industries such as automobile, aerospace, and manufacturing. In order to meet the demand for high-quality products and increased operational efficiency, it is necessary to adopt advanced metrology solutions. The integration of machine learning and artificial intelligence in metrology systems is expected to propel the market growth in the near future. These innovations will lead to improved accuracy and real-time data analysis, thereby making the 3D metrology systems more useful for the manufacturers. The leading players in the 3D metrology market such as Hexagon AB, Zeiss, and Nikon Metrology are investing in research and development, strategic collaborations, and new product launches to enhance their product portfolio. Recent developments such as the collaboration between Hexagon AB and GE Measurement & Control to develop next-generation metrology solutions show the commitment of the industry to meet the evolving needs for precision measurement across various industries.

Regional Market Size

Regional Deep Dive

The three-dimensional metrology market is experiencing significant growth in various regions. This is mainly due to the technological developments, increasing demand for precise measurements and the integration of automation in manufacturing processes. North America is characterized by the presence of a large number of major players and a strong focus on innovation, while Europe is characterized by a focus on compliance and quality assurance. The Asia-Pacific region is experiencing rapid industrialization, which is promoting the use of three-dimensional metrology solutions. Middle East and Africa are gradually adopting these solutions, supported by government initiatives to develop manufacturing. Latin America, although still emerging, is beginning to recognize the importance of metrology for product quality and competitiveness.

Europe

- The European Union's stringent regulations on product quality and safety are fostering a robust market for 3D metrology, with companies like Nikon Metrology and Mitutoyo at the forefront of providing compliant solutions.

- Recent innovations in portable 3D scanning technologies are making metrology more accessible for small and medium-sized enterprises, thereby expanding the market reach across various industries.

Asia Pacific

- Rapid industrialization in countries like China and India is significantly increasing the demand for 3D metrology solutions, with local companies such as Wenzel Group and AICON 3D Systems gaining traction.

- Government initiatives aimed at boosting manufacturing capabilities, such as 'Make in India,' are encouraging investments in advanced metrology technologies to enhance production efficiency and quality.

Latin America

- Countries like Brazil and Mexico are beginning to invest in 3D metrology technologies to improve their manufacturing processes, driven by a need for higher quality standards in exports.

- The rise of local manufacturing hubs is creating opportunities for 3D metrology providers to establish a presence and cater to the growing demand for precision measurement solutions.

North America

- The adoption of Industry 4.0 principles is driving the demand for advanced 3D metrology solutions, with companies like Hexagon and Zeiss leading the charge in innovation and product development.

- Regulatory changes in manufacturing standards, particularly in the aerospace and automotive sectors, are pushing organizations to invest in 3D metrology technologies to ensure compliance and enhance quality control.

Middle East And Africa

- The UAE's Vision 2021 initiative is promoting the adoption of advanced manufacturing technologies, including 3D metrology, to diversify the economy and improve industrial output.

- Emerging partnerships between local firms and international technology providers are facilitating knowledge transfer and the implementation of cutting-edge metrology solutions in the region.

Did You Know?

“Did you know that 3D metrology can reduce production errors by up to 90%, significantly enhancing product quality and operational efficiency?” — Metrology Research Institute

Segmental Market Size

The 3D metrology market is growing steadily, driven by the increasing demand for precise measurements in a number of industries, such as aerospace, automobile, and manufacturing. The factors driving this market are the rising need for quality assurance and compliance with stringent regulatory standards, and advancements in automation and digitalization, which have enhanced measurement accuracy and efficiency. Hexagon and Zeiss are at the forefront of this trend, developing new, innovative solutions to meet these needs. In the developed economies, such as North America and Europe, 3D metrology is already a well-established industry. For instance, 3D scanning is an integral part of the product development and quality assurance processes at Ford, which uses it to inspect the accuracy of components. Moreover, trends such as the growing focus on sustainability and the increasing complexity of manufacturing processes are also driving growth. The latest developments in metrology, such as laser scanning and photogrammetry, have made it possible to make more accurate measurements more quickly.

Future Outlook

From 2024 to 2032, the 3D metrology market is expected to grow at a CAGR of 7.18% from a value of $9.3 billion to $16 billion. This growth is due to the growing demand for precise measurements in a variety of industries, such as the aircraft, automobile and manufacturing industries. As companies continue to focus on quality control and efficiency, the penetration of 3D metrology solutions is expected to increase. The penetration rate in the main industries could reach over 30% in 2032. Moreover, technological innovations, especially in the fields of automation and artificial intelligence, will radically change the 3D metrology landscape. Laser scanning, optical measurement and integrated software solutions will improve the accuracy of measurements and reduce the cost of operating 3D metrology systems. Government initiatives to promote the development of advanced manufacturing and the application of new technology will also spur growth. The Internet of Things and 3D printing will also play a critical role in the future of the market. 3D metrology is a major part of the modern quality assurance and manufacturing process.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 8 Billion |

| Market Size Value In 2023 | USD 8.6 Billion |

| Growth Rate | 8.20% (2023-2032) |

3D Metrology Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.