Summary Overview

Lubricants and Greases Market Overview

The global Lubricants and Greases market is witnessing strong growth, fueled by increasing demand from sectors such as electric vehicles (EVs), renewable energy systems, pharmaceuticals, and high-tech electronics manufacturing. This market comprises a wide network of suppliers and manufacturers offering high-performance synthetic lubricants, lithium-based greases, and specialty additives that are critical for equipment protection, battery efficiency, precision manufacturing, and chemical stability in advanced industrial processes.

Our report delivers a detailed examination of procurement trends, with emphasis on cost management, supplier diversification, and the integration of digital technologies to enhance operational agility across production, warehousing, distribution, and supply chain workflows. Key upcoming challenges in the procurement of lubricants and greases include navigating volatile raw material pricing, particularly for base oils, lithium, and metallic additives, maintaining the resilience of global supply chains, and meeting increasingly rigorous quality and environmental compliance standards across regions.To stay ahead, companies are deploying smart sourcing practices, investing in blockchain traceability, AI-based demand forecasting, and leveraging real-time market intelligence platforms to optimize purchasing decisions. As global demand surges, organizations are also focused on risk mitigation strategies, enhancing supply visibility, and ensuring access to consistent, high-quality lubricant and grease products that meet evolving application-specific requirements.

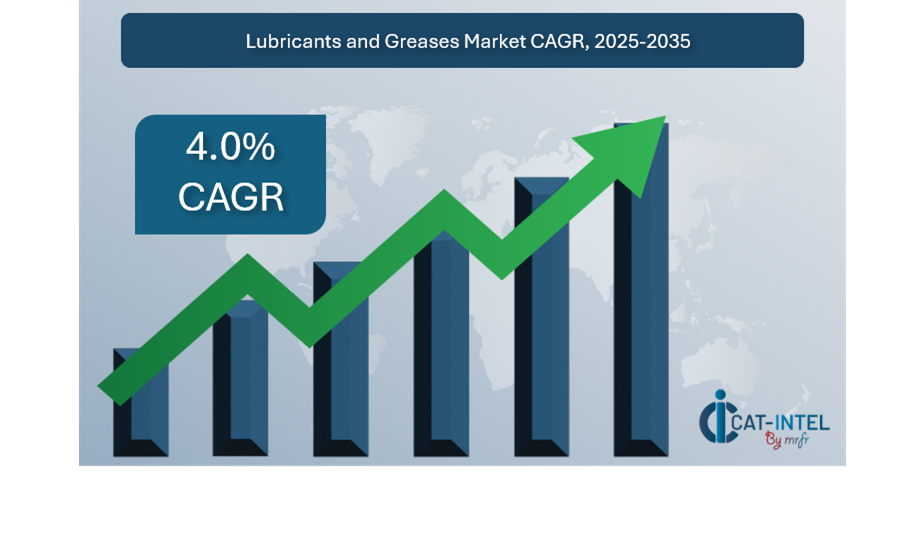

Market Size: The global Lubricants and Greases market is projected to reach USD 250 billion by 2035, growing at a CAGR of approximately 4.0% from 2025 to 2035.

Growth Rate: 4.0%

-

Sector Contributions: Growth in the market is driven by: -

Rising Demand for Advanced Energy Solutions: The rapid adoption of vehicles is significantly increasing the need for high-performance lubricants and greases.

-

Industrial Expansion: The expansion of industrial manufacturing and production is accelerating the use of specialty lubricants and greases for precision equipment.

-

Technological Transformation: Advancements in lubricant formulation technologies and automated blending processes are improving product consistency, reducing production waste.

-

Product Innovation: The integration of automated processing lines is reducing contamination risks, and boosting output in production facilities handling sensitive lithium and organometallic materials.

-

Investment Initiatives: Leading companies are investing in advanced research, AI-driven quality control systems, and sustainable production technologies.

-

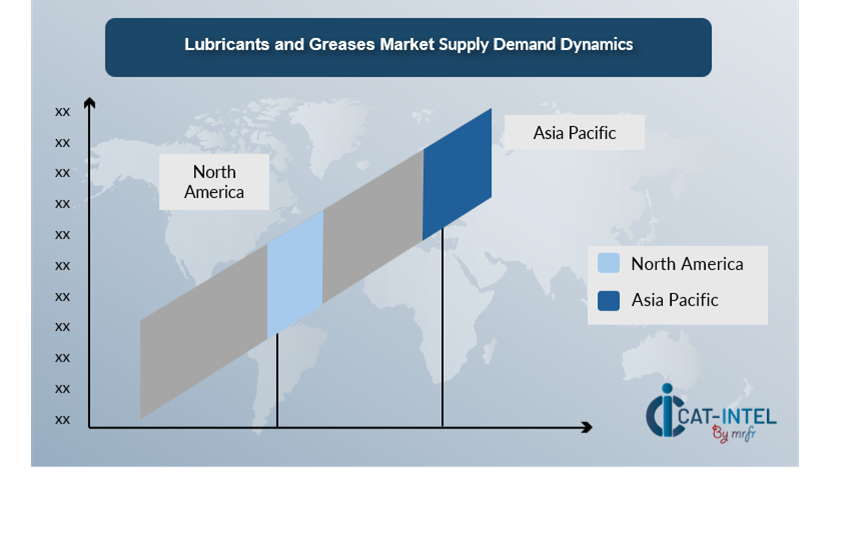

Regional Insights: Asia-Pacific & North America remain key regions for Lubricants and Greases, require specialized lubrication solutions to support precision and reliability

Key Trends and Sustainability Outlook:

-

Digital Integration: The lubricants and greases industry is rapidly adopting digitalization and automation across critical processes such as formulation development, quality assurance.

-

Sustainability Focus: A shift toward greener synthesis routes, reducing reliance on toxic solvents or heavy metals.

-

Customer-Centric Delivery Models: As customer expectations rise, companies are adopting flexible delivery schedules and more personalized solutions.

-

Smart Inventory: Predict customer demand based on industry cycles (e.g., automotive battery production, semiconductor trends).

Growth Drivers:

-

Sector Expansion: The growing volume of vehicles and machineries is driving demand for efficient services.

-

Customer Experience Expectations: Increasing demand for faster, more reliable, and more transparent options with new advance technology.

-

Sustainability Goals: The pressure to adopt environmentally friendly practices is shaping the services landscape, with many providers focusing on sustainable methods.

-

Technological Advancements: Adoption of new technologies, such as automation, AI, and IoT, is improving Lubricants and greases efficiency and helping companies stay competitive.

Overview of Market Intelligence Services for the Lubricants and Greases Market:

Recent analyses have identified key challenges such as rising shipping costs, changing consumer expectations, and fluctuating demand. Market intelligence services provide actionable insights that help companies optimize their logistics procurement strategies, identify cost-saving opportunities, and enhance supply chain resilience. These insights also support companies in complying with regulations and maintaining high standards of service while managing costs effectively.

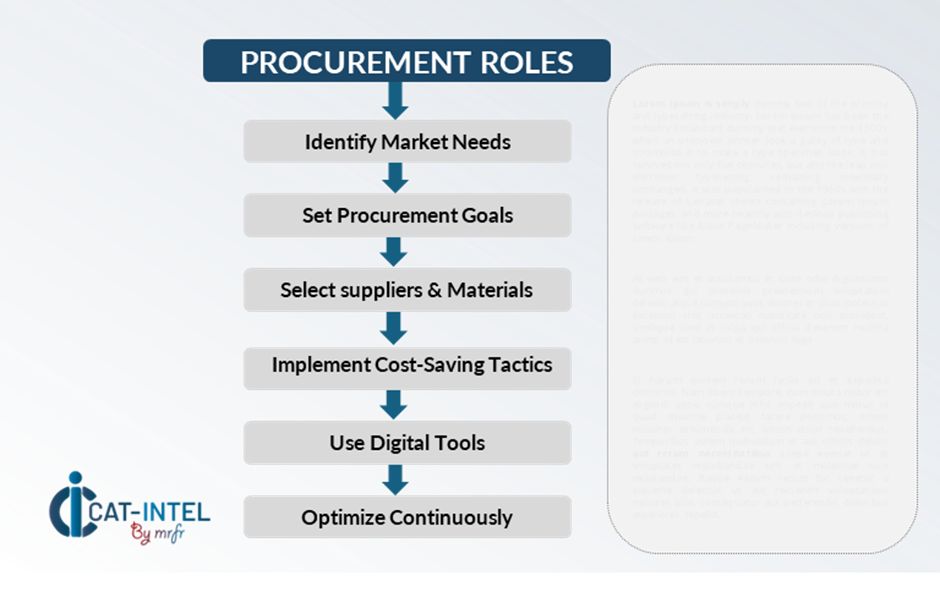

Procurement Intelligence for Lubricants and Greases: Category Management and Strategic Sourcing

To stay competitive in the Lubricants and Greases market, companies are streamlining their procurement processes using spend analysis and supplier performance tracking. Effective category management and strategic sourcing are essential for reducing procurement costs and ensuring consistent, high-quality service delivery. By leveraging market intelligence, businesses can refine their procurement strategies and negotiate favourable terms for logistics services, ensuring timely delivery and customer satisfaction while optimizing costs.

Pricing Outlook for Lubricants and Greases: Spend Analysis

The pricing outlook for Lubricants and Greases is expected to remain dynamic, influenced by various factors that affect both operational and service delivery costs. Key drivers of pricing trends include fluctuations in fuel and transportation expenses, labor costs, technological advancements in automation, and increasing demands for faster delivery times. Additionally, the rising need for sustainable packaging solutions and carbon-neutral delivery services is contributing to cost pressures.

Efforts to optimize procurement processes, improve supplier relationships, and adopt advanced technology solutions are crucial for managing costs effectively. Leveraging digital tools for real-time monitoring, route optimization, and inventory management can further enhance cost efficiency.

Partnering with reliable logistics service providers, negotiating long-term contracts, and streamlining operational workflows are essential strategies to maintain cost control in the e-commerce logistics sector. Despite these challenges, maintaining high service standards, reducing delivery times, and investing in automation will be key to sustaining profitability.

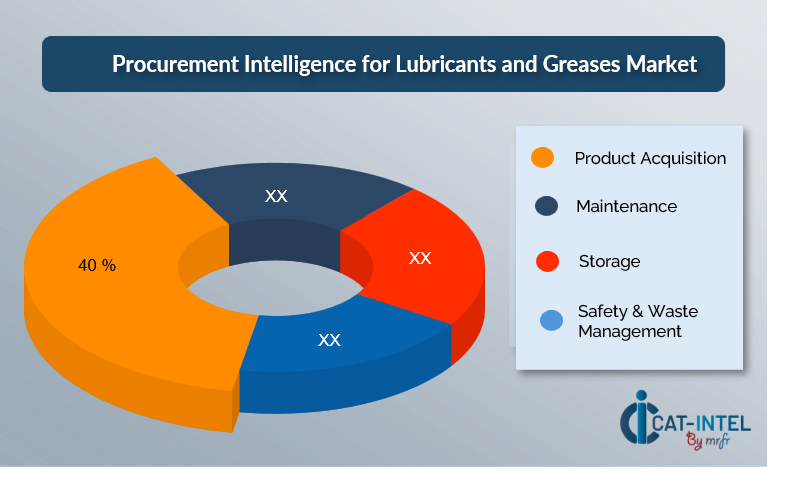

Cost Breakdown for Lubricants and Greases: Total Cost of Ownership (TCO) and Cost-Saving Opportunities

-

Product Acquisition (40%)

-

Description: The largest cost in Lubricants and Greases comes from Product acquisition. -

Trends: The adoption of new technology and autonomous systems is helping companies reduce labour costs and enhance efficiency.

- Maintenance (XX%)

- Storage (XX%)

- Safety & Waste Management (XX%)

Cost-Saving Opportunities: Negotiation Levers and Purchasing Negotiation Strategies

In the Lubricants and Greases industry, optimizing procurement processes and utilizing effective negotiation tactics can drive significant cost savings while enhancing service efficiency. Key strategies for achieving cost reductions include establishing long-term partnerships with logistics service providers, particularly in strategic regions, to secure better pricing, volume discounts, and more favorable terms for shipping and delivery.

Negotiation levers such as bulk purchasing, consolidating shipments, and securing forward contracts can help mitigate the effects of fluctuating transportation costs and supply chain disruptions. Companies can also negotiate for flexible delivery schedules or volume-based pricing that supports both operational needs and cost control.

Working with logistics providers that emphasize sustainability, and operational innovation can offer additional benefits, including access to eco-friendly delivery options and cost savings driven by improved efficiency in routing and warehouse management.

Supply and Demand Overview for Lubricants and Greases: Demand-Supply Dynamics and Buyer Intelligence for Effective Supplier Relationship Management (SRM)

The Lubricants and Greases market is experiencing accelerated growth, driven by increasing demand from sectors such as vehicles energy storage, electronics, pharmaceuticals, and advanced materials. Balancing supply and demand in this sector require close attention to material availability, logistics efficiency, regulatory landscapes, and technological advancements.

Demand Factors:

-

Vehicles and Machinery Expansion: The rise in vehicles and Machinery is increasing the demand for specialized lubricants and thermal management greases. -

Advanced Manufacturing: Industries like advanced manufacturing production are driving demand for ultra-clean, non-reactive lubricants and NSF-certified greases. -

Sustainability Initiatives: Buyers are increasingly favoring suppliers that align with green chemistry practices, low-carbon lithium sourcing, and responsible waste management. -

Customization Requirements: Different industries require tailored formulations, custom solvent systems, or special handling protocols.

Supply Factors:

-

Transportation Infrastructure: The availability and efficiency of transportation networks, including road, rail, and air freight, significantly influence the supply of logistics services. -

Technological Advancements: Integration of AI, IoT, and automation in warehouse management, route optimization, and fleet management is improving the reliability and cost-effectiveness of services. -

Global Trade and Regulatory Challenges: Export/import of certain lubricant additives or base oils may be restricted or heavily regulated in some regions due to environmental concerns. -

Labor Availability: The production and distribution require trained professionals with deep expertise in tribology, chemistry, and quality assurance.

Regional Demand-Supply Outlook: Lubricants and Greases

Asia Pacific: Dominance in Lubricants and Greases

The region is expected to dominate the lubricant market, driven by rapid adoption of vehicles and machinery solutions. China's increasing demand is a significant factor influencing global supply chains.

-

High Production Capacity and Infrastructure: Strong industrial zones and port infrastructure enable the efficient global export of lubricants, base oils, and specialty greases.

-

Technological Integration: Integration of automation in lubrication extraction and refining processes, combined with AI-driven logistics platforms, improves throughput and real-time supply chain visibility.

-

Retail Growth: The rise of digital platforms and the automotive and industrial maintenance sectors is driving demand for consumer-packaged lubricants and maintenance kits.

-

Sustainability Focus: Industry leaders are increasingly adopting green logistics practices, such as deploying electric delivery fleets, low-emission warehouse operations.

Supplier Landscape: Supplier Negotiations and Strategies

The supplier ecosystem for lubricants and greases is diverse and highly competitive, consisting of a mix of global manufacturers, regional distributors, and niche specialty providers. These suppliers influence key market factors such as product pricing, formulation innovation, delivery timelines, and technical support quality.

The supply chain also includes logistics and distribution partners who are critical to ensuring the timely and compliant delivery of lubricant products. Major logistics companies provide end-to-end distribution solutions, including bulk lubricant transport, warehousing, and cross-border trade services. Meanwhile, smaller, specialized providers focus on last-mile delivery, temperature-sensitive lubricants, hazardous material compliance, and eco-friendly packaging.

Key suppliers in the Lubricants and Greases market include:

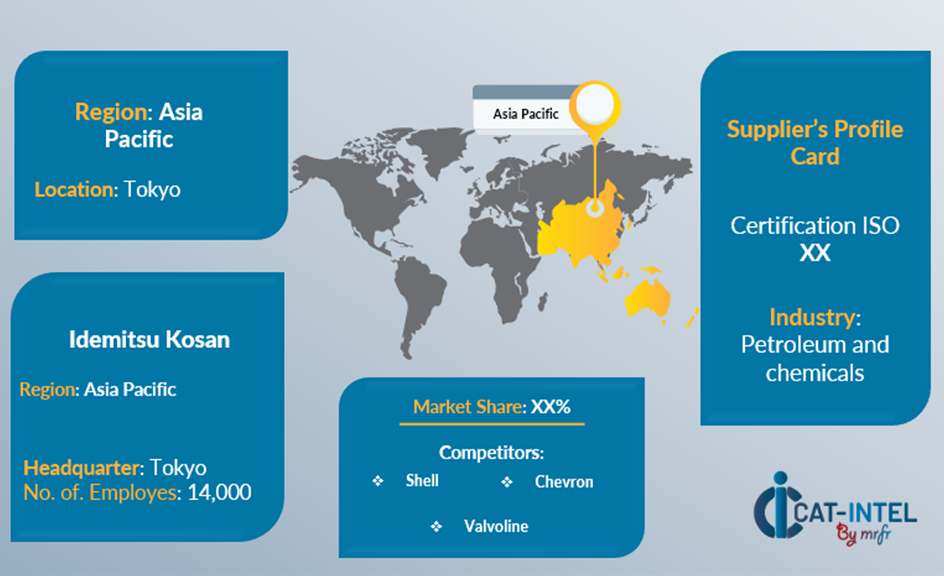

- Idemitsu Kosan

- ExxonMobil

- Shell

- BP (Castrol)

- Chevron

- TotalEnergies

- Fuchs Petrolub

- Lubrizol Corporation

- Kluber Lubrication

- Valvoline

Key Developments Procurement Category Significant Development

Significant Development |

Description |

Market Growth |

The Lubricants and Greases market is expanding rapidly due to the increasing volume of vehicles, and machinery particularly in emerging markets. |

Sustainability Focus |

There is a growing emphasis on environmentally friendly services, with an increasing demand for recyclable packaging, and carbon-neutral methods. |

Product Innovation |

High-performance, sustainable formulations that enhance efficiency, reduce environmental impact, and meet evolving industrial and automotive demands. |

Technological Advancements |

The new technology to drive smarter formulations, real-time monitoring, and automation to improve performance, durability, and maintenance efficiency. |

Global Trade Dynamics |

These is shaped by shifting supply chains, regional regulations, and fluctuating crude oil prices influencing import-export flows and market competitiveness. |

Customization Trends |

Tailored formulations to meet specific industry needs, equipment requirements, and performance expectations across diverse applications. |

|

Lubricants and Greases Attribute/Metric |

Details |

Market Sizing |

The global Lubricants and Greases market is projected to reach USD 250 billion by 2035, growing at a CAGR of approximately 4.0% from 2025 to 2035. |

Lubricants and Greases Technology Adoption Rate |

Around 50% of companies are adopting advanced technologies like AI, machine learning, and IoT for route optimization. |

Top Lubricants and Greases Industry Strategies for 2025 |

Key strategies include expanding sustainable product lines, investing in R&D for advanced formulations, optimizing supply chains, and forming strategic partnerships for global growth. |

Lubricants and Greases Process Automation |

Approximately 45% of companies have implemented automation in warehousing, sorting, and packaging to enhance efficiency and reduce costs. |

Lubricants and Greases Process Challenges |

Maintaining formulation stability, managing raw material variability, meeting stringent environmental regulations, ensuring consistent quality, and optimizing production efficiency at scale. |

Key Suppliers |

Leading players in the market include Idemitsu Kosan, ExxonMobil, Shell, BP (Castrol), Chevron |

Key Regions Covered |

Prominent regions include, Asia-Pacific, North America and Europe, driven by the growing sector and technological advancements. |

Market Drivers and Trends |

Growth is driven by the rising demand from automotive and industrial sectors, a shift toward eco-friendly and synthetic products, advancements in machinery requiring high-performance lubricants. |