Summary Overview

Lotion Pumps Market Overview:

The global lotion pumps market is steadily expanding, driven by increased demand in industries such as personal care, cosmetics, healthcare, and home items. This dynamic industry encompasses a wide range of pump types and dispensing methods, from traditional screw-on pumps to airless and foam-dispensing systems. Our paper offers a thorough examination of procurement trends, with an emphasis on cost-cutting techniques and the use of innovative manufacturing and supply chain tools to optimize operations and speed product delivery.

Looking ahead, key procurement challenges include controlling production and tooling costs, assuring scalability for varied product lines, maintaining rigorous quality and safety requirements, and efficiently integrating new technologies into current manufacturing ecosystems. As global demand continues to climb, adaptability and innovation remain critical for long-term success in the lotion pumps industry.

Market Size: The global Lotion Pumps market is projected to reach USD 2.85 billion by 2035, growing at a CAGR of approximately 6.54% from 2025 to 2035.

Growth Rate: 6.54%

-

Sector Contributions: Growth in the market is driven by: -

Manufacturing & Supply Chain Optimization: There is a rising emphasis on real-time data integration and optimized production processes to improve productivity and shorten time-to-market.

-

Retail and E-Commerce Growth: The fast proliferation of e-commerce and direct-to-consumer models is driving up demand for lotion pumps with personalized packaging and short replenishment cycles.

-

Technological Transformation: Automation, precision manufacturing, and material science are altering the lotion pump scene.

-

Product Design Innovations: By moving toward modular, sustainable, and adaptable pump solutions, manufacturers may better service a wide range of sectors.

-

Investment Initiatives: Companies are expanding their investments in smart manufacturing and cloud-based production monitoring technologies to minimize infrastructure costs and allow real-time cooperation.

-

Regional Insights: North America and Asia Pacific lead the market, owing to strong manufacturing capabilities, growing consumer demand, and growing awareness of sustainable packaging alternatives.

Key Trends and Sustainability Outlook:

-

Sustainable Materials: Increased usage of recyclable and biodegradable plastics to accord with global sustainability regulations and customer preferences.

-

Smart Pumps: The integration of IoT-enabled pumps for precise dispensing, particularly in healthcare and personal care applications.

-

Customization Trends: There is a growing need for brand-specific designs and industry-focused versions in industries such as cosmetics, pharmaceuticals, and hotels.

-

Digital Integration: Using smart industrial tools to do real-time data analytics, measure performance, and improve operational transparency.

-

Circular Supply Chains: Closed-loop solutions and environmentally friendly logistics are prioritized for a more sustainable industrial lifespan.

Growth Drivers:

-

Digital Transformation: The use of digital technologies in manufacturing and logistics improves speed, accuracy, and quality in lotion pump output.

-

Automated Manufacturing: Increasing dependence on robotics and artificial intelligence to cut labour costs and eliminate faults.

-

Scalability Needs: Manufacturers are investing in scalable manufacturing lines to accommodate increasing demand without sacrificing quality.

-

Regulatory Compliance: Strict safety and packaging standards are driving innovation in material use and testing procedures.

-

Global Market Expansion: Rising demand for lotion pumps in emerging regions, along with international product rollouts, is pushing global manufacturing methods.

Overview of Market Intelligence Services for the Lotion Pumps Market:

Recent market evaluations highlight issues such as variable raw material costs, tooling lead times, and the necessity for quick design iteration. Market intelligence services give meaningful insights into procurement patterns, supplier capabilities, and competitive benchmarking, allowing firms to cut costs, optimize sourcing, and increase operational resilience.

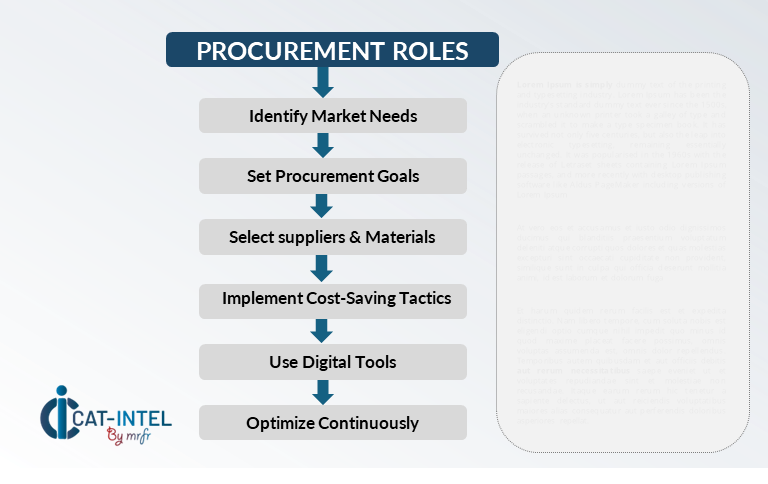

Procurement Intelligence for Lotion Pumps: Category Management and Strategic Sourcing

Companies are rethinking their procurement strategy to remain competitive, relying on category-specific spend analysis, supplier scorecards, and real-time pricing tracking. Strategic sourcing frameworks are critical for establishing dependable suppliers, enhancing negotiation outcomes, and lowering risk in the global supply chain. These insights help enable compliance with quality standards, sustainability objectives, and short product launch schedules.

Pricing Outlook for Lotion Pumps: Spend Analysis

The pricing outlook for lotion pumps is likely to be somewhat volatile, influenced by a mix of technology developments, material costs, design customization, and regional market differences. Innovations in dispensing systems, increased demand for sustainable materials, and global supply chain variations are all major pricing factors.

Graph shows general upward trend pricing for Lotion Pumps and growing demand. However, there may be fluctuations influenced by economic conditions, technological advancements, and competitive dynamic.

To manage and restrict costs, firms are focused on procurement process optimization, supplier performance review, vendor consolidation, and the implementation of modular component methods for cross-product line uniformity. Efficient contract management, such as dynamic price clauses and volume-based discounts, improves procurement efficiency.

Establishing good supplier connections and negotiating long-term agreements with dependable manufacturers are critical tactics for maintaining pricing consistency. Regardless of price problems, keeping a focus on scalable production, guaranteeing quality and regulatory compliance, and adopting automated, cost-effective manufacturing techniques will be key to profitability.

Cost Breakdown for Lotion Pumps: Total Cost of Ownership (TCO) and Cost-Saving Opportunities

1. Materials and Production: (40%)

1. Materials and Production: (40%)-

Description: This cost comprises the raw materials (plastics, metals, rubber, etc.) and manufacturing procedures involved in creating lotion pumps. It includes the cost of obtaining high-quality materials, the energy consumed during manufacture, and personnel expenditures in production facilities.

-

Trend Point: There is a rising trend toward sustainable materials and biodegradable polymers to lessen environmental effect, which may raise material prices but result in long-term cost savings.

- Packaging and Transportation: (XX%)

- Customization and Tooling: (XX%)

- Maintenance and After-Sales: (XX%)

Cost-Saving Opportunities: Negotiation Levers and Purchasing Negotiation Strategies

In the lotion pumps industry, streamlining procurement procedures and implementing strategic sourcing and negotiating strategies may result in considerable cost savings and improved operational efficiency. Long-term collaborations with reputable suppliers, particularly those with innovative, scalable manufacturing capabilities, can lead to more attractive price arrangements, such as volume discounts and bundled value-added services. Multi-year supply agreements and subscription-style manufacturing methods can help firms control costs, reduce market volatility, and increase forecasting accuracy. These solutions help cut administrative expense, allowing for more predictable budgeting.

Partnering with forward-thinking manufacturers who invest in automation, sustainable materials, and smart dispensing technologies may save long-term operational costs while increasing product innovation. These vendors frequently provide modular product lines, allowing for simpler customization and speedier time-to-market while reducing complexity. Using multi-vendor techniques and having a diverse supplier base helps to reduce risks including supply interruptions, pricing shocks, and quality discrepancies. It also increases a company's bargaining power and provides more flexibility in responding to changing market conditions.

Supply and Demand Overview for Lotion Pumps: Demand-Supply Dynamics and Buyer Intelligence for Effective Supplier Relationship Management (SRM)

The lotion pumps market is expanding steadily, fuelled by increased demand in the personal care, cosmetics, healthcare, and home product categories. Market dynamics are driven by changing customer expectations, environmental aspirations, technology improvements, and global supply chain issues.

Demand Factors:

-

Product Innovation and Customization Needs: Brands want customized, brand-specific pump designs that improve user experience, enable product distinctiveness, and comply with sector-specific standards.

-

E-Commerce and Retail Growth: The rise of direct-to-consumer models and worldwide e-commerce platforms is fuelling demand for long-lasting, cost-effective, and visually appealing pump solutions.

-

Sustainability Initiatives: The growing emphasis on recyclable and biodegradable packaging is driving demand for pumps produced from sustainable materials including post-consumer recycled plastics and bio-based polymers.

-

Operational Efficiency and Speed to Market: Brands look for suppliers who can provide flexible manufacturing capabilities and just-in-time delivery, resulting in speedier product launches and lower inventory costs.

Supply Factors:

-

Manufacturing technological Advancements: Automated molding, robotic assembly, and precise tooling, which improve supplier capabilities while lowering production costs.

-

Diverse Supplier Landscape: A combination of multinational manufacturers, regional experts, and sustainability-focused startups provide customers a variety of sourcing alternatives adapted to diverse volume, quality, and pricing needs.

-

Global Economic Conditions: Raw material price volatility, labour cost changes, energy prices, and logistical restrictions all have an influence on production timetables and pricing in different areas.

-

Scalability and Modular Manufacturing: Suppliers are using modular manufacturing methods to fulfill the demands of both large-scale and specialized product lines, which provide scalability and speedier prototyping.

Regional Demand-Supply Outlook: Lotion Pumps

The Image shows growing demand for Lotion Pumps in both Asia Pacific and North America, with potential price increases and increased Competition.

Asia Pacific: Dominance in the Lotion Pumps Market

Asia Pacific, particularly China, is a dominant force in the global Lotion Pumps market due to several key factors:

-

Growing Consumer Demand: The fast development of Asia-Pacific's personal care and cosmetics sectors, spurred by rising disposable incomes and skincare knowledge, has greatly increased demand for lotion pumps.

-

Supply Chain Infrastructure: The region has a well-established and efficient supply chain infrastructure, which includes closeness to raw material suppliers and modern manufacturing facilities.

-

Technological Advancements: To fulfill global market needs, Asia-Pacific has made major investments in automated manufacturing processes and smart packaging technologies that include advanced features.

-

Strategic Market Access and Export Capability: The Asia-Pacific area serves as a vital export hub for the global market, with established trade agreements and access to many nations globally.

-

Manufacturing Centre & Cost Efficiency: Asia-Pacific is a worldwide manufacturing center because of its cheaper labor and production costs, making the region highly competitive in terms of pricing and scalability.

Asia Pacific Remains a key hub Lotion Pumps Price Drivers Innovation and Growth.

Supplier Landscape: Supplier Negotiations and Strategies

The lotion pump supplier environment is broad and competitive, with a mix of multinational manufacturers, specialised regional competitors, and inventive niche providers. These vendors have a significant impact on price structures, product customization capabilities, sustainability practices, and service reliability. Established worldwide producers lead the industry, providing end-to-end manufacturing, design, and logistics solutions to meet high-volume demands and multinational product rollouts

In response to increased demand for speed, sustainability, and personalization, suppliers are increasingly investing in automated manufacturing and precision melding technologies, as well as extending R&D activities around material innovation and functionality upgrades. As organizations seek cost savings, faster market entrance, and more customer engagement, selecting the correct mix of global and regional suppliers has become a vital strategic choice. Supplier alliances that provide technical competence, supply chain transparency, and proactive innovation are most suited to supporting changing business and sustainability objectives.

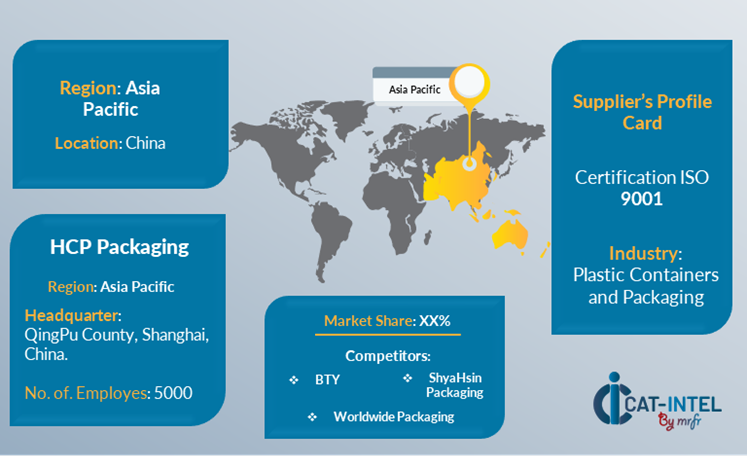

Key Suppliers in the Lotion Pumps Market Include:

- HCP Packaging

- Aptar Group, Inc.

- Silgan Dispensing Systems

- Rieke Packaging System

- GCS Packaging

- RPC Group

- Berlin Packaging

- Albéa Group

- Berk Company

- PDC Healthcare

Key Developments Procurement Category Significant Development:

Significant Development |

Description |

Market Growth |

The lotion pumps market is increasing rapidly, fueled by rising demand in the personal care, healthcare, and home sectors, particularly in emerging nations with expanding consumer goods industries. |

Cloud Adoption |

There is a noticeable movement toward eco-friendly pump solutions that use recyclable, refillable, and biodegradable materials, which aligns with global sustainability goals and changing customer preferences. |

Product Innovation |

Manufacturers are developing smart dispensing technologies, airless pump systems, and customisable components that are suited to individual product formulas and branding needs.

|

Technological Advancements |

The combination of automation, precision molding, and digital tooling improves production efficiency, resulting in shorter lead times and better-quality control. |

Global Trade Dynamics |

Changes in international trade rules, plastic component taxes, and regional sourcing strategies all have an impact on supply chain decisions and price in different regions. |

Customization Trends |

Brands require modular, design-flexible pump solutions that support their products differentiation, user experience optimization, and alignment with niche market needs. |